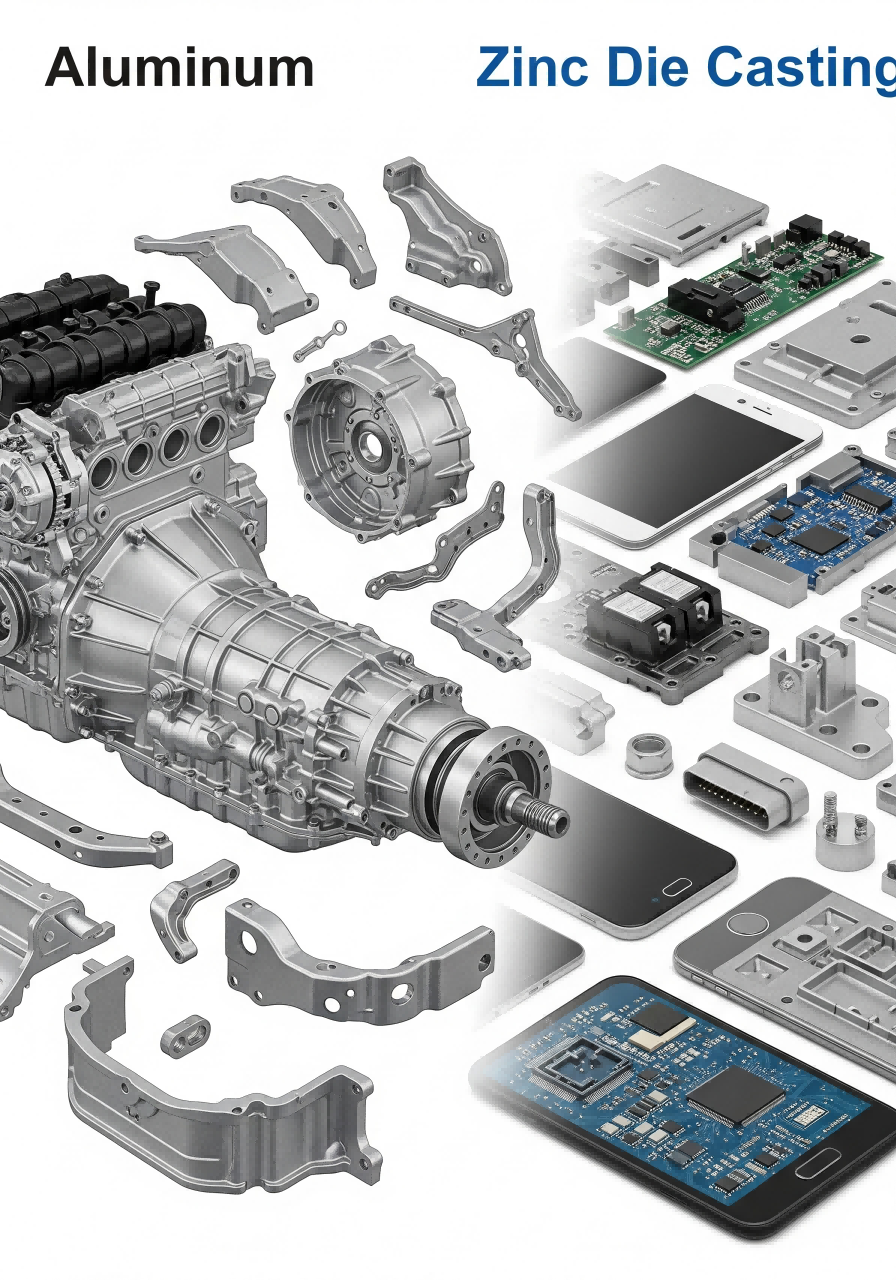

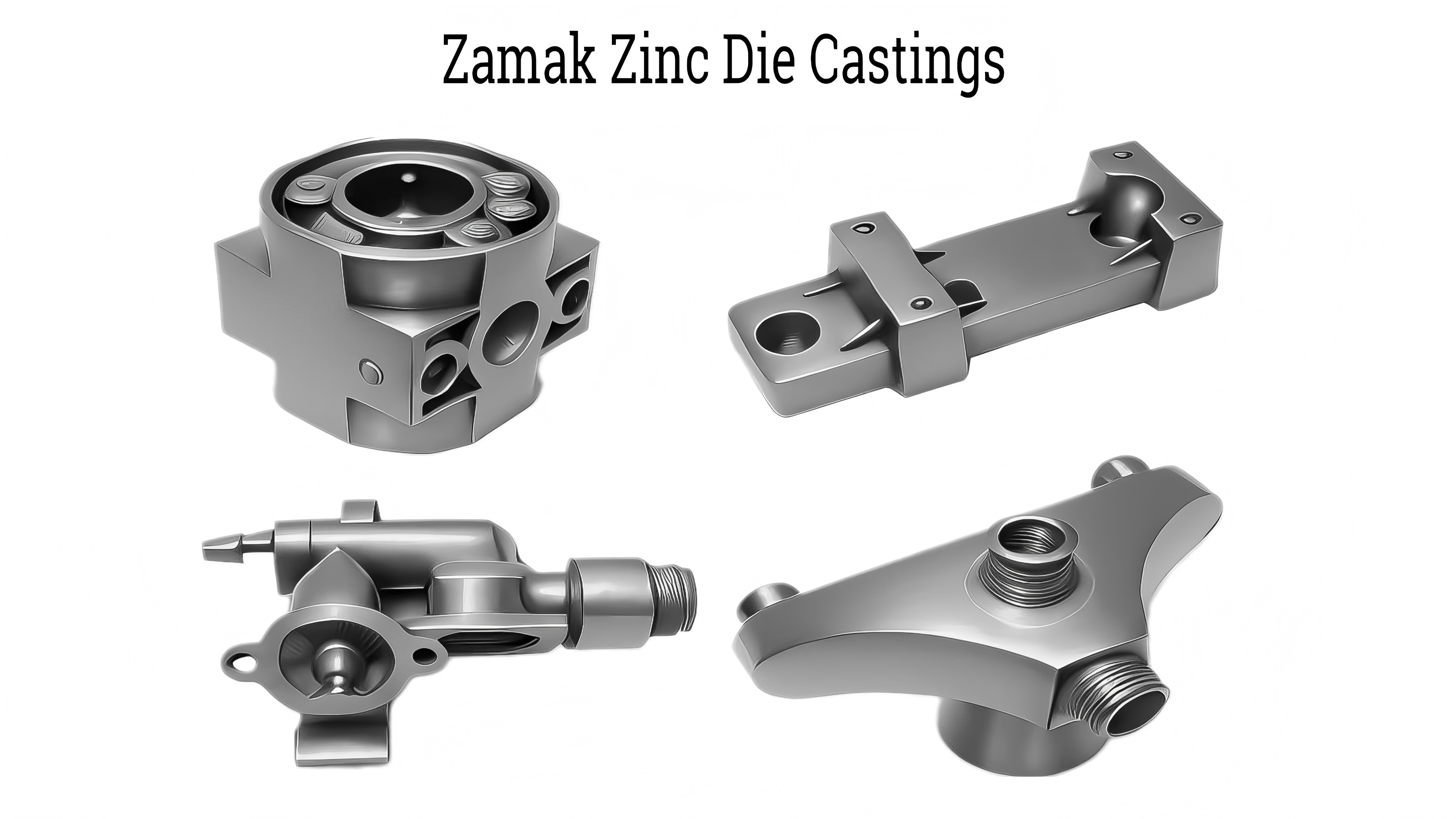

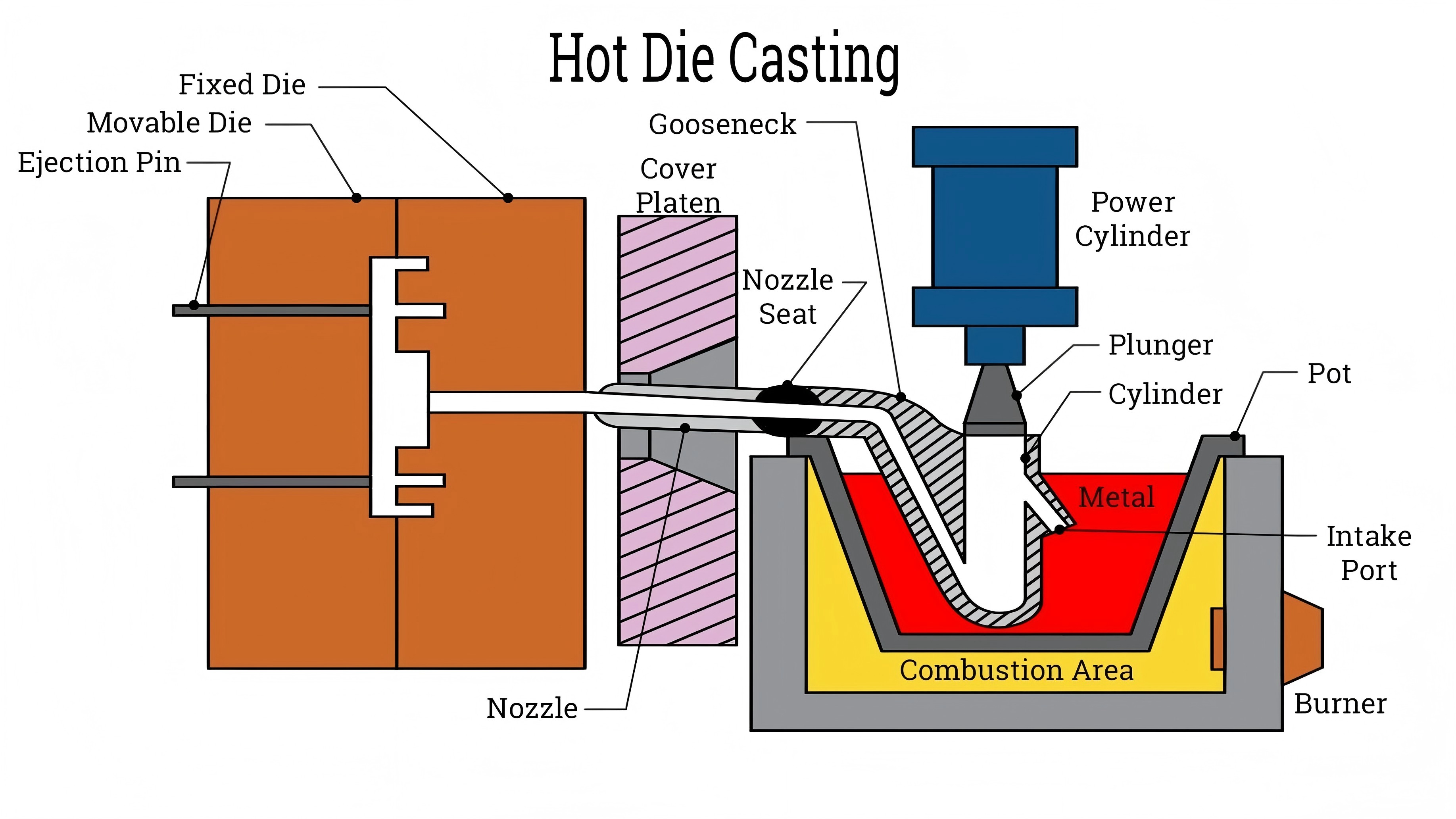

As a premier zinc die casting manufacturer, Sino Die Casting, located in Shenzhen, China, delivers unparalleled expertise in creating high-precision zinc die cast components for a diverse range of industries. Since our establishment in 2008, we have been at the forefront of integrating design, processing, and production to provide solutions that meet the evolving needs of our clients. Our zinc die casting manufacturing process begins with a thorough understanding of your requirements, allowing us to design molds that are optimized for performance and efficiency. We utilize advanced CAD/CAM software to create detailed mold designs, which are then manufactured using our precision CNC machining centers. Our state-of-the-art die casting machines inject molten zinc alloy under high pressure into the mold cavity, producing parts with exceptional dimensional accuracy and surface finish. As an ISO 9001 certified zinc die casting manufacturer, we adhere to strict quality control measures throughout the production process, ensuring that every component meets your exact specifications. Our team of experienced engineers and technicians works closely with you to provide customized solutions that enhance product functionality and reduce costs. We offer a range of secondary operations, including CNC machining, deburring, and surface treatment, to further refine your zinc die cast parts. Our manufacturing capabilities extend to both rapid prototyping and large-scale mass production, providing you with the flexibility to adapt to changing market conditions. With a global clientele spanning over 50 countries and regions, Sino Die Casting has established itself as a reliable and innovative partner in the zinc die casting industry. By choosing us as your zinc die casting manufacturer, you gain access to a comprehensive service that drives your business success through precision, quality, and efficiency. We are committed to continuous improvement, investing in the latest technologies and training to stay ahead of industry trends and deliver cutting-edge solutions.