Why Aluminum Die Casting Is Critical for Automotive Reliability

Meeting Thermal, Mechanical, and EMI Shielding Demands in Modern Vehicles

Cars today need parts that can handle intense heat, constant mechanical stress, and electromagnetic interference or EMI for short. Aluminum die casting stands out when it comes to these challenges. The material conducts heat away from engines about 40 percent quicker than steel does, which helps keep components intact even when temperatures spike. Another big plus is how aluminum naturally blocks EMI signals, so important electronics like sensors and control systems stay protected from unwanted interference. Plus, aluminum castings can maintain wall thicknesses down to just 0.5 millimeters while still being strong enough structurally. This allows manufacturers to create lighter vehicle parts, something that actually boosts fuel economy by around 7% according to research from the U.S. Department of Energy back in 2023.

Real-World Impact: ECU Housings, Brake Calipers, and Structural Brackets

Aluminum die casting plays a vital role in ensuring safety and reliability for systems where failure isn't an option. Take engine control unit housings for example these components depend heavily on aluminum's ability to block electromagnetic interference, which stops those annoying computer glitches that might mess up how the car responds when needed most. Brake calipers made through die casting can handle pressures over 8,000 psi again and again without showing signs of wear or breaking down. When it comes to structural parts like suspension mounts, switching from cast iron to aluminum makes a big difference. The weight drops by around 30%, which means better crash protection since lighter materials absorb impact differently. Plus, electric vehicles benefit too their batteries last longer between charges because there's simply less weight to carry around. Studies from SAE back this up showing improvements in range between 12 to 15 percent.

Selecting the Right Aluminum Die Casting Alloy for Automotive Use

A380 vs. A360 vs. B390: Strength, Castability, Corrosion Resistance, and Cost Trade-offs

When picking alloys for manufacturing, engineers need to consider what the part will actually do, how easy it is to make, and what fits within budget limits. A380 has become pretty much standard in automotive parts because it flows well during casting which helps prevent those annoying hot tears, plus it gives decent value for money even if it doesn't resist corrosion as well as some others. Then there's A360, which stands out for keeping rust at bay and maintaining seal integrity. That makes it great for things like coolant manifolds where water is constantly running through them, although it does cast a bit worse than A380. For really tough jobs such as cylinder heads or engine blocks where parts get worn down over time, manufacturers often turn to B390. This alloy packs serious punch against wear and tear but comes with tradeoffs since its brittleness means it cracks more easily when ejected from molds.

| Property | A380 | A360 | B390 |

|---|---|---|---|

| Strength | Moderate | Moderate | High |

| Castability | Excellent | Good | Fair |

| Corrosion Res. | Average | Excellent | Poor |

| Cost Index | 1.0 (Baseline) | 1.3x | 1.7x |

How Wall Thickness and Post-Casting Machining Needs Influence Alloy Choice

The wall thickness has a big impact on which alloy works best. When dealing with thin walls under about 2 mm, most manufacturers go with high fluidity A380 because it fills cavities completely during casting. On the flip side, A360 tends to be a better choice for thicker sections since it shrinks less, making porosity issues less likely. What happens after casting matters too. B390 contains more silicon, which wears down cutting tools faster during machining. This actually increases CNC processing costs anywhere from 15% to 25% when compared against A380. For those tricky parts that need really tight tolerances around plus or minus 0.05 mm, A360 stands out again thanks to its uniform microstructure. This characteristic leads to cleaner cuts overall and helps maintain consistent surface finishes across batches, something production managers really appreciate in their daily operations.

Design for Manufacturability in Aluminum Die Casting

Key Geometry Rules: Draft Angles, Uniform Walls, Parting Line Placement, and Ejection Safety

Good design for manufacturing starts right at the basics of geometry to stop those pesky defects from happening while making things easier to produce. Getting draft angles just right around 1 to 3 degrees makes parts pop out smoothly without scratching surfaces during removal. When walls are consistently thick across the piece, preferably somewhere between 2.5mm and 4mm, it helps prevent uneven cooling problems that can warp parts or create annoying internal bubbles. Where we put those parting lines matters too because smart positioning cuts down on flash and saves time on extra finishing work later. And don't forget about how ejection pins are arranged they need to stay away from areas that carry weight to keep everything from twisting out of shape. All these little details actually make a big difference in final product quality.

