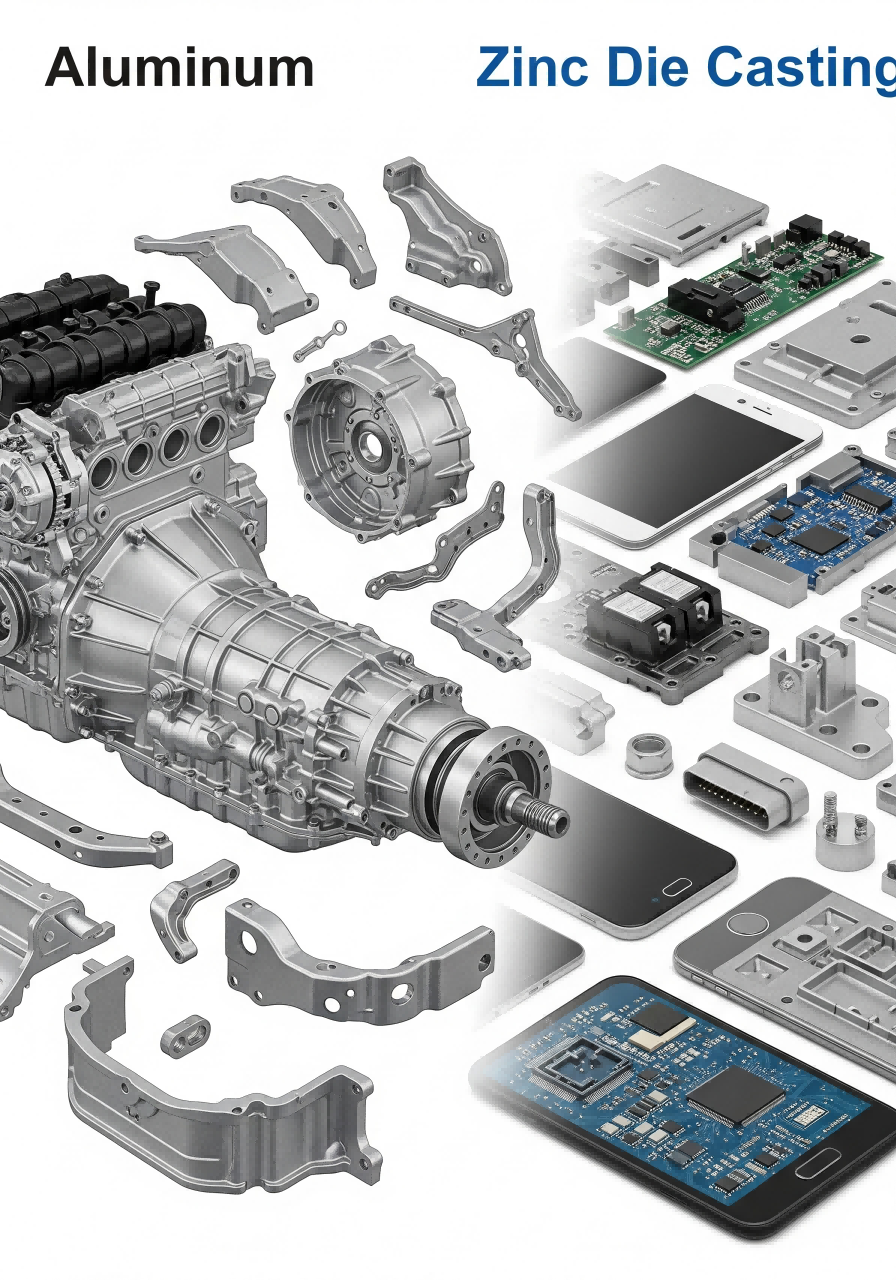

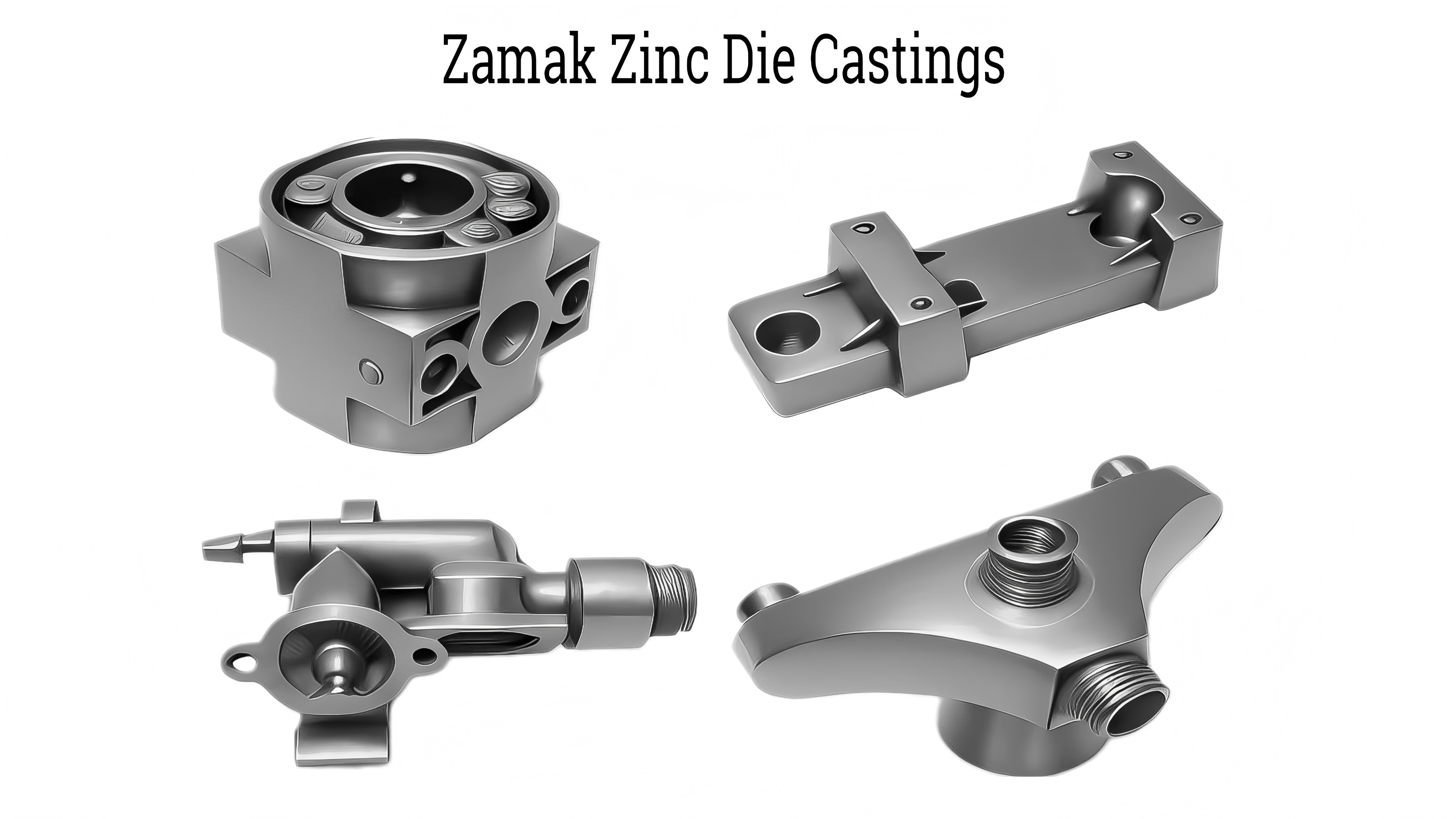

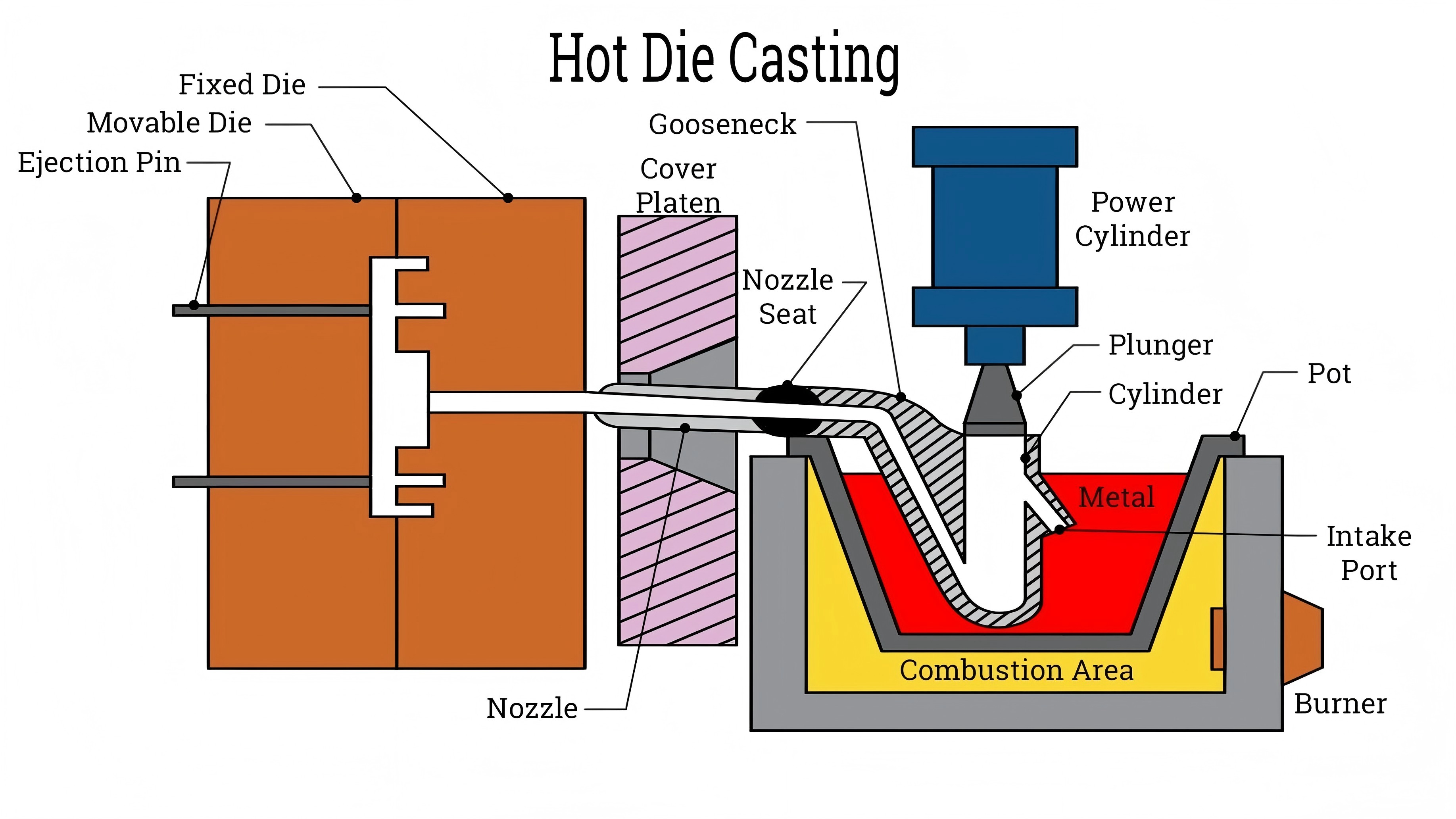

At Sino Die Casting, based in Shenzhen, China, our zinc die casting molds are crafted with precision and expertise, ensuring the highest quality in every component produced. As a high-tech enterprise established in 2008, we specialize in integrating design, processing, and production to deliver molds that meet the exacting standards of industries such as automotive, new energy, robotics, and telecommunications. Our zinc die casting molds are designed using advanced CAD/CAM software, allowing for intricate geometries and tight tolerances that are essential for high-performance applications. We employ state-of-the-art CNC machining centers to manufacture molds with exceptional durability and accuracy, ensuring consistent part quality over thousands of cycles. Our team of experienced engineers works closely with clients to understand their specific needs, providing customized solutions that optimize production efficiency and cost-effectiveness. With ISO 9001 certification, we adhere to rigorous quality control measures throughout the mold-making process, from initial design to final inspection. Our zinc die casting molds are engineered to withstand the high pressures and temperatures involved in the die casting process, ensuring longevity and minimal maintenance requirements. We also offer a range of surface treatment options to enhance mold performance and extend service life, including nitriding, chrome plating, and polishing. Whether you require simple or complex molds, Sino Die Casting has the capabilities to deliver solutions that meet your exact specifications. Our global reach and commitment to innovation make us a trusted partner for businesses seeking high-quality zinc die casting molds. By choosing Sino Die Casting, you gain access to a comprehensive service that spans from mold design to production, ensuring your zinc die cast parts are manufactured with precision and efficiency. We are dedicated to driving your business success through excellence in mold-making, providing you with the tools you need to stay competitive in today's fast-paced market.