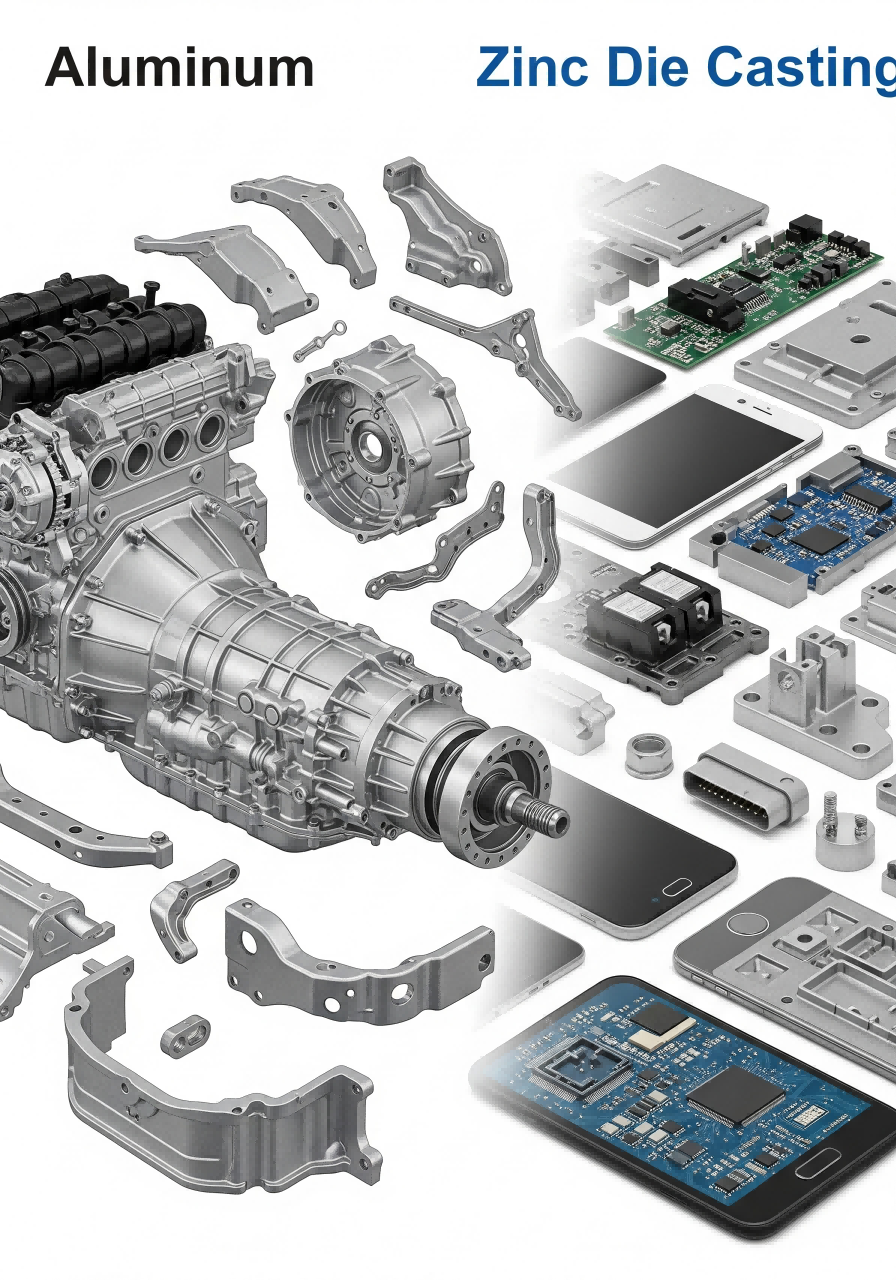

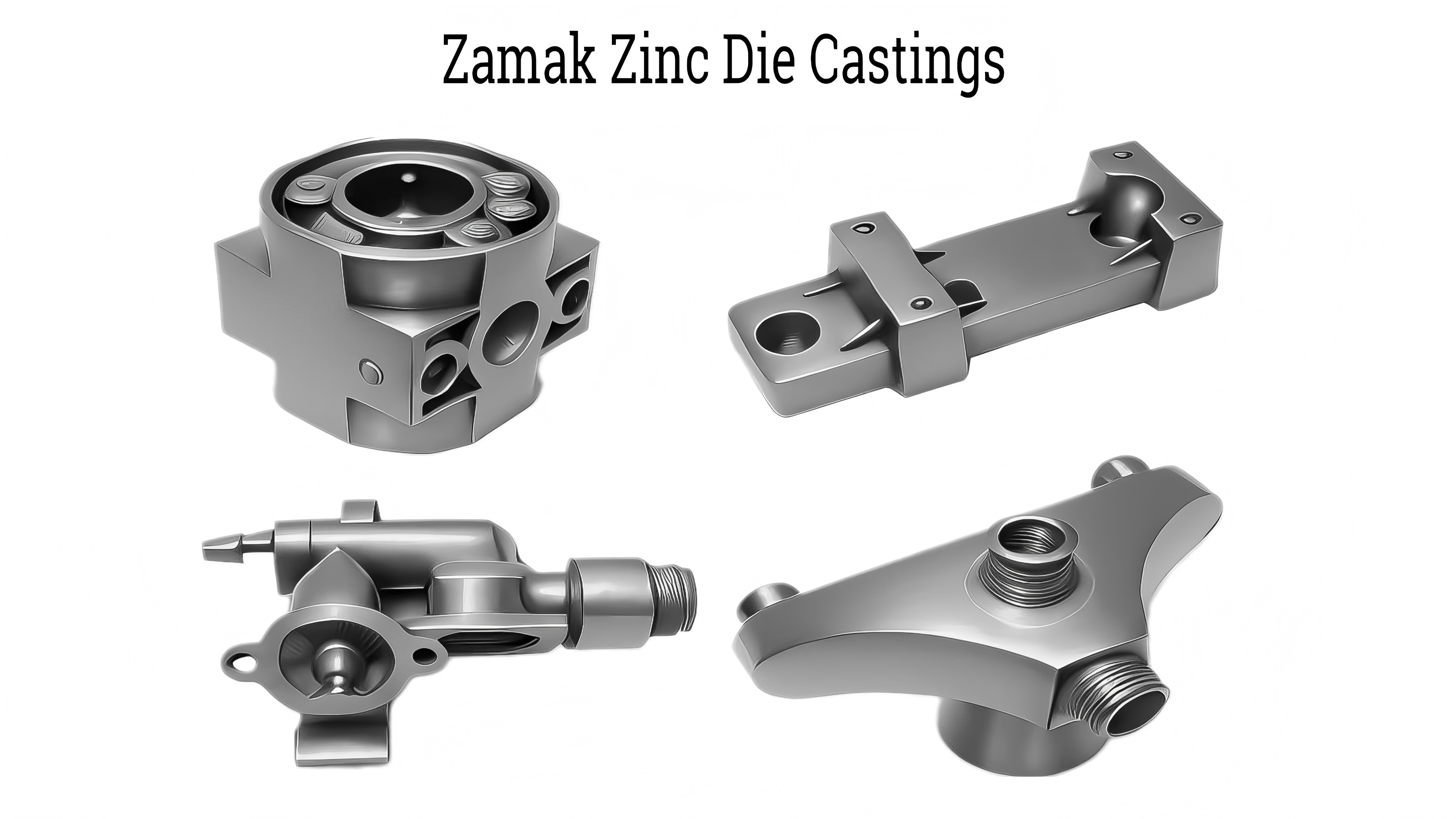

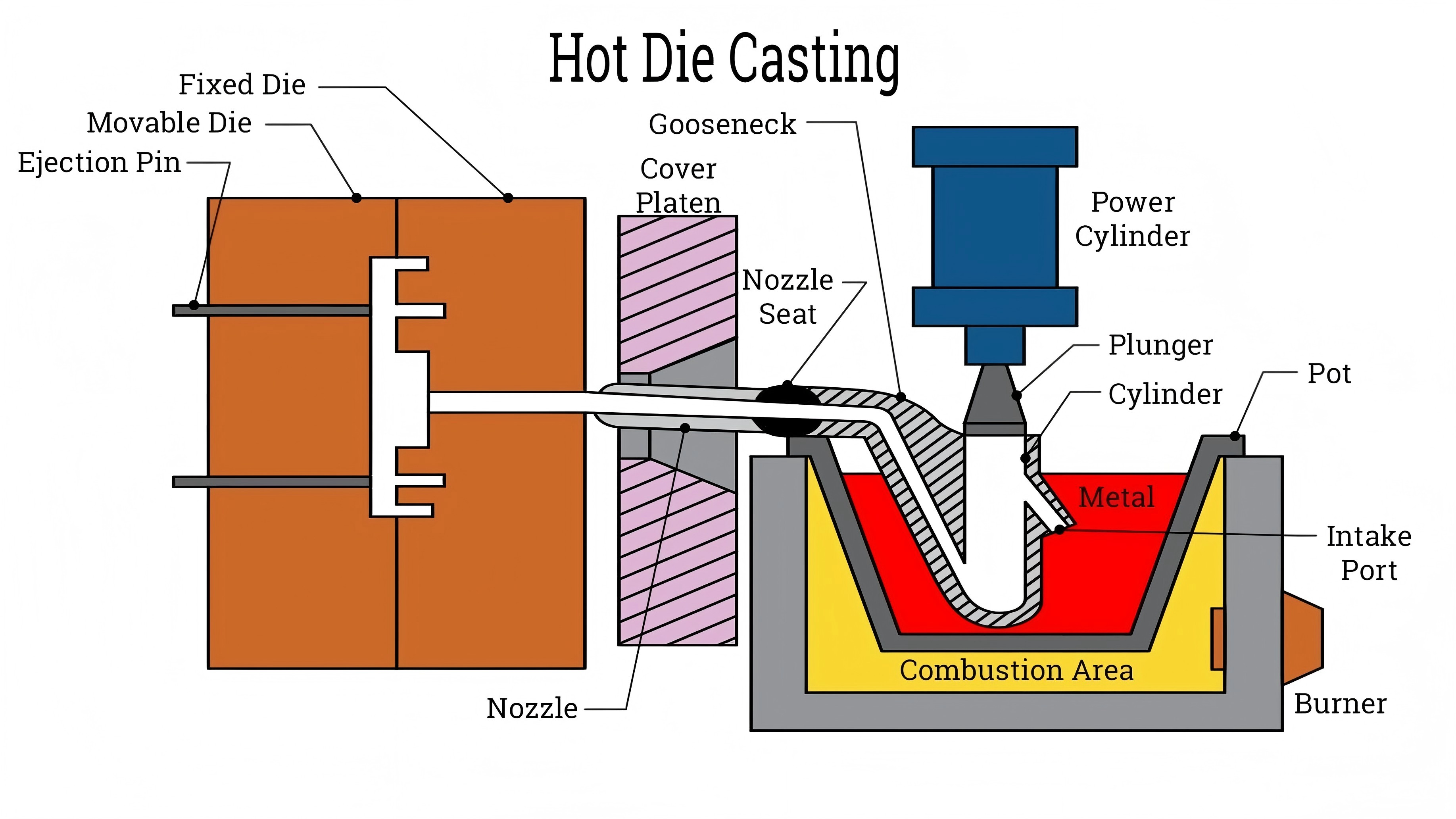

Sino Die Casting, a high-tech enterprise established in 2008 in Shenzhen, China, stands out as a leader in zinc alloy die casting. We integrate design, processing, and production seamlessly to offer top-notch services. Zinc alloy die casting is one of our core competencies. With our state-of-the-art facilities and a team of highly skilled professionals, we can handle complex and precise zinc alloy die casting projects. The automotive industry, for which we manufacture numerous components, benefits greatly from our zinc alloy die casting. We create parts with high dimensional accuracy, excellent surface finish, and superior mechanical properties. These parts are used in various automotive subsystems, from engine components to interior fittings. Our advanced technology ensures that the die casting process is optimized for minimal waste and maximum efficiency. We can control the temperature, pressure, and injection speed precisely during the casting process, resulting in high-quality zinc alloy parts. Moreover, our ISO 9001 certification guarantees that every zinc alloy die-cast part meets international quality standards. We conduct rigorous inspections at every stage of production, from mold making to the final product. Our ability to offer custom part production means that we can tailor the zinc alloy die casting to your specific requirements, whether it's a unique shape, size, or material property. We also provide a range of surface treatment options to enhance the appearance and durability of the zinc alloy parts. By choosing Sino Die Casting for your zinc alloy die casting needs, you gain a reliable partner that can take you from rapid prototyping to mass production, ensuring your products are of the highest quality and delivered on time.