Zabinta da Amfani da Wata Fulani Mai Kyau don Tsawon Zamantakewa na Karin Kari

H13 vs. DIN 1.2367 vs. Alternatives: Thermal Fatigue, Hardness, da Cost Trade-offs

Kada kake amfani da sarufin die casting da ke tsawon gargadi na hankali, zai bambanta yadda aka zauna makamashi. H13 tool steel ya barci kan thermal fatigue saboda haɓakar chromium, molybdenum, da vanadium, wanda ya kama shi ya dura har zuwa a 600 daraja Celsius. DIN 1.2367 yana bada kyau a kula da garkamarar sai kafin amma babu kyau kamar sa a kula da thermal shock ta 10 zuwa 15%, don haka yana aiki kyau inda ba za a yi waƙaɗin cycle amma garkama yana girma. Zaɓaɓɓen da qarante kamar P20 steel zai iya aiki don samun ruwa mai yawa a zurfi mai qarante, amma irin sabbabbin waɗannan ke kawo har maƙaɗawa yayin da aka yi waƙaɗin 150,000 cycles lokacin da aka amfani da aluminum. Don ayyukan samar da abubuwan da suka wuce, kara kwarewar karɓuwa a kula da resistance to thermal fatigue yana da manhajar kyau saboda kariyan da za su fito ne zai biya har zuwa $20,000 per mold game da sabbin sarufi da amincewar lokaci bisa nazarin Ponemon daga 2023.

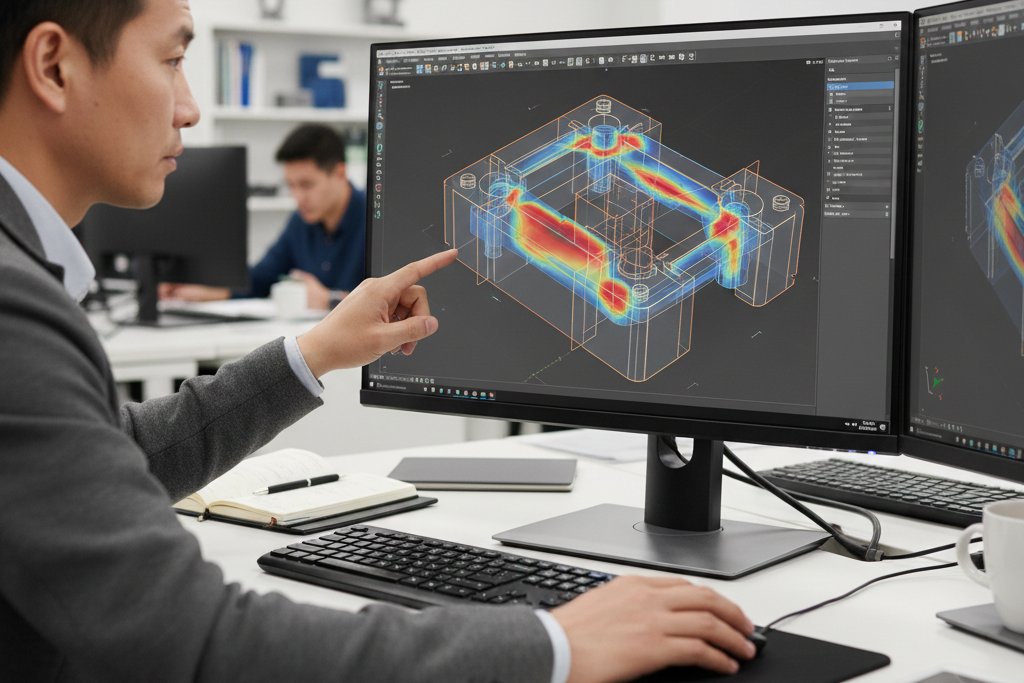

Inganta Tsarin Kare: Samun Kishayar Hardness (48—52 HRC), Toughness, da Daidaiton Microstructural

