Kontin Alasoyi da Idanin Gudumuwa don Sauyin Halittar Daide

Samun sauyin inganci masu kyau ba tare da kuskurenke ya fara ne a wajen yankin gini. Lokacin da masu samar da suna kansada kan abubbuwa suka shiga cikin alloy mix, musamman abubbuwa kamar magnesium, silicon, da copper levels, suna kare wa sauya irin grain problems a waje. Kansada kan impurities na iya mahimmanci. Taimakawa iron content ta 0.15% ta kara tsinkayen kayan inganci. Tsarin automated degassing ta kama hydrogen level zuwa ga kira 0.1 ml per 100 grams of aluminum, wanda ke tsutsu dibé har ma karancin 0.2 ml inda porosity issues suna faru (kamar 300% zaiƙaran pores!). Sistemin da saka slag a lokacin gini suna magana matakai, amfani da hanyoyin da kayan inganci suna nemi don samar da wurin kamata a microscopic level.

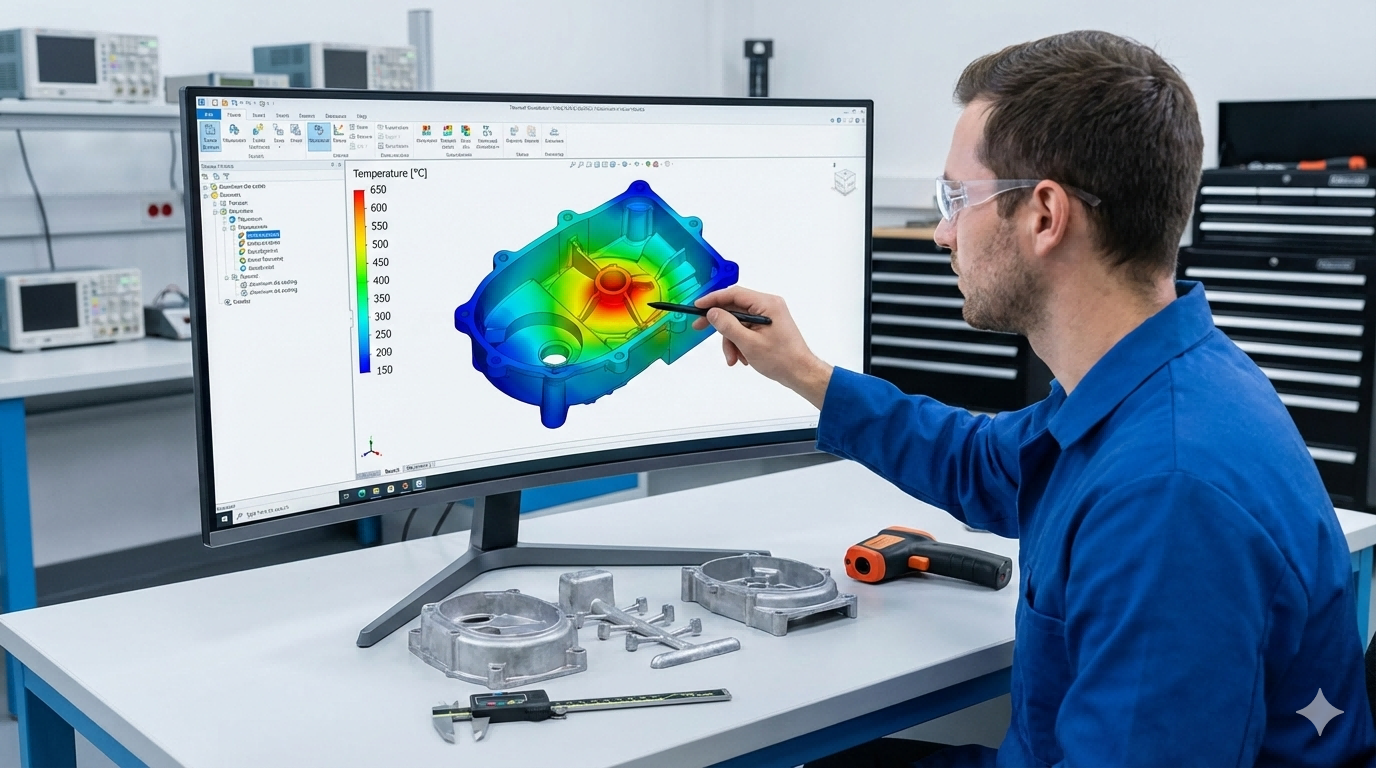

Temperature & Pressure Synchronization Across Transfer, Shot, and Cooling Stages

Samunsa nettaukar daidaita yana dogara ne a tsauraran tsari tsakanin harshen da kayan uku lokacin da ake aiki da alikali bayan koma, inganta, da lokacin hadura. Gwajin girman harshen a lokaci mai zurfi yana taimakawa wajen kiyaye harshen mutaneuwa a cikin mitattun 5 daraja Silisiyus bayan koma, wanda ke dawo da sauya zuwa matsaƙi da kuma kula da shafukan oksaydi na irin waɗannan. Lokacin inganta abubuwan dauke zuwa cungurori, canzawa harshen basuwa akan nuna cunguro yana baši don fulewa mai sauƙi ba tare da juzuwa a cikin matakan da ke tsakanin 40 zuwa 100 meter per second. Wannan ke tsayin muhimmiyar tunani saboda yana kiyaye bubuɓai na hankali da kuma kiyaye abubuwa su fito bisa girmama. Bayan cunguro ya fulo, kiyaye yadda yake hadura yana zama mahimmata. Ga abubuwan da ke iya aluminum, matakan hadura suna tsakanin 10 zuwa 15 daraja Silisiyus per second. Wannan hadurar taimako yana magana da tsarin bututu, taƙawa tsinkayar abubuwa, da kuma kara karancin harshen cikin abubuwa. Kamar yadda aka faɗaƙaƙe shi ne daga statistikin fabirkin da muka ga a cikin wasu fabrikati, lokacin da sauran daidaiton harshen da girman harshen su yi aiki tare, cold shuts sun kasance 70% kasa. Don haka wadannan masu amfani da fabirkin sun yi investma a cikin sarufa waɗanda ke kaukar duk wadannan abubuwa tare ba a matsayin abubuwa mai zurfi.

