Mene ne Alasadi Mai Ganye Suna Iyaka ga Ibi Mai Amintam ce

Takawa zuwa Kima, Manufofuri, da Nau'in Fadada EMI a Kasuwancin Makina

Kurotin yanzu suna buƙatar abubuwa da zasu iya tafiyyawa mai tsawon ƙarfi, alhakin kimiyyar kayan haihuwa, da rashin kuskuren elekturumagnatifiki ko EMI kamar yadda ake kira shi. Tsarin ganyawa ta aluminum ita ce ta fadi a cikin wannan matsala. Kayan aiki ya nuna yawan ƙarfi daga cikin injin take 40% kyautu karshen steel, wanda ke taimakawa wajen kiyaye kayan aiki ne sai dai idan yanayin yanayi ya ƙare. Wani dandalin girma ne shine aluminum ta halartar EMI signals, don haka kayan elektronics important kamar sensors da control systems suka karshe daga rashin kuskure. Sai dai, aluminum castings iya kama wall thicknesses zuwa 0.5 millimeters yayin da suka tsammanin matattun. Wannan ke ba da damar abokan tsaro su taron kayan kurotin masu ƙarfi, wanda ke kara kwayoyin kankaru take 7% kamar yadda ake rubuta ta U.S. Department of Energy a 2023.

Zaɓi na Gudumu: ECU Housings, Brake Calipers, da Structural Brackets

Kunshin ganyi alarminyam daga alarminyam yana iya mahimmacin kari don kari na budurwa da kai tsaye wajen halartar da ba zai iya kuskurewa ba. Dole gargaɗin gidan yakan yayar larada misali, wadannan abubuwan masu mahimmacin alarminyam don kare wahala mai amfani da karkashin elektromagnetic, wanda ke durce waɗannan kuskuren komputa maras karfin waɗe zai iya kuskure karfin mutum yayin da aka buƙata shi a matsayin mahaifi. Gwaji-gwaji mai tsokowa ta hanyar kunshi alarminyam yana iya kare tsokowa akan 8,000 psi kafin kafin ba tare da nuna alamar tushen ko kuskure. Lokacin da za a yi lafiya zuwa abubuwan masu mahimmacin kamar maganin ophanging, canza daga iron cast zuwa alarminyam yana iya haɗawa. Yawan kewaye ya rage da kusa zuwa 30%, wanda yana nufin inganci mai kyau saboda abubuwan kayan kewaye suna kare tasiri bisa hanyar da suka samu. Sai kuma, nasara na nasara (electric vehicles) suna da nasara kuma: batirin suke dauki karshen shekara saboda akwai kewaye kasa. Bayani daga SAE suna nuna inganci a cikin yanki ne tsakanin 12 zuwa 15%.

Zabbatar da Kyau Mai Alasadi na Aluminium Die Casting don Amfani a Makina

A380 vs. A360 vs. B390: Iyaka, Ra'ayin Kuturuwa, Takaifin Karbaƙi, da Fassalarin Kusurori

Kafin zaɓi na alloys don gyara, inggineruna dole ne su yi hisabi na abin da kayan aiki zai yi, yadda yake sauƙi wajen ƙirga, kuma wanda ke fitowa cikin hanyar budgiti. A380 ta zama tsawon bayani a cikin kayan aiki na otomatiko saboda tana fulewa sosai yayin cast, wanda ke taimaka wajen kula da waɗansu alamar hot tears, kuma tana ba da kyau mai adalci ga kuɗi, idan kuma bata kula da corrosion kamar wasu. Sai dai, akwai A360, wanda ta farko don kula da rust kuma tadaba tsarin juyawa. Wannan ke kama da abubuwa kamar coolant manifolds inda ruwa ke tafiya sosai cikinsu, dabamun ana amfani da shi, ko da ya kasance kwana iya cast kusa da A380. Don ayyukan masu mahimmanci kamar cylinder heads ko engine blocks inda kayan aiki taushe masa lokaci, masu gyara manyan sarari suna kan B390. Wannan alloy tana nuna karamin tsauri game da wear and tear amma tana da rashin tasiri saboda tafarka ke kunshe sosai yayin ejection daga molds.

| Sarari | A380 | A360 | B390 |

|---|---|---|---|

| Rabuwa | Binciken | Binciken | Tare daidai |

| Castability | Sunan Dadi | Yana da kyau | Daidai ne |

| Kula da Corrosion | Matsakaicin | Sunan Dadi | Mazama |

| Indeks Ƙasuwanci | 1.0 (Tsawon Bayani) | 1.3x | 1.7x |

Yaushe Taƙaitaccen Kwallon da Bukatar Tsaukar Bayarwa Ayyukan Tacewa Ta Influence Zabinta Na Alloy

