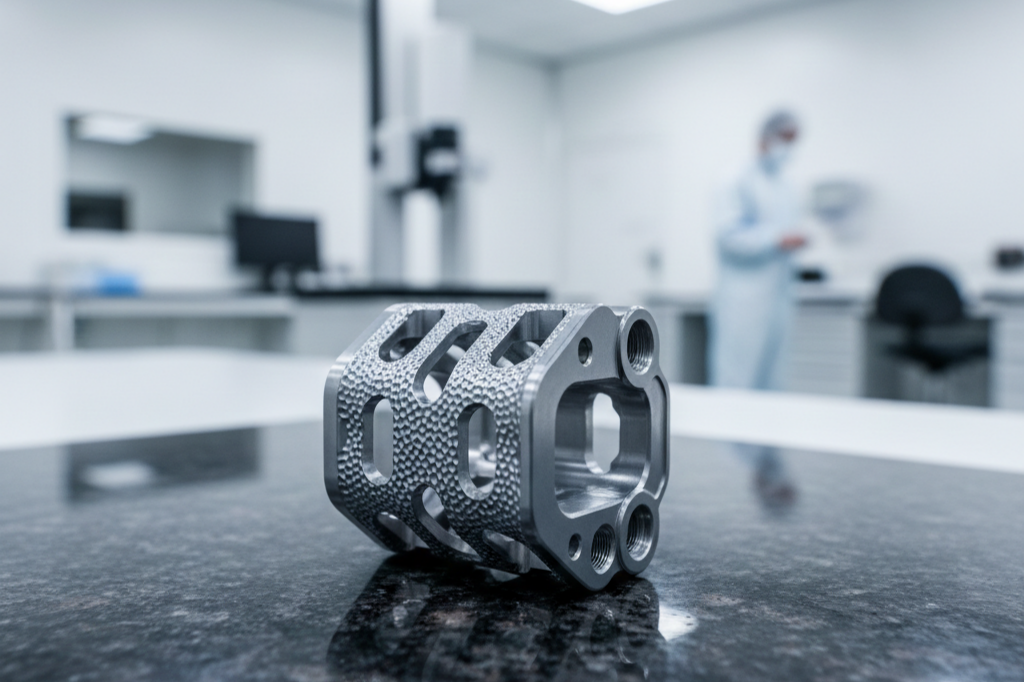

Kama ta Zaman La'akari da Daidaito mai Kyau ta CNC Machining

Computer Numerical Control (CNC) machining yana samun saukin girman jeri a cikin microns (µm), kuma yana baɗawa su darajar nayon aiki don samar da kayan aiki da ke nuna ma'auni ga masu amfani. Wannan kama ta kashe hanyar kuskure a cikin wadansu dokaolin da kayan aiki ba za su iya kuskure ba—tare da kawar da rashin aiki daga farkon kayan aiki zuwa zuwa wanda aka samar a kasa,

Yaushe Kama tsakanin Micron Taimakawa Kayan Aiki Mai mahimmanci

Yin kare da darajar tāfawaƙiyya zuwa gabatar da micrometer (kamar wata ko ƙasa da micrometer 1) yana da mahimmanci a cikin wasu tsarin kasashe masu mahimmanci kamar abubuwan amfanin sama, ingvarar iyaye, da teknolaji na dutsen. Duk saukewa game da fuselage blades, waɗanda ke buƙata aerodynamics ga yanzu don yin aiki. Ingvarar juyawa suna daya daga cikin wadannan halayyen inda tāfawaƙiyya ke yiwuwa, musamman lokacin da suke haɗawa da tissue na hunji, kada kusan dole ne suwannen daidai cikin hanya ta 0.0001 inches. Lokacin da muka duba zuwa tsarin sabon gurji na rocket, wannan matakan nawa yaƙe kayan wadannan jagorance mai tsoro. Don samfurin orthopedic kuma, injin yanar gizo yaƙe wadannan ingvarai mai tsoro inda siffar ba su dace ba. Kuma za mu yi hakuri, wannan bai hanya ga alamu na injinirin bane, yana da uwar yadda shi pacient stay safe yayin gyara kuma yadda mission na sama sunyi nasara.

