Unmatched Precision and Tight Tolerances with CNC Machining

Computer Numerical Control (CNC) machining achieves dimensional accuracies within microns (µm), enabling custom parts that meet exact specifications for mission-critical applications. This precision eliminates performance risks in high-stakes environments—where component failure isn’t an option—by ensuring functional reliability from the first part to the ten-thousandth.

How Sub-Micron Accuracy Supports Mission-Critical Custom Parts

Getting down to sub-micron levels of precision (around or below 1 micrometer) matters a lot across several critical industries like aerospace components, medical implants, and defense technology. Take turbine blades for instance, these need near perfect aerodynamics to function properly. Spinal implants are another case where accuracy counts big time, especially when it comes to how they interface with bone tissue, sometimes needing to be spot on within just 0.0001 inches. When we look at rocket fuel systems, these tiny measurements actually stop dangerous leaks from happening. For orthopedic devices too, precise manufacturing stops those tiny fractures caused by surfaces not lining up correctly. And let's face it, this isn't just about engineering specs it directly affects whether patients stay safe during surgery and if space missions actually succeed.

CNC vs. Manual Machining: Tolerance Consistency in Aerospace and Medical Applications

| Factor | CNC Machining | Manual Machining |

|---|---|---|

| Tolerance Range | ±0.0001" to ±0.0005" | ±0.005" or higher |

| Batch Consistency | Near-zero deviation across 10,000+ units | Up to 0.02" variation |

| Error Sources | Automated compensation for thermal drift | Human measurement fatigue |

When it comes to aerospace manufacturing, computer numerical control (CNC) machines maintain compressor blade profiles at an astonishing 5 micrometers precision across over 500 engines. Manual techniques typically result in around 30 micrometer deviations which can lead to dangerous rotational imbalances during operation. The medical device sector sees similar benefits. Manufacturers working with titanium implants achieve first pass yields of about 99.8% using CNC technology compared to only 82% with traditional methods. And remember, even a tiny 10 micrometer misalignment in these delicate parts means automatic rejection by quality control standards. What makes this possible? Modern CNC systems incorporate closed loop feedback mechanisms that continuously adjust tool paths as they work. These real time corrections simply aren't feasible when relying solely on human operators, making CNC not just faster but fundamentally more reliable for critical applications.