- Draft angles cut ejection force by 40% versus vertical walls

- Maintaining wall thickness within ±0.5 mm variance eliminates sink marks in 90% of cases

- Thoughtful parting line design simplifies die construction and lowers finishing costs

- Optimized ejection prevents dimensional inaccuracies beyond ±0.1 mm

Collectively, adherence to these rules reduces scrap rates by up to 30% in high-volume automotive production.

Ensuring Consistent Quality and Defect-Free Aluminum Die Casting

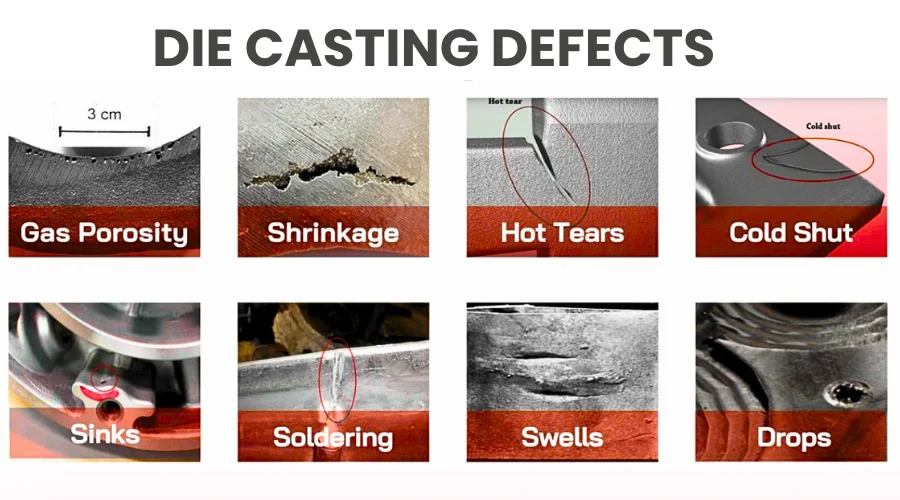

Preventing Porosity, Sink Marks, and Dimensional Drift Through Simulation and Process Control

Getting consistent quality means thinking ahead in the process design stage rather than waiting for problems to show up later. Porosity issues usually happen when air gets trapped or volatile gases form inside the material. To fix this, manufacturers often use vacuum assisted injection methods along with specially designed mold vents that help achieve cavity fills above 99%. Sink marks appear because certain areas shrink more than others in thicker parts. The solution? Make sure walls have consistent thickness across the board, keeping variations below half a millimeter, and adjust cooling so it happens evenly throughout the part. Dimensional drift comes from uneven shrinking as materials cool down after melting. Modern production lines predict these changes using computer models called FEA simulations that track how much things shrink, warp, or develop internal stresses. When factories monitor melt temps, injection pressures, and cycle times continuously, they can feed this data into automatic controls. This approach cuts defects nearly in half and keeps important measurements accurate within quarter of a millimeter, which meets those strict requirements set by top tier automotive suppliers for parts where reliability matters most.

FAQ

What is the main advantage of aluminum die casting over steel for automotive parts?

Aluminum die casting conducts heat approximately 40% more efficiently than steel, effectively managing intense engine heat. It also offers superior electromagnetic interference (EMI) shielding, preserving the integrity of sensitive electronics.

Why is aluminum preferred in the production of brake calipers and ECU housings?

Aluminum's resistance to wear and its ability to handle high pressures, such as 8,000 psi for brake calipers, ensure durability and reliability. Its EMI blocking capabilities are vital for ECU housings, protecting critical electronic functions.

Which aluminum alloy is most cost-effective for automotive use?

A380 is considered the standard due to its balance of castability, cost, and moderate strength, making it suitable for many automotive applications. It provides excellent value, despite having average corrosion resistance.

How does design for manufacturability improve aluminum die casting?

By adhering to key geometric principles such as drafting angles, uniform wall thickness, and optimized parting line placement, manufacturers can minimize defects, reduce scrap rates, and streamline production, enhancing overall product quality.