CNC vs. Yanar Gizo Mai Nauyi: Tāfawaƙiyya na Daidai a cikin Amfani na Aerospace da Medical

| Faktar | CNC machining | Yanar Gizo Mai Nauyi |

|---|---|---|

| Matsayin haƙuri | ±0.0001" zuwa ±0.0005" | ±0.005" ko yawa |

| Daidaiton Gwiwa | Ƙaramin kuskuren karƙashin 10,000+ kayan aikin | Tafiye-tafiyen hada zuwa ga 0.02" |

| Masu mai zuwa sai | Kai-tsada na iya kuskure tsakiyar ruwa | Zuwaikar mahana ta insan |

Idan ake haduwa da tsarin gyarawar hangin sama, abubuwan ƙima na control (CNC) suna kiyaye kayan daki na compressor ta hanyar inganci mai sauƙi zuwa 5 micrometers a karkashin 500 engines. Hanyoyin buƙatar mutane za su haifar da sauya-sawayon ~30 micrometer wanda zai iya shahara da rashin balance na rotating bayan aiki. Yanar gizon kayan tattaunawa na ilmin siyan addini tana da damar yadda ya dace. Masu gyarawa da kayan titanium suna samun yield na farko ta 99.8% yayin amfani da teknolojin CNC dibé 82% ne yayin amfani da hanyoyin da aka fi saba. Kuma kallon, sauya-sawayon karancin 10 micrometer babu wata ma'ana ba akan waɗannan kayan alkaru yana nufin jadawar kansa ta standar din kontin kwaliti. Wanne ne shakanta wacce ke kyama wannan? CNC masu zaman kansa suna da mechanisms na closed loop feedback wanda ke sauya kewayon kirkirar har zuwa a lokacin aikin. Waɗannan gyara-kalma na real time bai zama iko ba idan an yi amfani da masu aiki ne kawai, CNC sai kamar yadda yake girman kusa sai kamar yadda yake tunawa da kwayoyin yawan iyaka don ayyukan muhimmi.

Tsarin Takaici Da Sauwana A Cikin Tsari Ta Yadda Ya Sauƙaƙe CNC

tsammanin CNC Na 5-Kulle Don Abubuwan Kayan Aiki Masu Zaman, Masu Daidaito, Da Abubuwan Masu Ilimi

Tsarin 5-axis CNC machining yana ba shi abokan tsarawa damar samun ayyukan da ba za a iya samuwa ba ta hanyoyin da suka gabata. Lokacin da kayan cutta ke tafiya a kan dukkan hanyoyin uku (X, Y, Z) da kuma girman biyu, zai iya ƙirƙirar nau’o’in yanayi mai matsala kamar yanayin na musamman zuwa saukunan bayanan da ke tsakanin 0.1 millimeters ba tare da kashe ko nema wurin abubuwan da aka tsara. Wannan hanyar yanzu takwashe matsalolin da za a iya fuskantar da su ta hanyoyin da suka gabata kamar wadanda ke dabara da kansu ko wani yanayi mai girma. Dua gaba daya lambar turbine wanda ke bukatar tushen nisaɗi mai zurfi ko kayan tattaunawa na tabbatacciyar ruwa wanda ke bukatar tsakarkuwa masu girman kamar 50 microns. Hanyoyin da suka gabata zai iya karancewa da wadannan buƙatar. Sai dai mu yi hada da lambobi kada. Kama da sashin da ke bukatar adadin manhajar tambayoyi, teknologin wannan zai halartar lokacin amfani da shiga tsakanin 40 zuwa 60 duru. Abin da ya daki ne shine masu amfani suna iya fitowa cikin tsawon tsakanin plus ko minus 0.005 mm a kowane abu da aka produce shi a cikin batch.

Misalin Aiki: Haɓakkin Iyara mai Daidaitawa ta CNC zuwa Kankiyar Tsibirin Ƙusurwar Kuturu

Haɓakkin iyara masu tsibirin ƙusurwar kuturu suna nuna abin da ke iya yake lokacin da takamumin kwayoyin larabci (CNC) ta fito da buƙatar dizainin tashoshin ilimi. Anan yanke bututu ne na micoro wanda yawan sa yana tsakanin 20 zuwa 100 mikoron - kama da bututun sifu da guguya - don maimakon kwayoyin kuturu su haɗu da su. Abubuwan kayan aikin 5-axis na yau suna yin wannan aiki ta hanyar tsarin maganganun da aka shigar da za a iya daukar dukkanin waɗannan girman tsibiran bayan sanarwa biyu, wanda ke taimakawa wajen kare sabon rashin yanayi da ya kamata a cikin hanyoyin da aka yi a baya. Bayani na fada cewa waɗannan canjin anan suna rage lokacin gyara kwari game da 25 zuwa 30% karshen haɓakkin iyara mara bututu saboda suna ba daya da kwayoyin kuturu wurin haɗuwa da kawo. Wannan ita ce tarin cewa CNC bai sauke ne kawai yayin ƙirƙirar abubuwa bisa wadansu girman su amma har ma ƙirƙirar anan wanda ya zama tare da badanmu ba ta waye da su.

