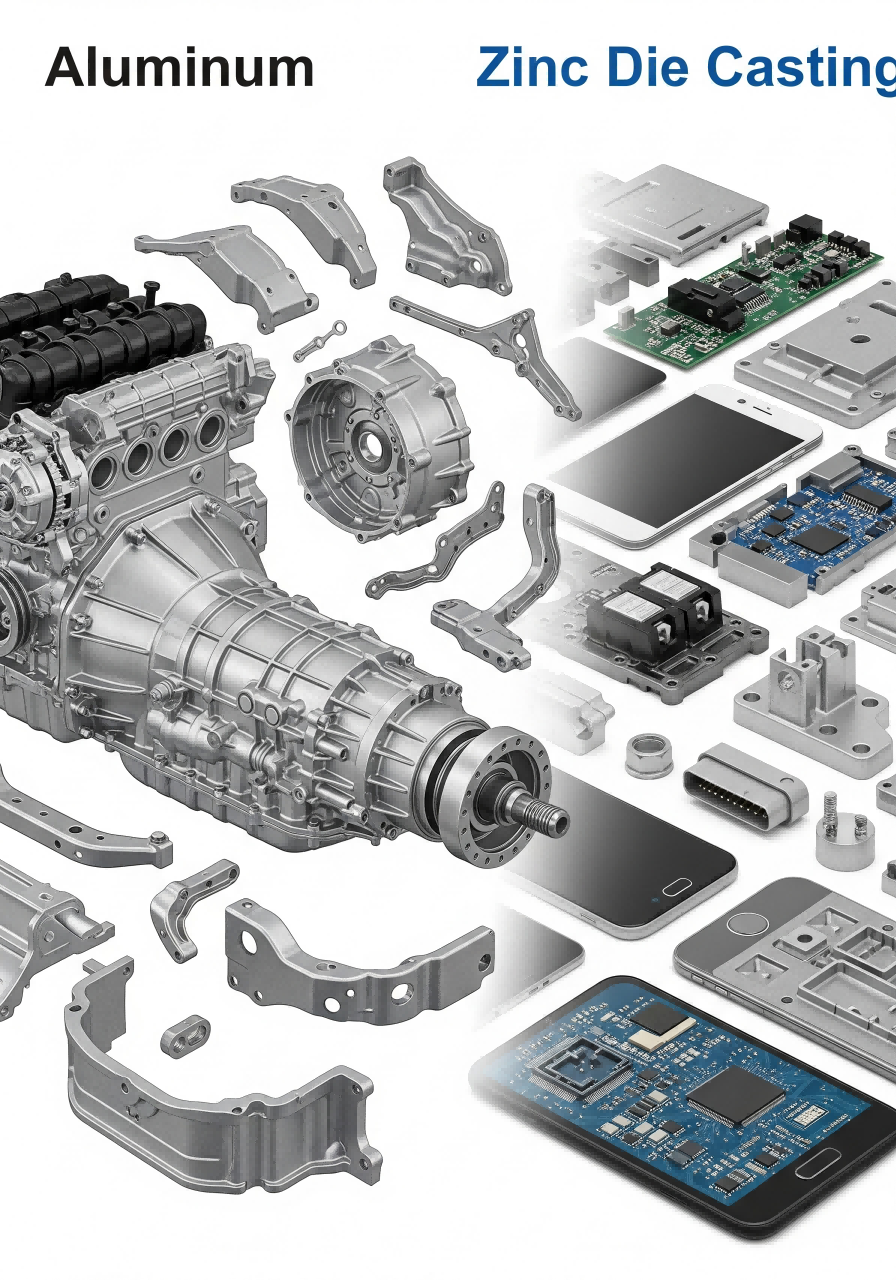

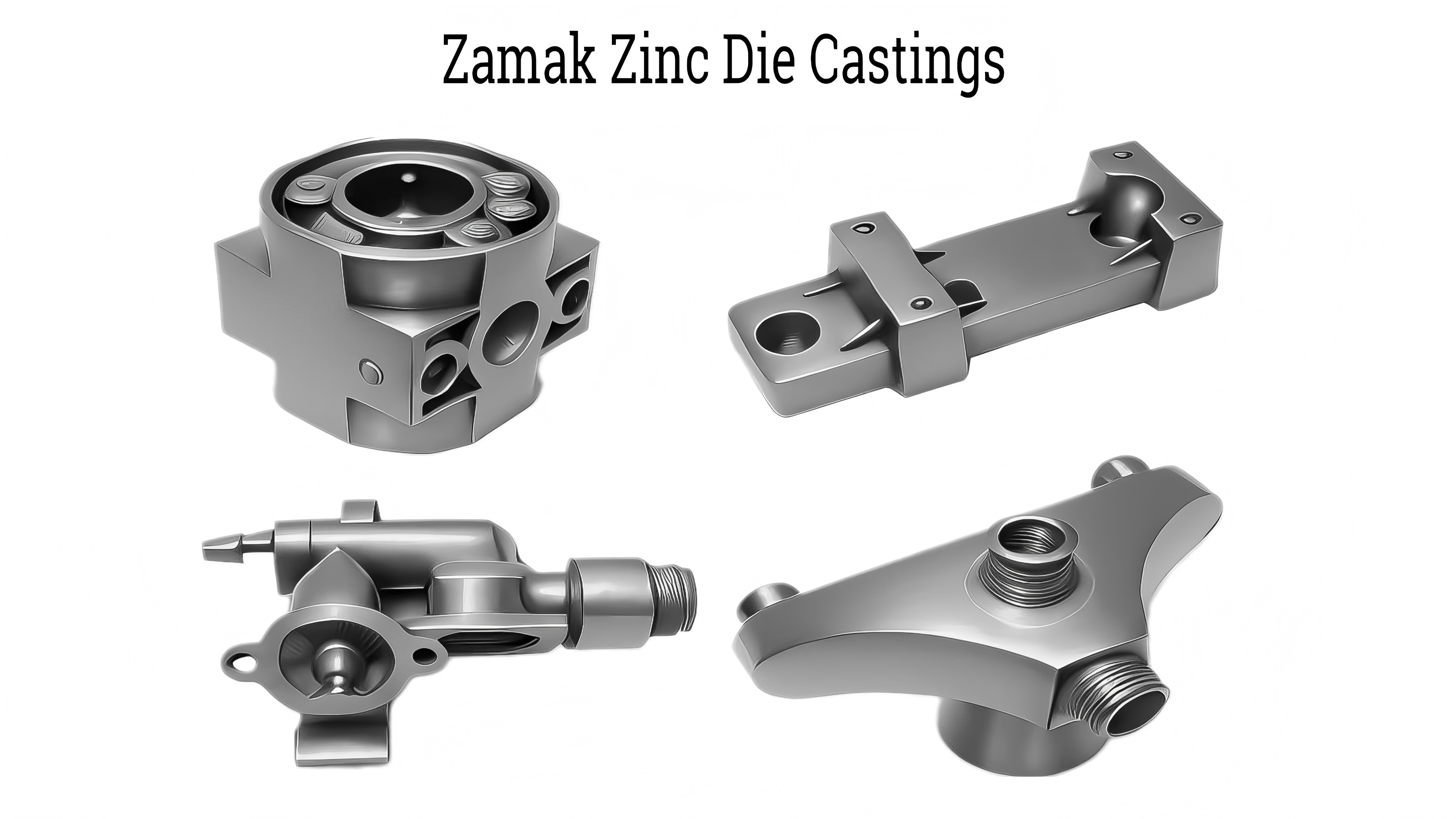

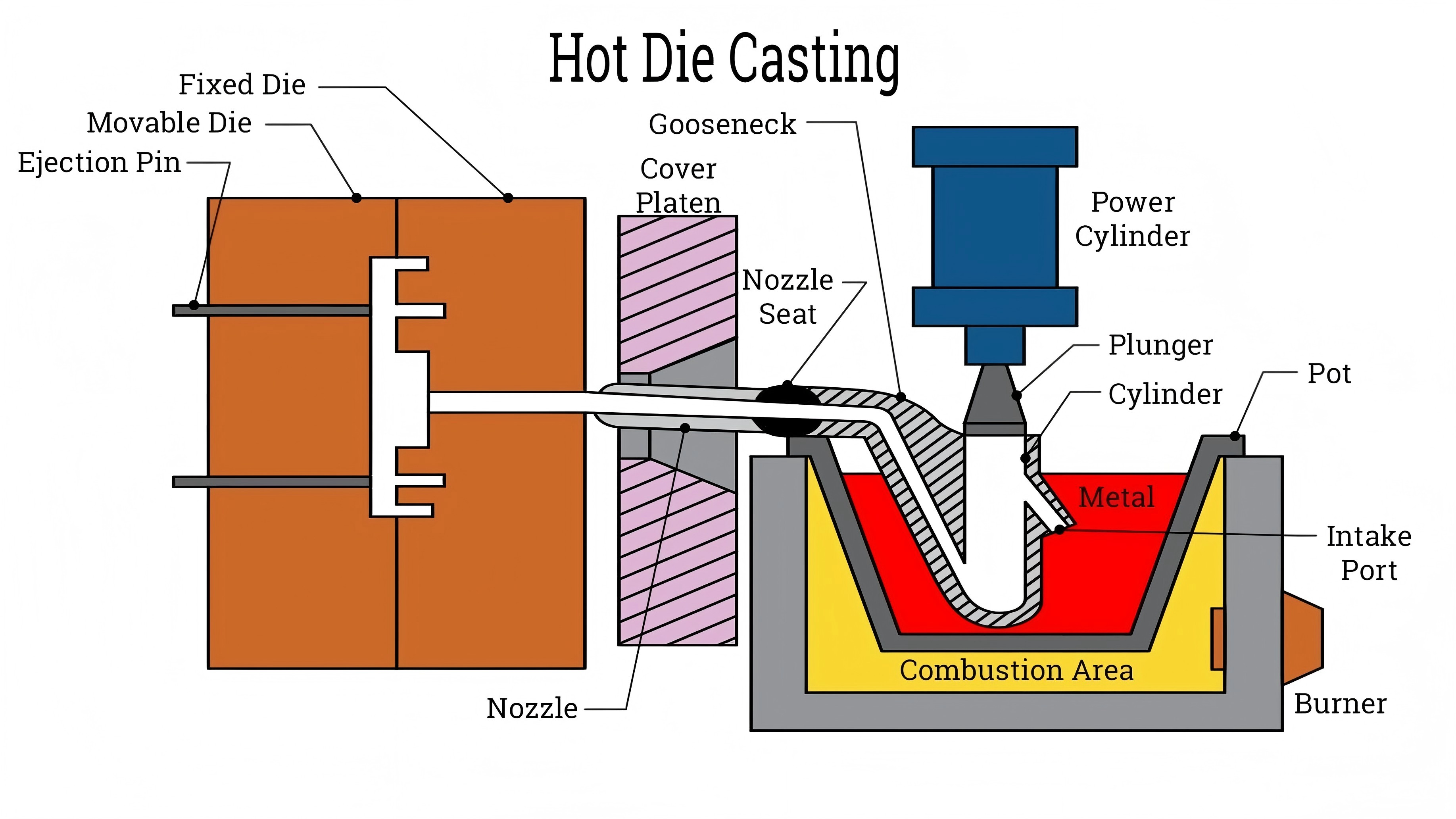

Sino Die Casting operates as a leading zinc die casting factory in Shenzhen, China, offering a full spectrum of services from design to production for clients worldwide. Founded in 2008, our high-tech enterprise integrates advanced technologies in mould manufacturing, die casting, and CNC machining to deliver zinc die cast components that excel in quality and performance. Our factory is equipped with state-of-the-art die casting machines capable of producing parts with exceptional dimensional accuracy and surface finish. We utilize high-pressure injection techniques to ensure that every zinc die cast part meets the stringent requirements of industries such as automotive, electronics, and telecommunications. Our CNC machining centers provide precise secondary operations, enhancing the functionality and aesthetics of your components. As an ISO 9001 certified zinc die casting factory, we uphold the highest standards of quality control throughout the production process. Our team of skilled technicians and engineers monitors every stage, from mold creation to final inspection, ensuring that your parts are manufactured to your exact specifications. We offer flexible production options, accommodating both rapid prototyping and large-scale mass production runs, providing you with the agility to respond quickly to market demands. Our factory's strategic location in Shenzhen allows for efficient logistics and timely delivery to clients across the globe. We are committed to sustainability, implementing eco-friendly practices in our operations to minimize our environmental impact. By choosing Sino Die Casting as your zinc die casting factory, you gain a partner dedicated to your success, offering comprehensive solutions that drive innovation and efficiency. We work closely with you to understand your unique needs, providing customized services that optimize performance and cost-effectiveness. Our global reach and commitment to excellence make us the ideal choice for all your zinc die casting requirements.