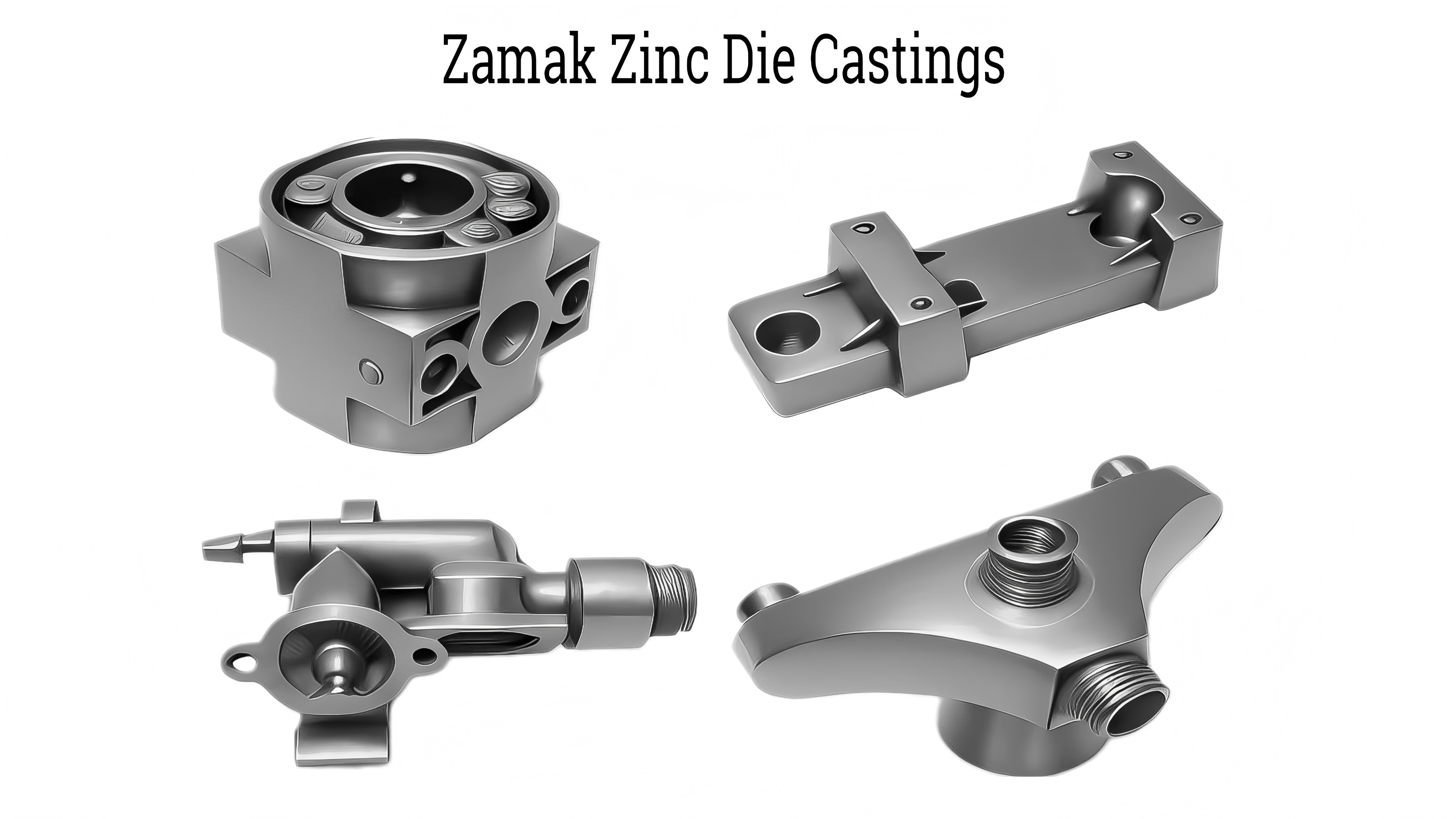

Sino Die Casting has been at the forefront of zinc die casting since 2008. Our location in Shenzhen, China, gives us access to a skilled workforce and advanced manufacturing infrastructure. Zinc die casting is a versatile manufacturing process that we use to create a wide variety of parts. In the new energy sector, we manufacture zinc die-cast components for photovoltaic inverters, wind turbine parts, and other energy-related equipment. These parts need to be highly precise and reliable, and our zinc die casting process ensures just that. We can produce parts with complex geometries and tight tolerances, which are essential for the efficient operation of new energy systems. Our zinc die casting machines range from 88 tonne to 1350 tonne, allowing us to handle projects of different scales. Whether you need a small batch of prototype parts or large-scale mass production, we have the capabilities to meet your demands. We also offer CNC machining services to further refine the zinc die-cast parts. This is especially useful for parts that require precise dimensions or specific surface finishes. Our team of engineers works closely with you throughout the zinc die casting process. From the initial design stage to the final product, we ensure that your requirements are met. We can provide design optimization suggestions to improve the manufacturability and cost-effectiveness of your zinc die-cast parts. With our comprehensive quality management system, every zinc die-cast part undergoes strict inspections. We use coordinate measuring instruments, image measuring instruments, and other testing equipment to verify the dimensions and functionality of the parts. By choosing Sino Die Casting for your zinc die casting needs, you get a partner that combines technological expertise with excellent customer service.