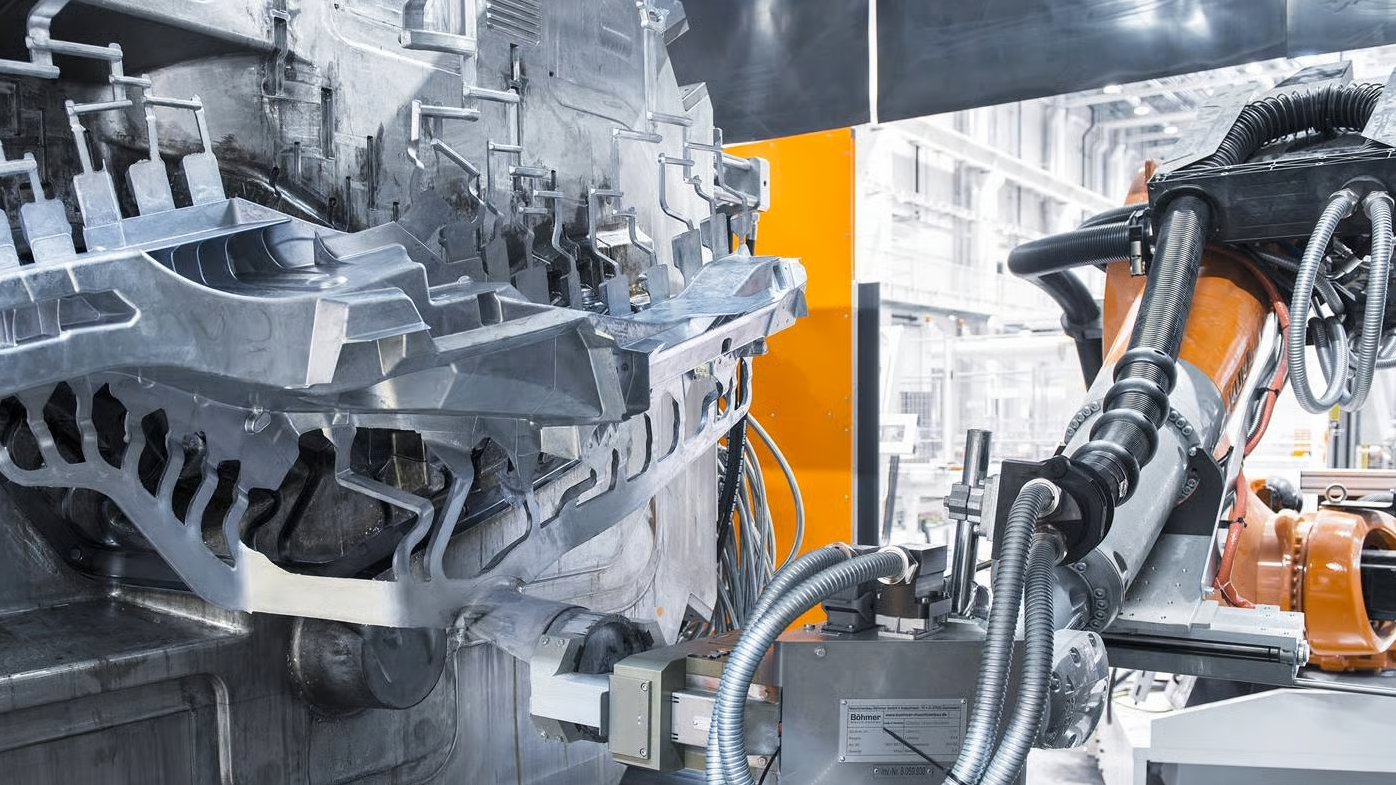

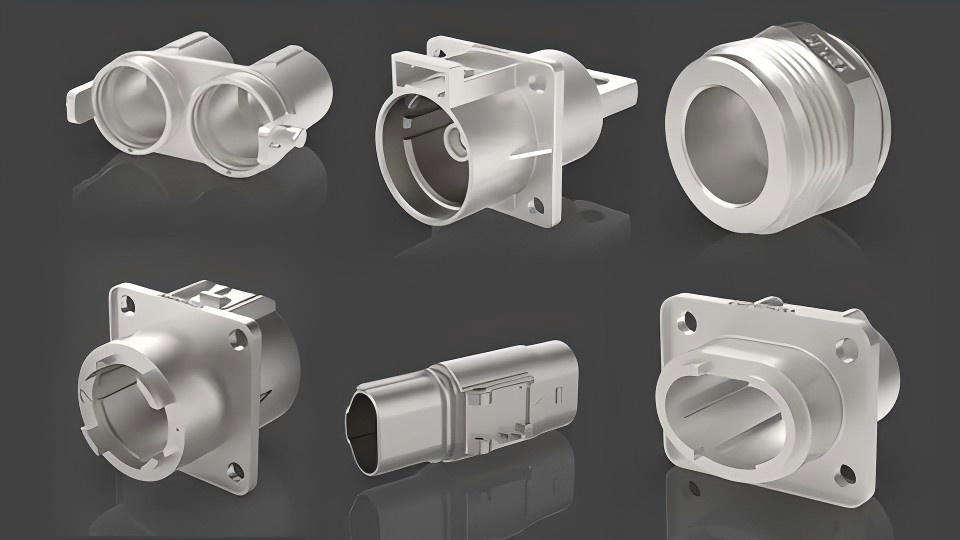

Sino Die Casting, established in 2008 in Shenzhen, China, is a high - tech enterprise that seamlessly integrates design, processing, and production. When it comes to anodized aluminum, we are at the forefront of providing top - notch solutions. Anodized aluminum offers a multitude of advantages, making it a popular choice in various industries such as automotive, new energy, robotics, and telecommunications, all of which are sectors where our services are extensively utilized. Anodizing is an electrochemical process that thickens and toughens the naturally occurring protective oxide on the surface of aluminum. This results in anodized aluminum that has enhanced corrosion resistance, which is crucial for components used in automotive applications where they are exposed to harsh environmental conditions like road salt and moisture. In the new energy sector, anodized aluminum parts can withstand the elements and ensure long - lasting performance in solar panels or wind turbine components. For robotics, the improved wear resistance of anodized aluminum allows for more durable and reliable moving parts. Our high - precision mould manufacturing, die casting, and CNC machining capabilities enable us to create aluminum parts with precise dimensions first, and then we apply the anodizing process with great accuracy. We have a team of skilled technicians who are well - versed in the anodizing process, from pre - treatment steps like cleaning and etching to the actual anodizing in the electrolyte bath and post - treatment sealing. With ISO 9001 certification, we ensure that every batch of anodized aluminum parts meets strict quality standards. Our products are exported to more than 50 countries and regions around the world, and we can provide solutions from rapid prototyping to mass production, making us a flexible and reliable partner for all your anodized aluminum needs.