Ƙayyade waraka gaske ta halitta tare da tsauri ne domin in nanya iya samun abubuwan dake uku. Lokacin da ake yi shi daidai, mai zuwa uku kamar yadda ya kasance 600 digiri Silisiya yana zama wajen baya daga 48 zuwa 52 a cikin ma'adinan Rockwell. Wannan baya lafiyar hanyar sauya har ma babu karfi sosai ga abubuwan dake uku. Amma idan gwajiyan yanruwa sun fara ƙasa fi 5 digiri yayin rage, abubuwan faruwa sun faru. Muna ganin carbides sun kafa inda ba su kamata ba, wanda ke barce tsarin ma'adinin lokaci. Lura na sarrafa ta fada cewa amfani da proses mai zuwa biyu yana haifar da motalolin yanzu kamar 30% saboda yana taimakawa wajen kontine kusurwar kayan aiki. Kuma za mu yi mataki don kula da furnace suna da calibrations daidai. Hanyoyin rage da ke iya canzawa karami ne. Canje-canjen kamar 1% ne kama ya kara karfin rage a halitta, don haka takardun talabijin suna yin aiki a wannan al'amuran.

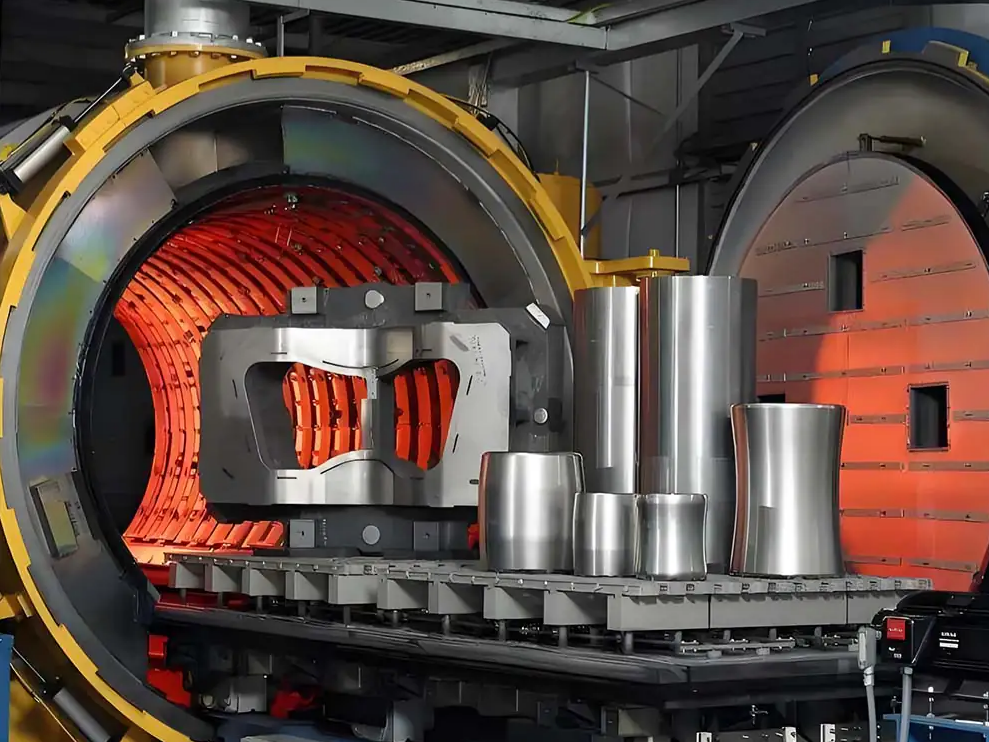

Gine-Gine Waraka Gaske a Cikin Motalolin Die Casting

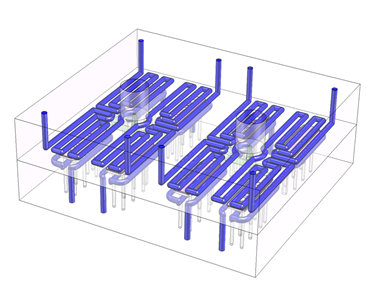

Tsarin Channel Na Cooling, Cooling Mai Dabara, da Kontin Tsarin Tsangayar Harshen Don Kare Kare Kari

