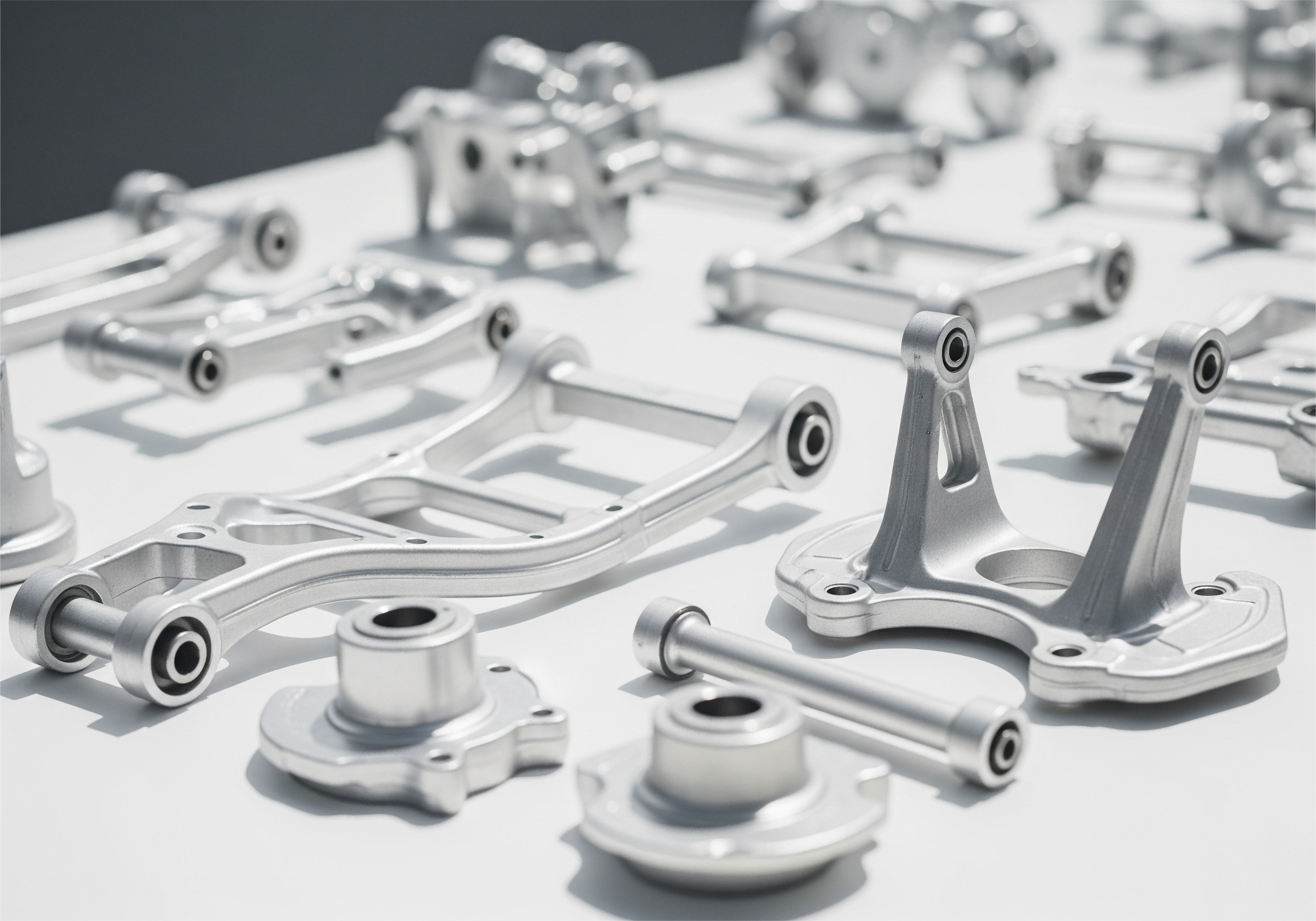

Sino Die Casting, founded in 2008 and situated in Shenzhen, China, is a high - tech enterprise that seamlessly integrates design, processing, and production. One of our core areas of expertise lies in metal surface treatment. We understand that metal surface treatment is a crucial step in enhancing the performance and aesthetics of metal components. Our services are widely applicable across multiple industries, including automotive, new energy, robotics, and telecommunications. With ISO 9001 certification, we ensure high - quality standards throughout the process. Our metal surface treatment solutions range from various methods that can improve corrosion resistance, enhance wear resistance, and provide an attractive finish. Whether it's for automotive parts that need to withstand harsh environmental conditions or telecommunications components that require long - lasting durability, our metal surface treatment processes are tailored to meet specific requirements. We have a team of skilled professionals who are well - versed in the latest techniques and use advanced equipment. From pre - treatment processes like cleaning and degreasing to the application of protective coatings, we handle every step with precision. Our goal is to provide our global clients, whose products are exported to over 50 countries and regions, with metal surface treatment solutions that not only meet but exceed their expectations, enabling them to have reliable and high - performing metal components in the market.