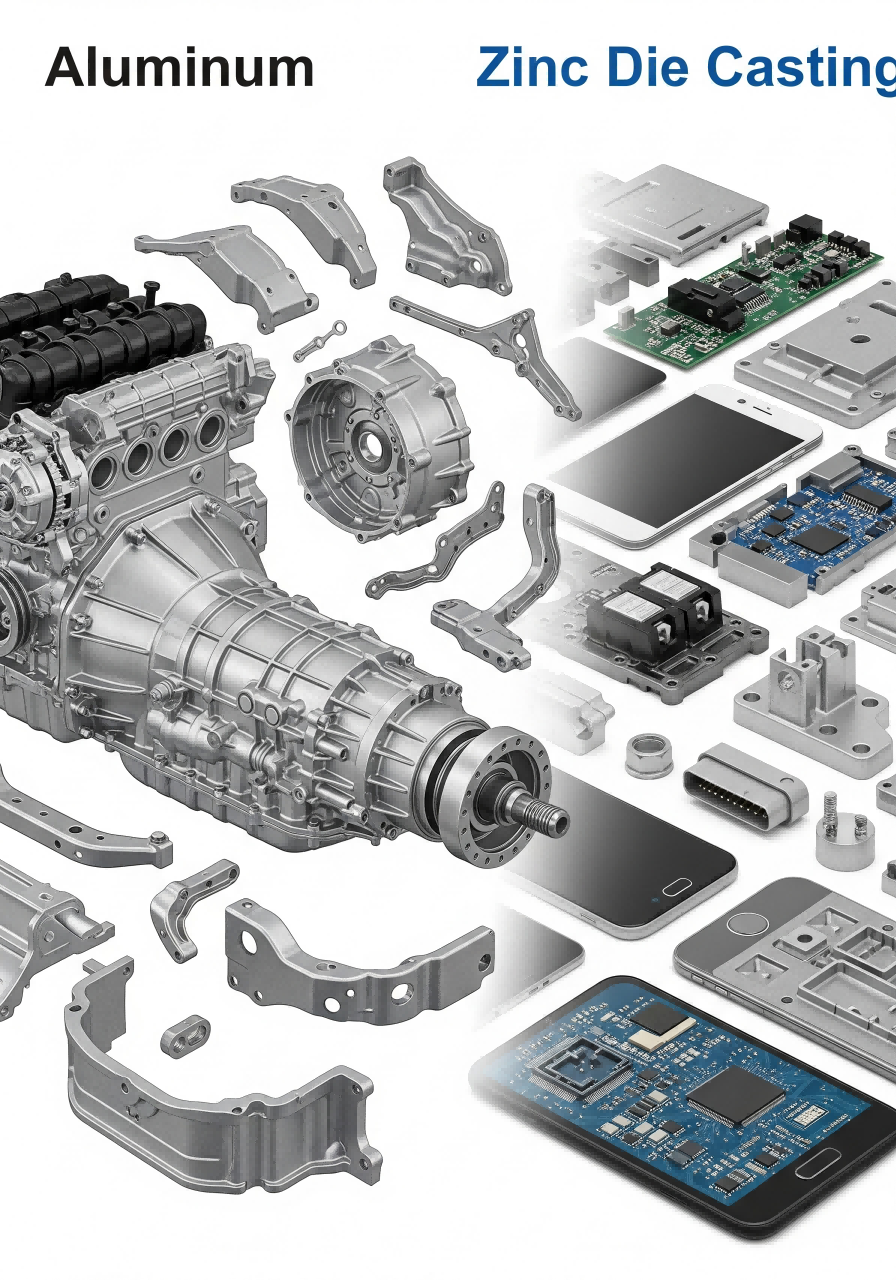

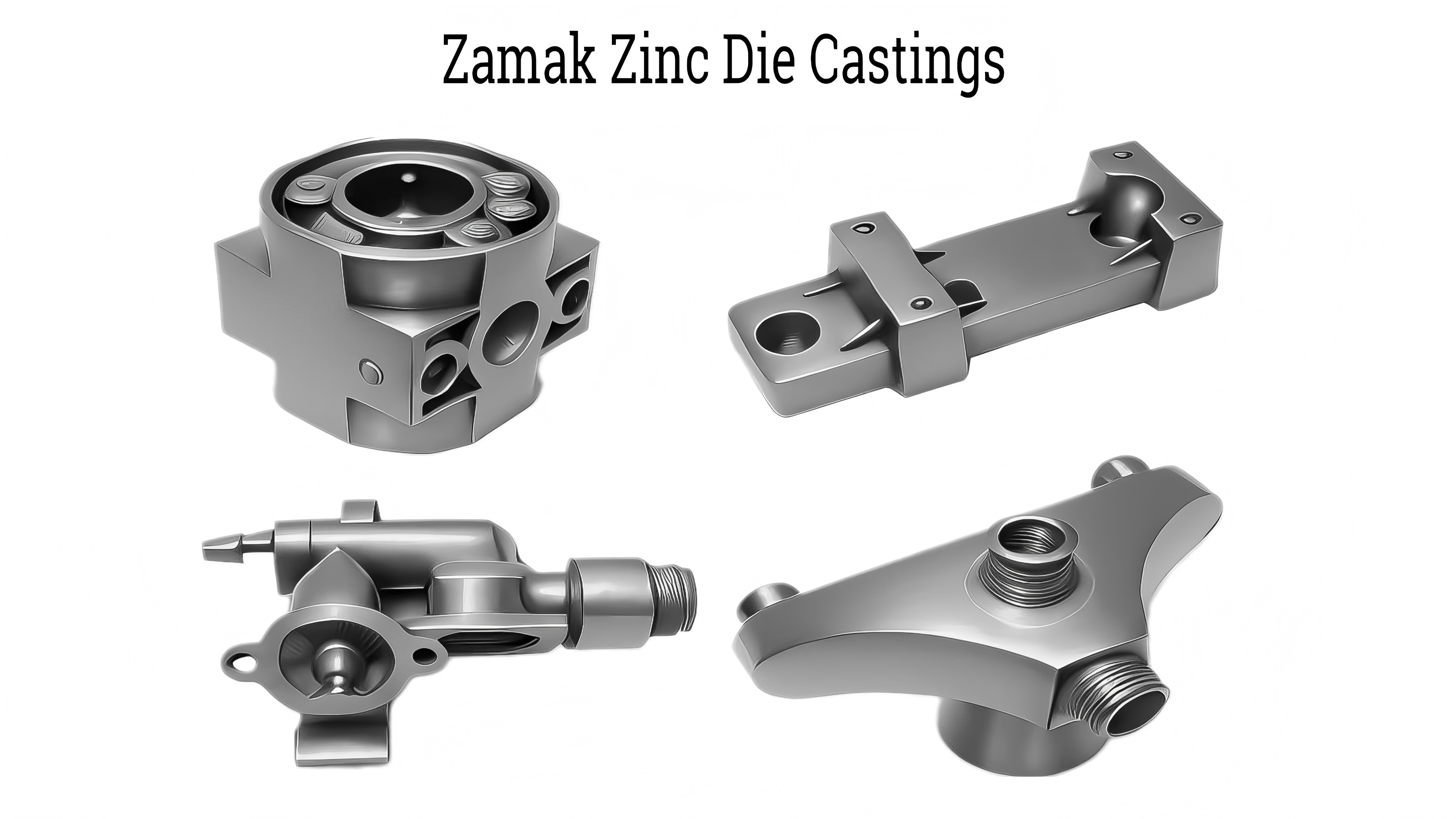

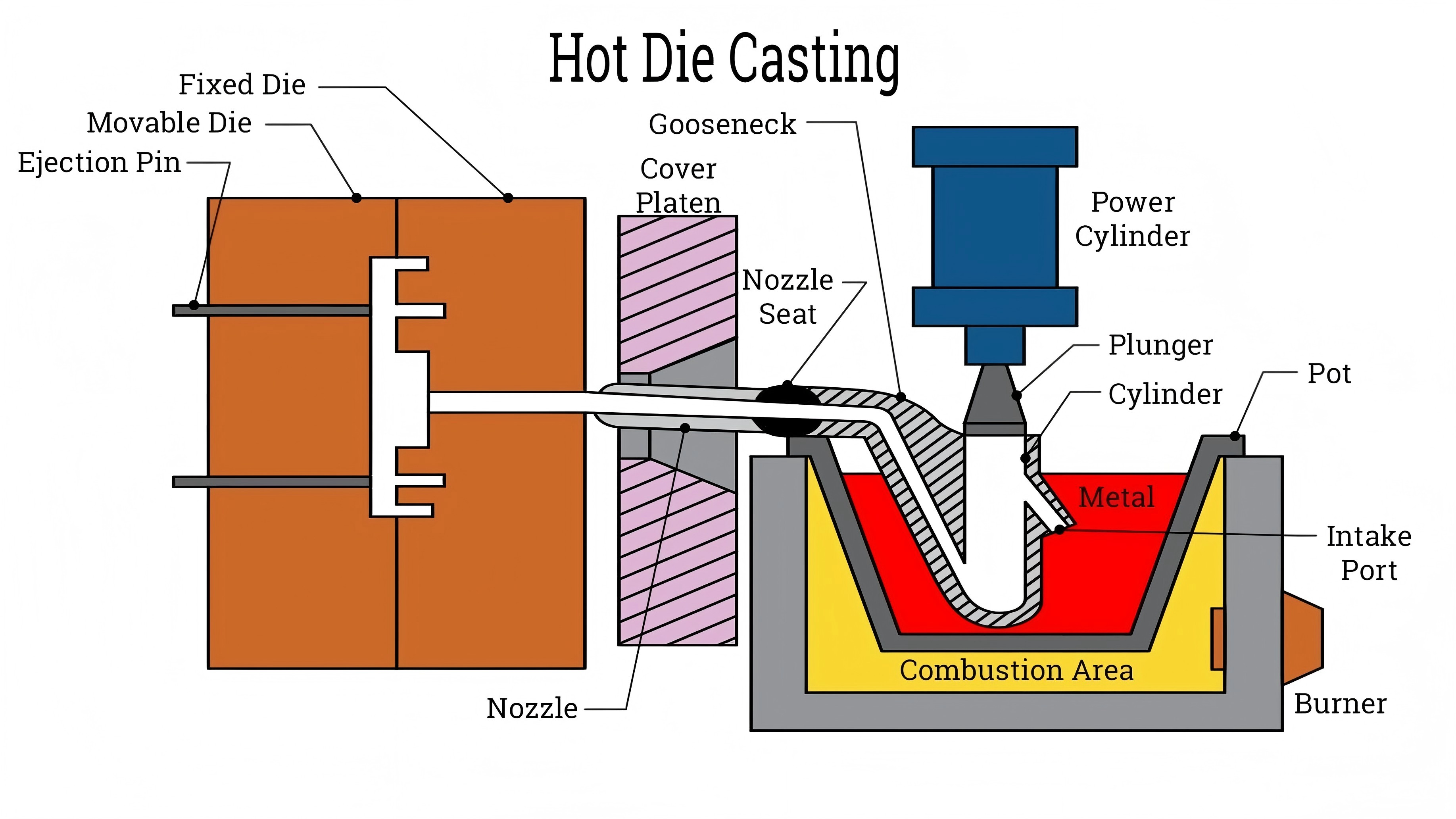

Sino Die Casting excels in zamak die casting, a specialized process that leverages the unique properties of zamak alloy to produce high-precision components for a wide range of industries. Based in Shenzhen, China, our high-tech enterprise integrates advanced design, processing, and production techniques to deliver zamak die cast parts that exceed expectations in quality and performance. Zamak, a zinc-based alloy with added aluminum, magnesium, and copper, offers excellent fluidity during casting, allowing for the production of complex shapes with fine details. Our zamak die casting process begins with the creation of precise molds using advanced CAD/CAM software and CNC machining centers. These molds are designed to withstand the high pressures and temperatures involved in die casting, ensuring longevity and consistent part quality. We utilize high-pressure injection techniques to fill the mold cavity with molten zamak alloy, producing parts with exceptional dimensional accuracy and surface finish. Our ISO 9001 certification guarantees that every zamak die cast part adheres to the highest quality standards, from initial design to final inspection. Our team of skilled engineers and technicians works closely with you to understand your specific requirements, providing customized solutions that optimize production efficiency and cost-effectiveness. Zamak die casting is ideal for applications where high strength, good dimensional stability, and resistance to corrosion are essential. Our zamak components are widely used in industries such as automotive, electronics, and telecommunications, where precision and reliability are paramount. We offer a range of secondary operations, including CNC machining, deburring, and surface treatment, to further enhance the functionality and appearance of your zamak die cast parts. By choosing Sino Die Casting for your zamak die casting needs, you gain a partner committed to your success, offering comprehensive services that drive innovation and efficiency. We are dedicated to providing you with the highest quality zamak die cast components, ensuring your products stand out in today's competitive market. Our global reach and commitment to excellence make us the ideal choice for all your zamak die casting requirements.