Samunsa tsarin tsangayar harshen yana fara daga wanda yake tsarin hanyoyin cooling. Hanyoyin da aka yi a zaman kansu na straight line suna fitar da wuraren harshen (hot spots) da ke iya haifar da matsaloli a zaman kansu ta hanyar matsalolin harshen. Taimakan yanzu teknologin conformal cooling, inda hanyoyin da aka print a 3D suna da dabi'u da shape na mold kamar yadda aka yi ba tare da kawo hanyoyin straight line ba. Wannan yake baɗawa harshen a tsauraran yau da kullun a karkashin abu. Muna ganin farko bayan tsangayar harshen ya kara da kusa zuwa 40% a waniƙiƙin wuraren, wanda yana nufin cracks daga heat checking su fara a karshe a cikin production cycles. Kama da tsaurin harshen na mold ta 300 degrees Celsius yana taimakawa wajen kare warping. Yawan wasan yana yin amfani da wannan tsarin cooling mai zurfi tare da sensors da ke kara tsangayar harshen a real time, kamar yadda yake ba operators damar canza coolant flow lokacin da shaguwar yana canzawa a cikin manufacturing runs.

Karin Bayani na Tsawon Cin Kafa: Yaushe Tatsuniya Ta Haɗa Da Zinayen Cin Kafa a Cikin Furfure da Zinare

Kada kuma kowane matakan amfani na yawa suna gudua, shine hanyar daya daya a cikin rage da kuma rage waɗannan matakan suka fara kullewa. Kullum lokacin da tsawon shan ruwa ya tafi 200 digiri Silisiyus a karkashin wannan halayen, dukkanin alamuƙan zafi suna tafawa a cikin kayan aiki. Bayan kamar mahimman goyon matakan, duk wadannan zafin alamuƙan da suka kwatanta suna nuna alamuƙan zafi masu rage a kan sararin. Duk lokacin da abubuwan bayanai sun saba, misali, ne ya fi karin koma goma biyu, wanda ya kirkirar matsalolin ruwan dare mai tsoro sosai. Ma'amurorin sun samun cewa kawai taɓayar lokacin rage kamar biyar koma ashirin ko kama dabarar girma na tsawon shan ruwa ba tare da iskar karami, zai iya raguwa matsalolin ruwan dare masu tsoro kamar talatin hudu. Wadannan nau'ikan gyara suna iya canza halayen a tsariyan sarrafa da ma'amurori na elektronics inda yadda tsawon inzogan matakan ke iya tasowa kan kama’irin amfani da kuma kwaliti na abubuwan da aka kammala.

Inganta Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin

Abubuwan da ke da mahimmanci: Fillets, Radii, Ra'ayoyin Ra'ayoyin, da Tsarin Ra'ayi don rage Matsayin Matsin

Waɗannan kusurwa masu kaifi da kuma canji na gaggawa a siffarsu suna zama ainihin wuraren matsala sa'ad da abubuwa suka faɗaɗa saboda zafi ko kuma a matsa musu. Suna haifar da matsin lamba wanda kawai ke hanzarta inda fashewa ke farawa. Idan muka kara wadannan kyawawan kusurwa masu zagaye (aƙalla radius na 1.5mm), yana yada zafi da ƙarfin inji a kan manyan yankuna, wanda ke nufin ƙananan wurare don fashewa. A cewar wasu binciken da aka buga a cikin Jaridar Kasa da Kasa ta Metalcasting a shekarar 2022, kayan kwalliyar aluminum tare da fillet masu girman gaske a zahiri suna tsakanin 40% zuwa 60% fiye da waɗanda ke da kaifi. Samun kusurwoyin da suka dace ma yana kawo canji sosai. Tsayawa a cikin digiri 1 zuwa 3 a kowane gefe yana taimakawa wajen kauce wa janyewa a lokacin fitarwa, wanda shine daya daga cikin manyan dalilan da ke haifar da lalacewar farfajiya da kuma girman girman lokaci. Inda muka kafa layin rabuwa ma yana da muhimmanci. Sanya su daga wuraren da suke ɗaukar mafi yawan tasiri yana sa abubuwa su zama masu sauƙi, kuma ƙara siffofi masu ƙwanƙwasa a wuraren tuntuɓar yana rage ƙarancin damuwa a daidai inda matattarar suka haɗu. Duk waɗannan ƙananan gyare-gyare na ƙira tare suna taimakawa wajen yaki da fatigue cracking kuma zai iya ajiye masana'antun ko'ina daga $ 300,000 har zuwa kusan dala miliyan lokacin da suke buƙatar sake gina kayan motsa jiki.