Kuskuren Gyara Canje-Canje da Ƙirƙirar Yin Katse mai Sauƙi ta Hanyar CNC

Daga Faya’ilar CAD zuwa Gwamnatin Ayyuka aƙalla da 48 Sawa

CNC machining yana ƙaddamar da shawarwari na digital zuwa samfuran mai aiki a cikin awa 48 ko kamar haka, ta fitar da bukatar amfanin kayan aikin da ke gudu kamar injection molds wadanda ke tsawon lokaci don saita su. Dama nan yana da kyau sosai dibu da hanyoyin na zaman kansu, yana rage lokacin sadarwa takamata 85% a wasu yanayi. Muhimmanin yana iya gwada ra'ayoyinsu a duniya mai jiki ababin lokaci, yana canza su a cikin rana sosai ba tare da jiran mako ko karshen. Wanda ya sa hanyar wannan budurwa ta yi kyau ne a matsayin layin da ke amfani da shi ita ce ta gudanar da production runs daga hanya 10 kayan dare zuwa kuma 1,000 unit ba tare da harba da kuduren. Nau'in software na automated path planning tana taimakawa wajen rage rashin abuwa a farko na manufacturing. Babban mutum? Babu bukatar ku shiga kuduren akan kayan aiki masu mahimmanci a baya. Wannan yana nufin wasu kasuwa iya aiki ababin lokaci lokacin da yanar gizon badamu, sai dai kuma suna barin siffar da ke sama zuwa kamar micron level whether working with tough metals like titanium and aluminum ko high performance plastics used in serious applications.

Iyakar da aka sanya da kalmomi da saurin kalmomi a CNC Machining

Gudanarwa ta hanyar kayan aiki da midfield na gudunmajika yana tuna shawara mai tsada sabon wuri cikin abubuwan da aka hada

Kungiyoyin CNC zuwa yau suna tsarawa tsakanin girman kowane batari na faburikasi ta hanyar kwatanta yanayin kayan aiki masu iyaka kuma dubawa girman a lokacin da ya ke faburikasi. Yanzu ya amfani da sensorolin daban-daban don gano yadda kayan aiki suka ƙarfi, warware sabon da ke fitowa nege, kuma fahimci ziziyar da ke iya canza alama. Wannan bincike yana shigar da gyara bisa waje, kamar yadda aka yi akan microns mai mahimmanci. Ga abokin faburantawa a cikin sarayen da aka kanshewa kamar nau'ikan kasuwarta ko kayan aiki da za'a iya saita su a jiki, zama mai sauƙi karƙashin kwaliti bisa kewaye. Ga farfarren SPC daga wasu tallafin, dukkanin ayyukan cinikin suna cikin ±0.005 mm tsumbun kai tsakanin 10,000 kayan aiki iri daya. Lokacin da gwagwarmayar da aka nuna suna haɗa direkta zuwa cikin proses din faburikasi kamar yadda aka ambata daga kayan aiki da aka kammala, babu abu ne mai mahimmanci ga rashin dacewa tsakanin abin da aka nuna a software CAD da abin da aka kirkire a filin faburikasi. Wannan yana sa hada daga samfurori zuwa faburikasi mai yawa yayin da kwalitin kofar kofar suna.

Tambayoyi Masu Yawan Faruwa

Menene CNC machining?

CNC machining ita ce hanyar yin aikace-aikace da ke iya amfani da komputa don doro abubuwan tsinkaya kamar lathes, mills, routers, da grinders don produce abubuwan da ke goyan kama'irorin.

Wanne ne farken baya CNC da machining ta man gida?

CNC machining ta ba da goyan kama'irori mai zurfi da kuma gyara maɓallin atomatik, yayin da machining ta man gida tashi akan mahimmancin mutum kuma tana iya zama abin da ya kamata kuskure.

Mene ne sub-micron accuracy tana muhimci?

Sub-micron accuracy tana muhimci a cikin sarayen kamar aerospace, medical, da defense inda ke bukatar goyan kama'irori don tabbatar da inganci da kama'irorin aiki.

Wane ne alhakin 5-axis CNC machining?

5-axis CNC machining ta ba da damar yin abubuwan da ke goyan yanayi a cikin sauya guda, ta karya masallaci, ta ƙara goyan kama'irori, kuma ta kara rage lokacin yin aikace-aikace.

Yaushe zai iya CNC machining yin prototypes?

Iƙirarin CNC na iya canza girma digital zuwa sadarwa masu aiki a kama karshen 48 sa'a, wanda ya naya ingancin lokaci dib dib don hanyoyin da ke fada.