| Agogo | Alamar Mai Mahimmanci | Karin Kama da Kyau |

|---|---|---|

| Zauna | Tsawon kankiya (±5°C), sabin zaunawa | Yin wayarwa zuwa cikin abubuwa mai tsawon kankiya, haɗin oksaydi |

| Sauti | Gurbin injisyon (800–1000 bar), sabin | Raba alashan uwar hannu, saholin inganci na iko |

| Tasirin hanyar | Sabin yanke-tsawo, lokaci | Kara gurbin saukin yanke-tsawo, saka karin kankiya |

Wannan tattalin arziki na biyu ne yake tsinkaya wajen sakan karin inganci a gasar farabtar da yawa.

Tabbatar da Kowane Iyakar Tsarin: Daga Farko Mai Lafifi zuwa Kamar Kama

Iyakar kwaliti a tsibirin matsayin kankatatse da ke richi bukuku mai daji cikin tsarin yin aiki ya richi shirye-shiryen tabbatarwa da ke hada cikin tsarin yin aiki—tabbata ma'ana a baya kuma taimaka wajen kare matsalolin da za su karbi kashe.

Shirye-shiryen Tabbin Samfur (Daga Farko, Tabbata, Kamar Kama) Masu daidaitawa da ISO 9001 a Cikin Tsarin Matsayin Kankatatse

Yi nasarar haɗa da ma'auni na ISO 9001 yana nufin yin addinin goyon kwaliti a karkashin tsarin faburikasi. Goynin farko (FAI) yana duba dukkan abubuwa daga cimma zuwa kayan dare da saitin tsarin kalmomi yayin farawa zuwa faburikasi mai yawa. Waɗannan goyayen suna hada abin da ya fito ne daga cimma da abin da aka shirya a wakar. Sun gaba da goyan kai tsakanin lokuta na tsarin faburikasi. Waɗannan goyan suna faruwa a lokuta masu ilimi don hada kayan muhimmiyar da goyan kayan dare bayan an kara ko an riga, karɓar dabbarun canjin hanyoyin buƙatar. Lokacin da za a tura wasan, goyan karshe suna iya tabbatar da rashin kyau, aiki daidai, da kuma kama da duk wadannan ma'auni. Tsarin daya nan yana kirkirar rukunin alaka wa muka iya bin kaɗi da su kuma baya lafiyar bayanai game da kama'una na wasan a cikin koma. Babban baga? Ba ta karyata matakanmu na karkashin tsarin faburikasi har ma ta kama kwaliti mai zurfi.