Tsara tsarin fitarwa da tsarin kwararar ruwa don karko na gyaran gyare-gyare

Tsarin Gating, Venting, da Ejector don Rage Warpage, Sinking, da kuma lalacewa na gida

Lokacin da aka inganta ƙofar da kyau, narkar da ƙarfe yana gudana cikin rami sosai, wanda ke taimakawa rage matsalolin rikice-rikice waɗanda ke haifar da matsalolin damuwa na ciki, ɓangarorin warping, da kowane irin lahani na farfajiya. Ƙofofin da aka saka a wurare da suka dace suna taimaka wajen kawar da waɗannan iskar gas masu ban haushi, don haka, ba ma ganin ƙarancin ƙwayoyin da ke cikin ginin, ba ma ganin alamun ruwa da ke cikinsa, kuma ba ma ganin matsin da zai raunana ginin. Don tsarin fitarwa, daidaituwa shine mabuɗin. Yana bukatar ya rarraba karfi daidai a ko'ina cikin duk wani sashi da ake yi. Ƙarƙashin ƙuƙwalwa masu dacewa suna aiki mafi kyau idan suna da girman daidai, in ba haka ba sassan zasu iya gurbata ko wasu yankuna zasu iya sawa da sauri bayan amfani da maimaitawa. Masu kera kayayyaki da ke aiki a kan sikelin suna amfana da irin wannan ci gaba. Nazarin ya nuna cewa kusan kashi 40 cikin ɗari na lalacewar inji yana faruwa da wannan hanyar, ƙari kuma yana kawar da yawancin wuraren da aka saba. A bayyane yake cewa, matattarar tana da tsawon rai, amma abin da ya fi muhimmanci shi ne a ci gaba da daidaita ma'aunin ko da bayan an yi dubban abubuwa iri ɗaya kowace rana.

Tambayoyi Masu Yawan Faruwa

Me ya sa H13 kayan aiki karfe aka fi son ga matattarar simintin gyare-gyare?

H13 kayan aiki karfe ne da aka fi so saboda yana tsayayya da gajiya mai zafi saboda abun da ke ciki na chromium, molybdenum, da vanadium, yana riƙe da kwanciyar hankali har ma a yanayin zafi mai yawa a kusa da digiri 600 Celsius.

Menene ya sa DIN 1.2367 kayan aiki karfe mai kyau wani zaɓi?

DIN 1.2367 kayan aiki karfe rike tasiri mafi alhẽri daga H13, sa shi manufa domin yanayi da karfi tasiri amma m thermal hawan keke.

Ta yaya zafin jiki magani iya inganta kayan aiki karfe yi?

Maganin zafi mai kyau, musamman ma sau uku a kusa da digiri 600 Celsius, yana cimma daidaituwa tsakanin taurin da taurin, inganta ƙarfin ƙarfe ba tare da lalata tsarinsa ba.

Ta yaya sanyaya mai sanyaya ke inganta ƙirar simintin gyare-gyare?

Tsarin sanyaya yana amfani da tashoshin sanyaya na 3D da aka buga waɗanda suka dace da siffar ƙirar, wanda ke haifar da cire zafi daidai da rage damuwa da zafi da karkatarwa.

Yaya abubuwa kamar fillet suke shafan tsawon rayuwar mold?

Abubuwan ƙira kamar fillets suna taimakawa rarraba damuwa da zafi a kan manyan yankuna, rage wuraren fara fashewa da haɓaka karko na ƙirar.

Teburin Abubuwan Ciki

- Zabinta da Amfani da Wata Fulani Mai Kyau don Tsawon Zamantakewa na Karin Kari

- Gine-Gine Waraka Gaske a Cikin Motalolin Die Casting

- Inganta Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin Tsarin

- Tsara tsarin fitarwa da tsarin kwararar ruwa don karko na gyaran gyare-gyare

-

Tambayoyi Masu Yawan Faruwa

- Me ya sa H13 kayan aiki karfe aka fi son ga matattarar simintin gyare-gyare?

- Menene ya sa DIN 1.2367 kayan aiki karfe mai kyau wani zaɓi?

- Ta yaya zafin jiki magani iya inganta kayan aiki karfe yi?

- Ta yaya sanyaya mai sanyaya ke inganta ƙirar simintin gyare-gyare?

- Yaya abubuwa kamar fillet suke shafan tsawon rayuwar mold?