Taƙaitaccen kwallon yana da mahimmacin mahimmacin wanne alloy zai dace. Lokacin da ake dealing da taƙaitaccen suttuka da ke kasa da kusa da 2 mm, dukkanin masu yi masa su zaɓi A380 mai tsarin mai tsarin saboda yake tace shafin kafin cikin bayarwa. Duk da haka, A360 zai dace sosai don abubuwan karkashin gaban saboda yake kara karanci, kuma yana nuna batun porosity. Abin da ya faru bayan bayarwa yana da mahimmanci kuma. B390 yana amfani da silicon, wacce ta rufe matakan cuttng har ma ƙaramin CNC anywhere from 15% to 25% lokacin da aka hada shi da A380. Don waɗannan abubuwan kuskuren da suka buƙatar iyakar iyaka game da plus ko minus 0.05 mm, A360 ta sami muhimmiyar halayen microstructure. Wannan halayen ta ba da cuttobi murya overall kuma ta taimaka wajen kiyaye iyaka na iyaka a cikin batches, wanda masu sarrafa production suna so shi a cikin ayyukan sadarwar su.

Tsari na Ginayen Aluminiyam a Caste

Dokokin Ililin Hunas: Kama’irorin Draft, Kwallon Tattara, Tsarin Hunas, da Safe Karɓaɓɓukan Karɓaɓɓuka

Albarkatu mai kyau ta ginawa ya fara ne a tsakon ililin hunas don arewa da kuskuretsu yayin amfani da rashin rashin yawa. Sa hannun draft tare da kama’i mai tsawo daga 1 zuwa 3 daraja yana taimakawa wajen bauta kwafin baƙi ba tare da karɓaɓɓuka. Lokacin da kwallon sun tattara, mafi kyau daga 2.5mm zuwa 4mm, yana taimakawa wajen arewa da rashin rashin sanya abubuwan da ke zama sunna ko kiran bubuwa. Yana da mahimmanci inda muka jiya hunas saboda tsarin sahih yana rage ganyun cin zarafi kuma yana sauƙaƙa shigowa. Kuma kar la’akari da yadda an tsara karɓaɓɓukan karɓaɓɓuka sun dole su kasance away from yanayin kasa don arewa da kuskuretsu. Duk wadannan alamar karatuke suna iya hada da mahimmanci a cikin kwalitatin bayanan.

- Kudaden draft sun kashe tsauraran yin nika da 40% a karkashin doka mai tsarra

- Idan aka tsaya girman kwanyar da ke wajen ±0.5 mm, zai taimaka wadanda suka faruwa a 90% na halayen

- Tsarin hanyar sauyin kwanyar ya samuwa mai sauƙi kuma ya kara gudunmawa kan kwanyar biyan kuɗi

- Yin iyaka mai kyau yana kula da abubuwan da ba su da girman daidai ba a cikin ±0.1 mm

A karkashin, amfani da waɗannan alakawar yana kasa rabiƙin binciken har zuwa ga 30% a cikin masoye mai yawa na otomatiko

Sakawa Tatturarrun Aiki da Kwayar Aluminium Ba Tare da Batutu Ba

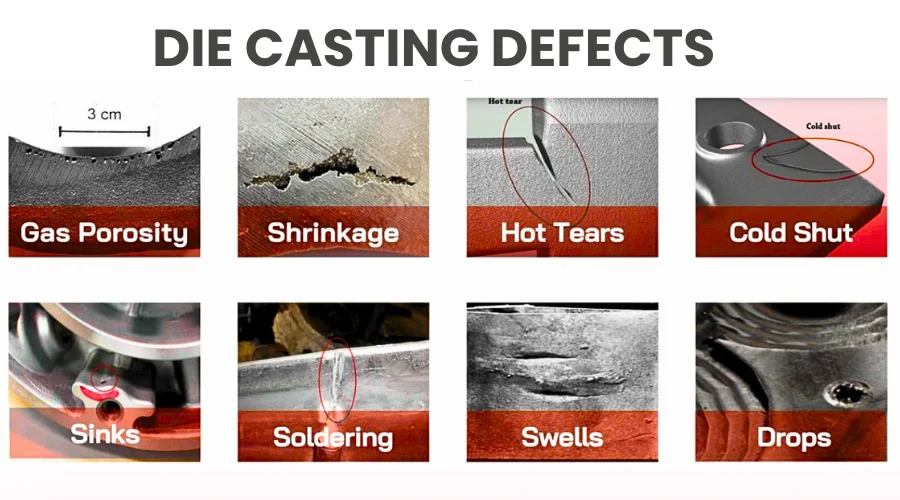

Taimakawa Porosity, Alamar Kwanyar, da Rarrafa Girman Tare da Simulation da Kontin Tsarin