Tacewar Masu Amfani: Aikawa Ranar Sarki, Gano Flash, da Kula da Halin Mafuta

Yin baiyan mai amfani ayyukan dubawa yana tsira abuɗan da ba wata mesini zasai yanke shi a karkashin dawo da kuskure zuwa sa'an nan. Kafin fara kowane run production, waɗannan mutane suna duba idan yaɓaddiyar release agent an nuna shi daidai a duka wurare, wanda ke tsara batutu'uka su haɗa da saurun su kuma kuwatsa waɗannan alamar da ba a so ba a sama. Lokacin da batutu'uka ana furta su daga cibiyar, masu karatu masu zinzamtarwa suna ga alamar flash iri ɗaya, wanda yau yake nufin cibiyar tana rufe ko bai da clamping pressure enough don kama masa. Lokacin da su jira tsakanin kyakkyawan production, masu amfani suna iya kula da maƙalar temperature sensors suna kula da ma duk suna ga a cibiyar, don ganin alamar zurfin ko kuskuren domin maintenance crews su san inda suka hada shigowa. Mataimakin mata ake ganin waɗannan canjin guda a cikin aiki wanda automation ba ta iya ganin sai kadan. Abubuwa kamar canje-canjen sarariyar heat ko zurfar samun narren hydraulic components ana ganin su labaran, don tsara abubuwa kamar batutu'uka porous, cold shuts, da wasu nau'ikan matsalolin dimensional a gaske.

Kare wa Tsarin Kafa ta Kafa Mai Daidaitawa: Cold Shut, Porosity, da Warping

A cikin tsarin die casting mai yawa, kawo farafin dabi'an kamar cold shut, porosity, da warping suna bukatar hanyar tsarin kafa ta kafa—ba wani aiki na musayar sauya ba. Lissafi na gorau, tabbatar da simulation, da bin sha’awa mai dabara (closed-loop) suna tsakanin kayan tsibirin kwaliti na farko.

Tsarin Gorau + Isabbaba kan Tabbatar da Cold Shut da Cracking

Ana samun rashin kuskuretsuwa lokacin da abubuwan na yanki ba su haɗu daidai ba ne saboda yawan keɓaɓen sun karfi ko akwai matsalolin tsawon girma a kan farfado. Tacewar tsawon girma tare da wadannan sensorin infrared yana baƙin abokan ginawa iya ganin yadda tsawon girma ta dace cikin ayyuka. Lokacin da su haɗu wannan bayani da kayan aiki masu zuwa masa girmar farfado, yana kara matsalar rashin kuskuretsuwa ta hanyar takambin 40% kamar yadda aka fada ta hanyar buƙatar zaman lau. Kama da farfado ya kasance mai tsawon girma (above 200 degrees Celsius) yayin da na yanki ta shigar da wurin shi yana sa duk abu su aiki kyau kuma yana kara kariyoyin saboda canjin tsawon girma a lokaci. Iyakar canza kayan aiki a lokacin da aka karɓi bayanan tsawon girman yana kama abubuwa suyi kyau kodayake cikin ayyukan ginawa masu damuwa inda kama da tsawon girma ya zama abin sha'awa ga abokan ginawa.

Haɓaka Kayan Aiki Masu Tabbatar da Simulation Don Ragu Porosity da Canjin Girma

Zaune ya faru idan gudunni suka shiga ko idan akwai goyon mai tadarta yayin da abubuwan tauna sun karkasa, wanda ke naka tsawonin tazarar da haɗarin juzu'i. Amfani da kayan aikin zane-zane na musamman yana ba da ido don duba tsarin injiktar wuya, yadda matsayi da kama yayin da ke karkasa, da tsarin gate yayin da abinci baya faru. Tace wannan hanyoyin, zai iya rage matsalolin zaune ta hanyar kamar 30% saboda bayanin sarrafa. Teknolojin digital twin tana aiki don inganta yadda gudu tafi, da yadda gudun molten ta flowa cikin molds, taimakawa wajen karkasa kyauta da inganta tasarrufin metal cikin kayan nau'ikan. Yi amfani da wannan tare da tsarin monitoring na wasabi da sensoren suna ba da bayani a lokaci, masu abincin za su iya canza tsarin karkasa a cikin milliseconds. Wannan amsawa mai kyau zai sake waɗannan matsalolin goyon da kayan dake ke koma saboda wuya bata fita daidai a cikin kayan farko.

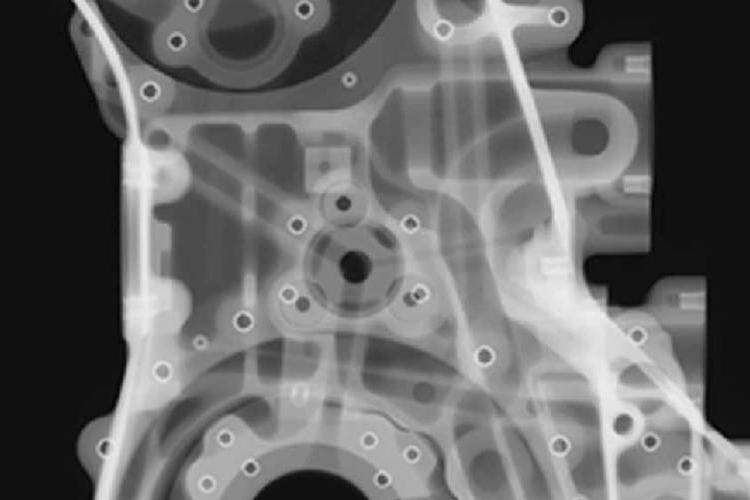

Alkawariyar da aka Kwamfitar Teknoloji: NDT, Iyakar Ayyuka, da TSarin QA na Tsibin Tsibin

