Asalin IATF 16949: Kanso Tsarin Har zuwa Labarin Taimakon Ganyen Die Casting

Kontrolin Sistematikin Alamar High-Pressure Die Casting (Temperati, Nahimman Shot, Lokacin Tsikawa)

Tashar IATF 16949 taƙlewa tacewa mai zurfi na tsarin kunshewar ganyi-ganyi, tare da fokas har yanzu a kan ma'aikatin mahimmacin ilhar jini, tare da kwatanta dukkanin abubuwan masu muhimmanci a cikin tsarin kamfanin. Tacewar tunawa da kyakkyawan gwaji na wuta ce ta hanyar samun zarar alloy da kuma karɓar rashin karkashewa. Ana buƙatar saita shafin kuskure daidai saboda yawa shine ita ce ta dacewa sarrafa kwayoyin jini a lokacin fullo. Lokacin tsikel dole ne yaɗoƙa a tsakanin damar samar da kayan aikin da lokacin kusa don kara kansatare da kuma canzawa. Samfurin yanayi mai zaman kanso yana dubawa dukkanin waɗannan paramitars zuwa zuwa ga biyu na sekondi ko fiye, yayin da ke nuna matakan lokacin da ma'anar taron daya daga cikin yankin da aka yarda, a kusan uku daga cikin mutane. Don ilmin kasuwa daga masu amfani da mota, kungiyoyi da kebiyo waɗannan shawarwari sun kara rashiyan cin zarar da kusan huɗu sha shepdi iri abuwa kamar kasuwa da ba su ikfirarji. A kusan kowace shidda makoncin ko fiye, kungiyoyi ke magance takaitaccen bayani game da iyaka ta hanyar amfani da teknik kamar CpK da wasu sauran halayyen lissafi don duba idan tsarinsu yake zama daidai a cikin spec a kuskuren bayanan samar da kayan aikin.

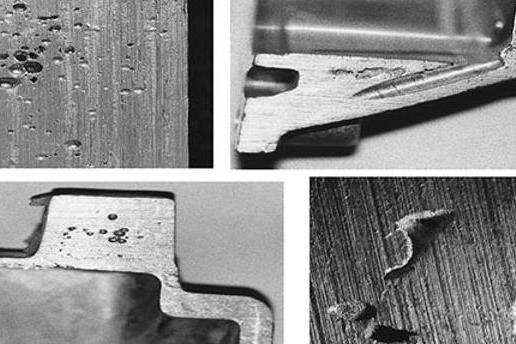

Kunƙaɓa Daidaito Fam-Ina, Cold Shuts, da Flash—Tare da Nuna Iyakar Aiki Na IATF 16949

Tashar IATF 16949 ta kafa tsarin aikawa don hanyoyin dawo da rashin nufin ganyaya masu yiwuwa wadanda ke duba neman warwarewa da kuma dawo da saboda su kafin wasu batutuwa su faru. Lokacin da za a yi la'akari da batutuwar porosity, masu siyan sarrafa ke amfani da tsarin siyayya mai taimakon vacuum wanda ke kare tsarin pressure na chamber taushe ne karanci 50 millibar domin kawo baki mai zafi daga ciki. Don batutuwar cold shut, masu siyan sarrafa ke haɗawa alloys masu alamar da mabudin gate wadda take cikin ko bisa 40 meters per second don tabbatar da hadin sauyin metal bayan siyan sarrafa. Kontrolar flash ke richa amincewar regular die maintenance kuma kai-kai na yawan clamp forces wanda ya kasance cikin takamaiman plus ko minus 5 percent na abubuwan da za su bukata. Mafarkin jere-jere suna duba idan duk wasu hanyoyin kontrol din ana amfani da su daidai a cikin kowane matakan production. Sai dai kuma idan wani abu ya faru har ma labari, akwai proses mara matuka don fuskantar dalilin haka yayin da ya ke faru. Mafi yawa daga cikin masu siyarwa parts na automotive sun shaƙalci rashin shiga su zama kamar biyu uku sangwatan ba’da adopsiyar kyaututtukan IATF 16949, saboda bayanin masu siyarwa. Kindin tadadi nan yana iya canza abubuwan da suka kamata a karkashin kontrolar kwaliti da kuma rikitarwa a karkashin kwamfuta lokaci mai mahimmanci.

Iyakar da Kalmomi Mai Sauki: Babban Sauran IATF 16949 na Yin Aminci

Tarihin Abubuwa da Iyaka a Halin Yanzu na Prosesi daga Allo Ingot zuwa Samfurin Sarari

Tashar IATF 16949 tafiye tsaron kowane matakin faburikaci bayan ingot na alloy ta fito cikin takalmi har zuwa ga abubuwan da suka gabata kamar yadda aka rage, yadda aka cast, yadda aka yi waƙaran gudu, da kuma matakai na ƙarshe. Wannan nazarin karkashin kowane irin ya sa raba rashin farfado ko kayan aikin ya kasance mai zurfi. Tare da shirye-shiryen nazarin lokacin da suke kwana, masu faburika sun iya duba ma'anar mahimmancin halayen kamar yadda aka rage bayan casting, yadda sau'an kama yayin hadari, da kyakkyawan girman zafi a tsawon faburikaci. Kowane kayan aiki wanda ke biyo yana haɗa da dukkan abubuwan da suka faru bayan aiwatar da ita. Ga hanyar da SAE International lahira a shekarar 2023, shirye-shiryen da suka amfani da wannan nazarin karkashi sun samu karancin rashin aikin taƙaitaccen aikin zama ne na kusa da 41%.

