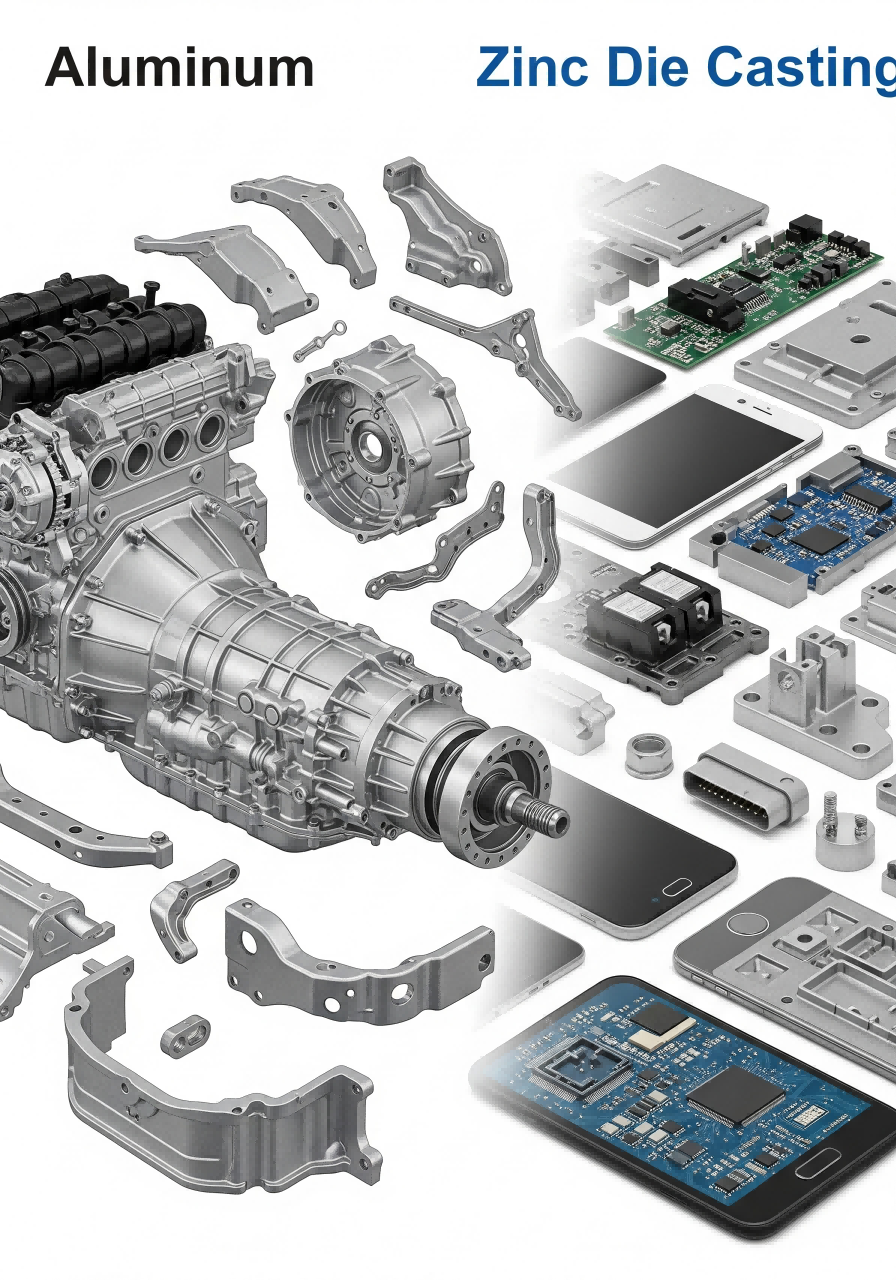

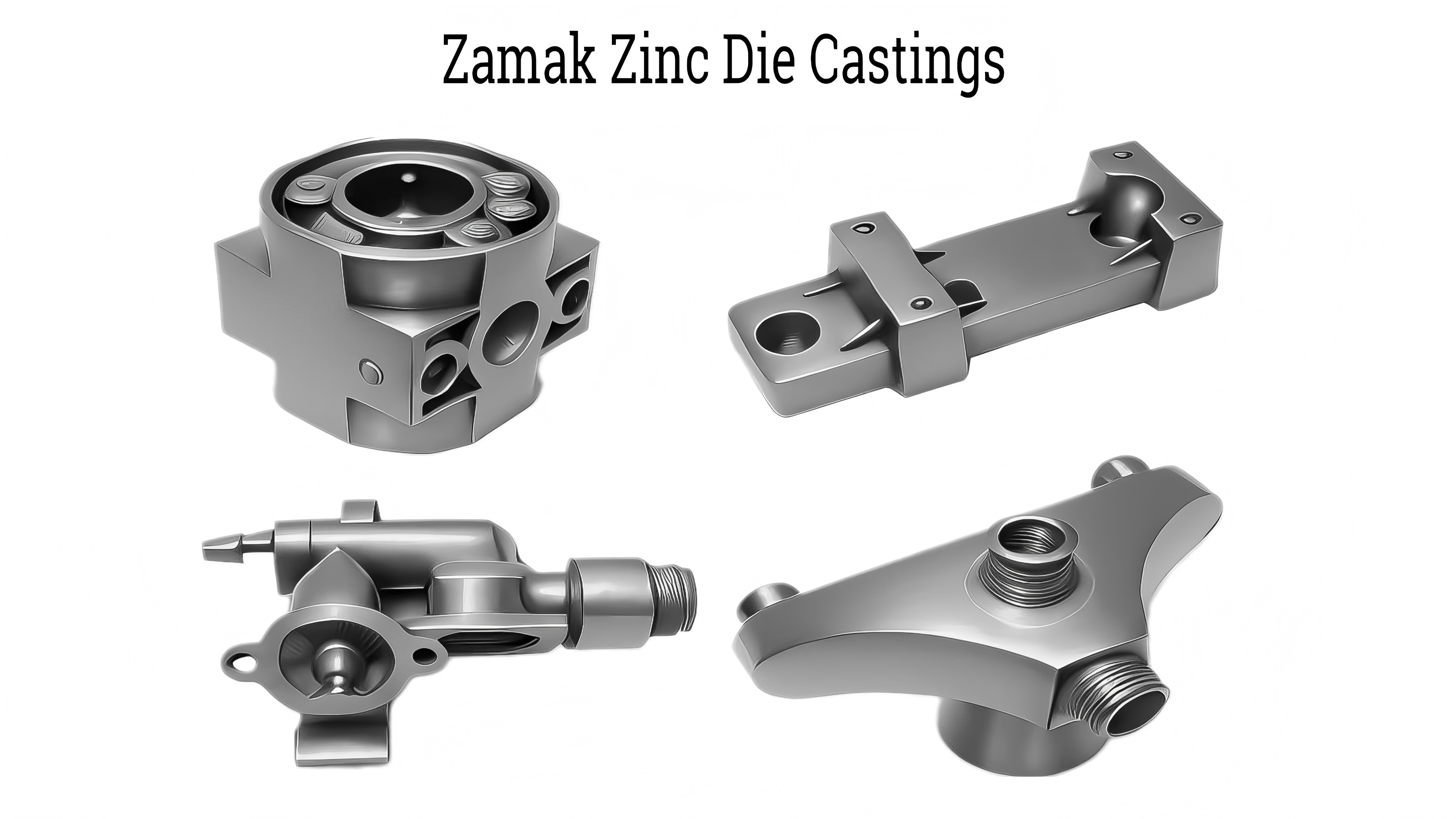

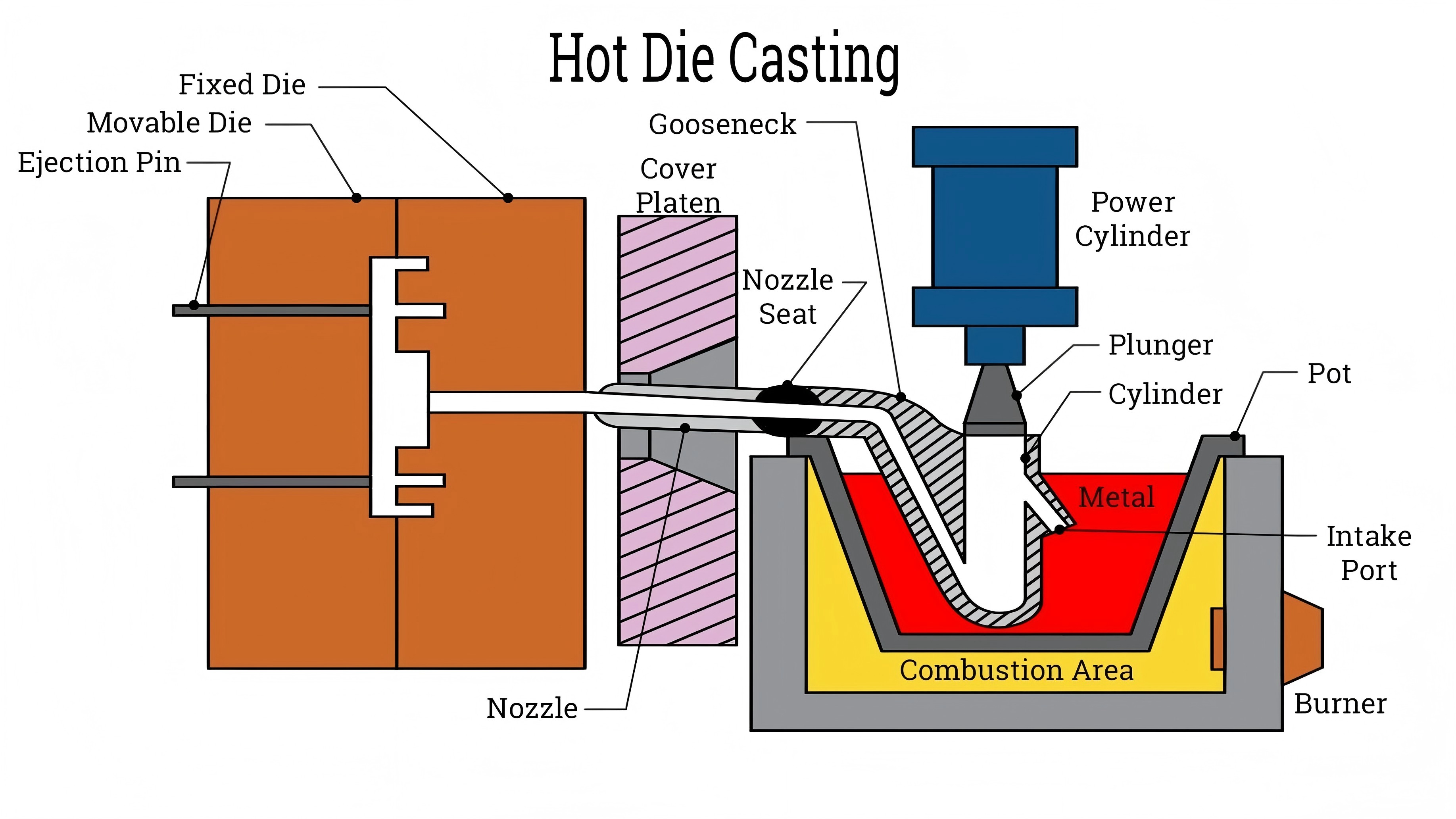

Zamak casting at Sino Die Casting, a high-tech enterprise based in Shenzhen, China, represents a pinnacle of precision and quality in the die casting industry. Zamak, an alloy primarily composed of zinc with small amounts of aluminum, magnesium, and copper, offers excellent casting properties, making it ideal for producing intricate and high-strength components. Our zamak casting process begins with meticulous mold design, utilizing advanced CAD/CAM software to create molds that capture every detail of your part's geometry. We employ state-of-the-art CNC machining centers to manufacture molds with exceptional durability and accuracy, ensuring consistent part quality over thousands of cycles. Our high-pressure die casting machines inject molten zamak alloy into the mold cavity under precise control, producing parts with tight tolerances and smooth surface finishes. As an ISO 9001 certified company, we adhere to rigorous quality control measures throughout the zamak casting process, from initial design to final inspection. Our team of experienced engineers and technicians works closely with you to optimize the casting process, reducing material waste and improving production efficiency. Zamak casting is widely used in industries such as automotive, electronics, and consumer goods, where high precision and durability are essential. Our zamak components are known for their excellent mechanical properties, including high strength, good dimensional stability, and resistance to corrosion. We offer a range of surface treatment options, including polishing, plating, and painting, to enhance the appearance and functionality of your zamak cast parts. By choosing Sino Die Casting for your zamak casting needs, you gain a partner dedicated to your success, offering comprehensive solutions that drive innovation and efficiency. We are committed to providing you with the highest quality zamak cast components, ensuring your products meet the demanding standards of today's market.