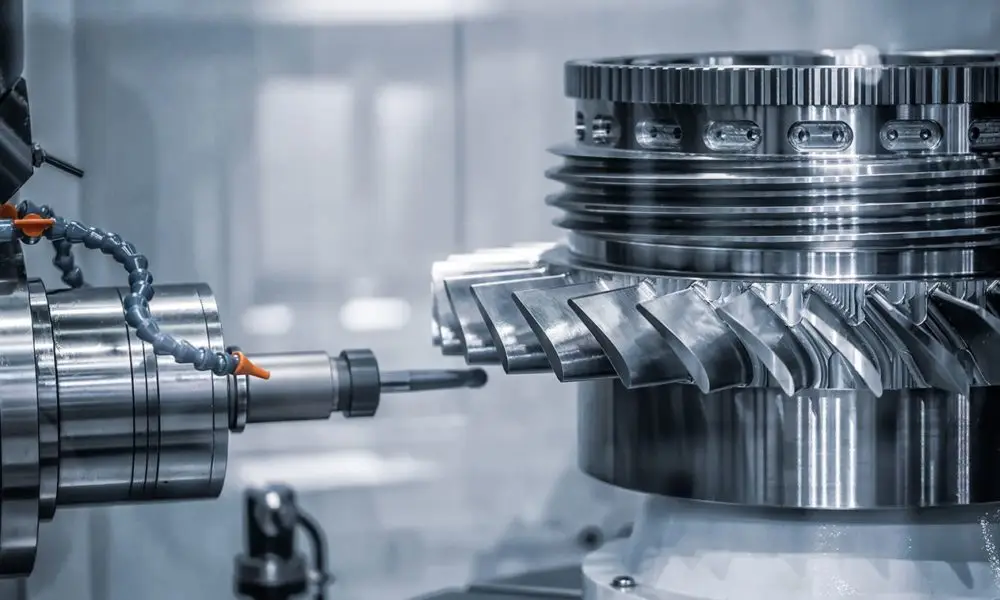

Sino Die Casting, founded in 2008 and based in Shenzhen, China, is a premier provider of CNC machining services for mold making, playing a critical role in the production of high-quality molds used across industries such as automotive, new energy, robotics, and telecommunications. As a high-tech enterprise integrating design, processing, and production, we understand that mold making is a precision-driven process where even minor inaccuracies can compromise the quality of thousands of finished parts. Our expertise in CNC machining for mold making ensures that the molds we produce are durable, accurate, and optimized for efficient manufacturing, making us a trusted partner for clients worldwide. CNC machining is indispensable in modern mold making, as it enables the production of complex mold geometries with tight tolerances that would be impossible to achieve with traditional machining methods. Molds—whether for die casting, injection molding, or blow molding—require precise cavities, cores, cooling channels, and ejection systems to ensure that the finished parts meet exact specifications. Our CNC machining services for mold making utilize advanced multi-axis machining centers, which allow us to machine complex 3D features in a single setup, reducing errors and ensuring that all mold components align perfectly. This precision is critical for achieving consistent part quality in mass production, minimizing the need for post-processing and reducing overall manufacturing costs for our clients. One of the key strengths of our CNC machining for mold making is our ability to work with hard, wear-resistant materials such as tool steel, H13, and stainless steel, which are essential for molds that must withstand the high pressures, temperatures, and repetitive cycles of manufacturing processes. Machining these hard materials requires specialized equipment and expertise, and our CNC machines are equipped with high-power spindles, rigid frames, and advanced cutting tools designed for hard machining, allowing us to achieve precise cuts and smooth surface finishes even in tough alloys. Our technicians are trained in optimizing cutting parameters to balance efficiency with tool life, ensuring that the mold machining process is both cost-effective and accurate, with minimal tool wear that could compromise precision. Our ISO 9001 certification ensures that every aspect of our CNC machining for mold making adheres to strict quality control standards. We implement a comprehensive quality management system that covers material selection, machine calibration, in-process inspection, and final verification. We source high-quality mold materials from trusted suppliers, conducting rigorous incoming inspections to verify material properties such as hardness and microstructure, ensuring that they can withstand the demands of the intended manufacturing process. During machining, we use in-process measuring tools such as touch probes and laser scanners to monitor critical dimensions and make real-time adjustments, ensuring that parts remain within tight tolerances. After machining, each mold component undergoes thorough inspection using coordinate measuring machines (CMMs) and optical comparators to verify accuracy, surface finish, and geometric integrity, ensuring that the final mold meets the exact specifications of the part design. We offer integrated design and CNC machining services for mold making,