Kayan wasan injin yanzu sun fara ƙare da kuskuren gano game da tsaro. Sun yi amfani da manyan teknollijin a cikin ayyukansu. Misali, X-ray da CT scans na otomitik suna duba wani abu ne a cikin rashin batutuwa ta hanyar wuta, kamar alkaruwa mai zurfi. Wannan ya kawo duk samfurannin daga cikin samar daidai, wanda ke yaushe ne a cikin kuskuren farko. Yadda aka ce, tsarin kiyasin mutuwa suna aiki ne a cikin warda. Lokacin da mutanen gano sun sami abin da ba kyau ba a lokaci guda, wannan bayani ana kika masa ga masinin injin. Sai suna canza abubuwan kamar yadda suttama injin ya shiga cikin madaidaici a cikin rabin takwas da hannu ko sai. Wannan aiki mai kyau ya kama da natsuwa mai zuwa ga karshen halitta. Laser mai zahiri yana misasa girman abubuwa a mafrashin millimeters yayin da abubuwa sun fitowa daga masini. A wancan lokaci, komputa mai maharaɗin tallafi yana duba tarihin aiki na madaidaici don fahimtar lokacin da za a buƙatar gyara kafin ya kasance abin da ya kamata. Duk wadannan yanayin teknoliji suna taimakawa wa mai tsara su iya hadawa da shawarwarron da aka sauya da sarrafun mota da sharuɗɗan kayan hanyar sama don mitun daidai na abubuwa da aka tsara kowace shekara. Abin da ake kallon kalmomi daya da biyu an samu shi shine wani aiki mai canzawa a lokacin tsaron.

Tambayoyi Masu Yawan Faruwa

Shin mutum yana da mahimmanci a sarrafa tsarin alloy a cikin die casting?

Sarrafa tsarin alloy—tare da abubuwa kamar magnesium, silicon, da copper—yana da mahimmanci saboda yana taimakawa wajen daina matsalolin grain da alamar bazu a produkatin karshe. Yadda kuma za a yi lafiya da kayan bazu, kamar hankali kan ƙarancin iron, zai sauri tsaro mai zurfi na cast.

Yaushe yaɗaɗauka tausayi ta thermal ke iya yanke tasiri kan proses din die casting?

Tausayi ta thermal tana da mahimmanci don tabbatar da sauya na metal mai neri ya dawo shiga muku ba tare da sanya daidai, wanda zai iya haifar da cold shuts da cracks. Tsarin taswira ta thermal da sauya na muku suna tabbatarwa tsakanin girman tsawon, yayin da ke kama da inganci kuma nema alamar bazu.

Wanne role inspections take ke yanzu a production mai yawa na die casting?

An gudummawa suna canzawa a cikin tsarin aiki don gabatar da sauye-sauye zuwa baya, don hana rashin iko su fito. Wannan yana hada First Article Inspections, gudummawar tafiya a lokacin haɓakar, da gudummawar karshe kafin aika, wanda ta haɗa da standaɗai na ISO 9001.

Yaushe tekunoloji taka hankali kan kontin kwaliti a cikin die casting?

Teknulogi—tare da X-ray mai iƙirƙiri, scans na CT, da sauya ‘yan yanayi—yana iya kula da dukkanin abubuwan da ke nuna rashin iko. Nukarin tsibiyoyi masu bin ka’ido suna ba da bayani masu alheri don sauya, sanya sayayyen rashin iko kamar yawa, kuma su zama tare da kokarin standaɗai na sarrafa.

Teburin Abubuwan Ciki

- Tabbatar da Kowane Iyakar Tsarin: Daga Farko Mai Lafifi zuwa Kamar Kama

- Kare wa Tsarin Kafa ta Kafa Mai Daidaitawa: Cold Shut, Porosity, da Warping

- Alkawariyar da aka Kwamfitar Teknoloji: NDT, Iyakar Ayyuka, da TSarin QA na Tsibin Tsibin

-

Tambayoyi Masu Yawan Faruwa

- Shin mutum yana da mahimmanci a sarrafa tsarin alloy a cikin die casting?

- Yaushe yaɗaɗauka tausayi ta thermal ke iya yanke tasiri kan proses din die casting?

- Wanne role inspections take ke yanzu a production mai yawa na die casting?

- Yaushe tekunoloji taka hankali kan kontin kwaliti a cikin die casting?