Samun saukarwa mai tadadi yana nufin tunawa aƙalla a lokacin tsarin imbin kansu har abubuwan da suka shafi masa taɓawa. Masallaci na porosity ke kuskuren domin inganci ya ƙalshi ko gas wanda ya kamata a cikin abubuwa. Don fada wannan, masu amfani da injekshon ta alama ta aljunma (vacuum assisted injection) kuma kalmamar wasan gargajiya da aka kirkirar su don kawo fulfillment na cavity akan 99%. Alamar zuzu (sink marks) suna buƙatar saboda yanayin da suka kara karfi fiye da wadannan wasu a kayayyakin wacce ke ƙarfi. Amsun? Sauraro ido bayan tattalin arziki, kawo kari akan mita biyu, kuma canza sauya don ka samu sauya mai tadadi a cikin kayi. Rarraba girman kayi (dimensional drift) ke fito ne a matsayin rashin tadadi a lokacin abubuwa suna sanya bayan sauya. Yanar gizon production lines suna koyon waɗannan canje-canjeni ta hanyar amfanin computer models wanda aka kira FEA simulations wanda ke kiyaye yadda abubuwa suka kara, zuzu, ko kawo internal stresses. Lokacin da masu amfani suna duba melt temps, injekshon pressures, da cycle times waɗannan data suna shiga cikin kontrololin atomatik. Wannan hanyar yin aiki ta kawo duka abubuwan da suka koma a halitta kusa zuwa a halitta kusa zuwa mita hudu, wanda ke kawo sharuddan mai zurfi da aka haɗa da masu amfani na automotive masu mahimmanci don kayayyaki inda matattuwa ke da mahimmanci.

Tambayoyi Masu Yawan Faruwa

Wanne ne mai kyau a cikin zane tsare da aluminum dar alama kan steel don abubuwan na otomatik?

Zane tsare da aluminum yana karkashin haliya ta hanyar 40% karfi duk sararin steel, kuma tana gudanar da haliyar masifa mai tsoro. Kuma tana ba da rashin karkashin electromagnetic (EMI) mai zurfi, ta kawo tsaro ga maƙalar elektoronik mai mahimmanci.

Mene ne ona aluminum an son amayyanshi a gyara brake calipers da ECU housings?

Tsaro da aluminum zuwa wasan yanke da sauri da iya samun girman dabin daga baya, kamar 8,000 psi ga brake calipers, suna kiyaye tsaro da rashin kuskure. Kakkaunas ta EMI tana muhimmiyar rawa ga ECU housings, ta kawo tsaro ga ayyukan elektoronik mai mahimmanci.

Wanne ne jinsi na aluminum alloy ke kula da kasuwanci sosai don amfani na otomatik?

A380 ita ce standard saboda tsakartar sa na castability, kasuwanci, da kankara mai tsere, kuma ya nuna amfani mai kyau, irin kansa da shakatawa mai adadi.

Yaushe design for manufacturability ke ƙara ingancin aluminum die casting?

Tare da amfani da koyon sharuɗɗan geometry kamar drafting angles, uniform wall thickness, da saukar da wurin parting line, masu yi samfur da bisa iya kara kuskuren samfur, kara rarin baki, da sauya tsarin production, kada kusan kwaliti na samfur.

Teburin Abubuwan Ciki

- Mene ne Alasadi Mai Ganye Suna Iyaka ga Ibi Mai Amintam ce

- Zabbatar da Kyau Mai Alasadi na Aluminium Die Casting don Amfani a Makina

- Tsari na Ginayen Aluminiyam a Caste

- Sakawa Tatturarrun Aiki da Kwayar Aluminium Ba Tare da Batutu Ba

-

Tambayoyi Masu Yawan Faruwa

- Wanne ne mai kyau a cikin zane tsare da aluminum dar alama kan steel don abubuwan na otomatik?

- Mene ne ona aluminum an son amayyanshi a gyara brake calipers da ECU housings?

- Wanne ne jinsi na aluminum alloy ke kula da kasuwanci sosai don amfani na otomatik?

- Yaushe design for manufacturability ke ƙara ingancin aluminum die casting?