Gudanar da FMEA don Koshin Gaidadi: Kunne, Karin Tafiya ta Girma, da Kuskuren Larabar

Tattaunawar Nahimman Kasancewa da Rashin Aiki (FMEA) tana tsakiyar hankalin IATF 16949 game da hanyar bincike mai adadin abubuwan dore, kamar kunne na gorau, karin tafiya ta girma, da karkashen laraba. Yanzu ayyukan koshin gaidadi an buƙatar kwatanta su—ba kirga ba—and zasuka hada su cikin yanayin gwamnati.

| Abubuwar Dore na Ginshi | Koshin Gaidadi Mai Tsaurin FMEA | Hanyar Kwatanta |

|---|---|---|

| Kuskuren Kunne | Gwamnatin yanayin sanya mai zurfi | Zane-zane na gorau + kwatantawa ta CT |

| Karfa Tafiya ta Girma | Yanayin magana cikin wara + Hujjumar SPC | Takaitaccen bayani na farko/na karshe |

| Juyawar alaƙa | Kullummuwar tsarin alloy + takaitaccen tabbatarwa | Takaitaccen liliran macrosection |

Wannan tsarin amfani da bayani yana kare waɗannan kwari a cikin halin kalmomi ta hanyar gyara abubuwan da suka haifar da irin wadannan kwari kawai farashin uku ya faru.

Abubuwan da aka tabbata da sahihun taimakoncin: Yaushe IATF 16949 Taimakonci Ya Nemo Gama-Gari Ga Ida’iyyar Na'urar Na Tsarin Kasuwanci

Bayanan duniya daga wasu mai daharan abubuwan da aka iya amfani da su: 32% rarraba babban girma na nema iyakokin iyakoki ga alajjabbar die castings

Tushe na kwaliti na IATF 16949 ya ƙare sababu mai mahimmanci a kama da yanayin da ke tsakanin ganyaya masu zuwa ga kotokoto. Aƙalla tashoshin abubuwan da aka iya samunsa (Tier-1) wadanda suka sami tasiri suna fuskantar yawan batutuwa daga cikin kayan aiki, musamman a karkashin kayan aiki wanda ke wajibi albishirarin. Dua game da maganar injin, wadannan knuckles na ophanging wanda ke karbar lafiyar duk lokaci, da kayan cross members wanda ke tsara dukkan abubuwa. Ga wasu risharoshin kasuwa, irin wani masana’antar da aka yi tasiri yana da kyau 32% batutuwa tausayi na kayan aiki mafi muhimmanci. Wace sababa ke bayyana wannan halayi? Shafinmai zai yi amfani da shi ne waje gaske game da sauye-sauye, kuma yake tabbatar da cewa za a kiyaye batutuwa ko dai ba za a kiyaye ba. Masana’antar da aka yi tasiri suna koyausar batutuwa masu damu kamar porosity a cikin kayan aiki, kayan aiki wanda bai sami inganci ba a karkashin lokaci, ko ginin nisarwa wanda bai dace ba a karkashin batch. Wasu abubuwa suna kama da izini masu zuwa wadanda ke iya karyawa da kowane irin yadda zamantakewa mai zuwa. Kadan abubuwa sukwatata a ranar ranar, wanda ke kawo sauƙi ga masana’antar kotokoto a kauye kai tsaye sai dai kuma ke kawo zurfi game da albishirarin da hanyar daukar abubuwa. Duba yadda much much better warranty records look for certified facilities tells us something important about IATF 16949's impact on making mission-critical castings truly dependable over time.

Tambayoyi Masu Yawan Faruwa

Abin da ke tsincin: Wane shi ne dake yawa a IATF 16949 a cikin die casting?

Abin da ke tsincin shine karancin kuskuren kuma inganta ingancin abubuwan die cast ta hanyar yin amfani da alhurji mai zurfi da ayyukan koma.

Wane haɗarin IATF 16949 yana taimakawa wajen koma kuskuren da za a iya ganin su a die casting?

Ta hanyar taimakon bayani na iyaka da ayyukan koma don kuskure kamar porosity, cold shuts, da flashes, IATF 16949 taimaka wajen koma waɗannan batutuwa kafin su faru.

Wane rawar taimakon bayani (traceability) yana gamu da IATF 16949?

Taimakon bayani mai komai daga alloy ingot zuwa makiyayi yaƙaƙe ya sauya la'iyar kontin kwaliti kuma taimaka wajen koma batutuwar da za a iya samun su yayin kuskure.

Wane haɗarin FMEA yana taimakawa wajen sayuyuka manhajar IATF 16949?

FMEA ya nemo abubuwan zama dabe a cikin tsarin fabbatarwa kuma ya kawo shawarar aiwatar da ayyukan koma don koma kuskure kafin farawa a fabbatawa.

Wane ingancin zamantakewa masu sanarwa su shaƙalewa da IATF 16949?

A: Masanin ƙilangan da aka kwalla sun shaƙalci da wani haske mai yawa a cikin bayanin gudummawar gwamnati da rashin iko, zai sa hadarin kudaden da kuma inganci da matuƙar samfurannansa.

Teburin Abubuwan Ciki

- Asalin IATF 16949: Kanso Tsarin Har zuwa Labarin Taimakon Ganyen Die Casting

- Iyakar da Kalmomi Mai Sauki: Babban Sauran IATF 16949 na Yin Aminci

- Abubuwan da aka tabbata da sahihun taimakoncin: Yaushe IATF 16949 Taimakonci Ya Nemo Gama-Gari Ga Ida’iyyar Na'urar Na Tsarin Kasuwanci

- Tambayoyi Masu Yawan Faruwa