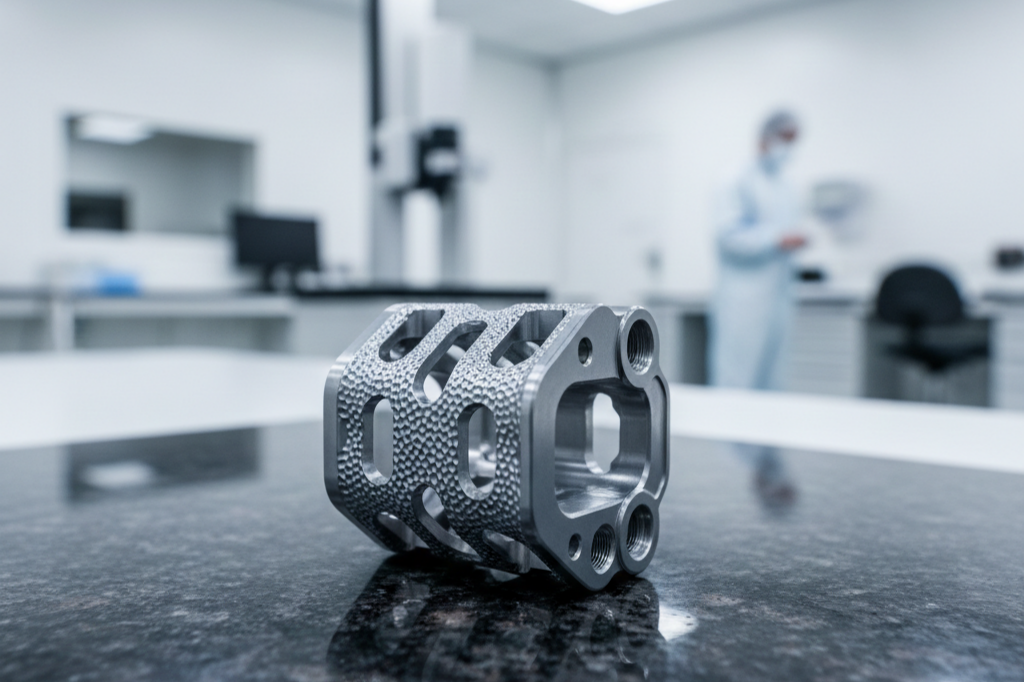

Complex Geometries and Design Freedom Enabled by CNC Machining

5-Axis CNC Capabilities for Organic, Asymmetric, and Micro-Featured Custom Parts

The 5-axis CNC machining process gives designers access to capabilities that just aren't possible with older techniques. When the cutting tool moves along those five axes at once X, Y, Z plus two rotations it can create all sorts of complex forms from irregular curves to tiny details as small as 0.1 millimeters without having to stop and reposition the workpiece. This approach basically gets rid of those pesky alignment issues that happen with undercuts and other tricky curved areas. Think about turbine blades needing intricate internal cooling passages or medical implants where bone scaffolding requires pores around 50 microns in size. Traditional methods would struggle with these requirements. And let's talk numbers for a second. Compared to setups that require multiple positioning steps, this technology typically reduces manufacturing time by somewhere between 40 and 60 percent. What's really impressive is that manufacturers still manage to hit tolerances within plus or minus 0.005 mm on every single item produced in a batch.

Real-World Example: CNC-Machined Titanium Spinal Implants with Surface Micro-Textures

Spinal implants made from titanium show what's possible when computer numerical control (CNC) technology meets medical design needs. The surfaces need special micro textures around 20 to 100 microns in size - think tiny ridges and pores - to help bones grow into them properly. Modern 5-axis machines handle this job with programmed tool paths that can texture all those curves without needing multiple setups, which helps prevent heat damage problems seen in older methods. Research actually shows these textured surfaces speed up recovery times about 25 to 30 percent compared to plain implants because they give cells better places to stick and grow. This proves that CNC isn't just about making things the right size anymore but also creating surfaces that work with our bodies rather than against them.

Rapid Customization and Efficient Low-Volume Production via CNC Machining

From CAD File to Functional Prototype in Under 48 Hours

CNC machining turns digital designs into working prototypes within 48 hours or so, skipping the need for expensive tooling like injection molds that take forever to set up. The speed advantage is massive compared to traditional approaches, cutting lead times around 85% in many cases. Engineers can test their ideas in the real world much faster now, making changes in days instead of waiting weeks for results. What makes this approach work well economically is that it handles production runs from just 10 pieces all the way up to 1,000 units without breaking the bank. Automated path planning software helps reduce waste during manufacturing. Best part? There's no need to spend money on special tools upfront. This means factories can react quickly when markets change, yet still maintain incredible precision down to the micron level whether working with tough metals like titanium and aluminum or high performance plastics used in serious applications.

Scalable Repeatability and Batch-to-Batch Consistency in CNC Machining

Automated Toolpath Validation and In-Process Metrology Ensure Zero Drift Across Production Runs

Today's CNC machining centers keep dimensional consistency throughout entire production batches by validating toolpaths automatically and checking dimensions during actual manufacturing. The system uses various sensors to track how tools wear down over time, account for heat expansion effects, and detect vibrations that might affect precision. These readings trigger adjustments on the fly, often within just a few microns. For manufacturers in highly regulated fields such as aircraft components or implantable medical devices, maintaining consistent quality across large volumes becomes much easier. According to SPC reports from several plants, most operations stay well within ±0.005 mm tolerance even when producing 10,000 identical parts. When digital designs get integrated directly into the manufacturing process alongside actual measurements taken from finished products, there's far less risk of discrepancies between what was planned in CAD software and what gets produced on the shop floor. This makes scaling up from prototypes to mass production much smoother while keeping quality standards intact.

FAQ

What is CNC machining?

CNC machining is a manufacturing process that involves the use of computers to control machine tools such as lathes, mills, routers, and grinders to produce precision parts.

What is the difference between CNC and manual machining?

CNC machining offers greater precision with tighter tolerances and automated corrections, whereas manual machining depends heavily on human skill and is prone to more errors.

Why is sub-micron accuracy important?

Sub-micron accuracy is crucial in industries like aerospace, medical, and defense where precise measurements are necessary to ensure safety and performance reliability.

What are the benefits of 5-axis CNC machining?

5-axis CNC machining allows for the creation of complex geometries in a single setup, reducing alignment issues, enhancing precision, and significantly decreasing manufacturing time.

How fast can CNC machining produce prototypes?

CNC machining can convert digital designs into functional prototypes in less than 48 hours, significantly reducing lead times compared to traditional methods.