Selecting and Treating the Right Tool Steel for Die Casting Mould Longevity

H13 vs. DIN 1.2367 vs. Alternatives: Thermal Fatigue, Hardness, and Cost Trade-offs

When dealing with die casting molds that go through intense thermal cycles, the choice of steel really affects how long they last. H13 tool steel stands out for resisting thermal fatigue thanks to its mix of chromium, molybdenum, and vanadium, which keeps it stable even at around 600 degrees Celsius. DIN 1.2367 handles impacts better but isn't as good against thermal shocks by about 10 to 15 percent, so it works better where there aren't too many cycles but impacts are strong. Cheaper options such as P20 steel can work for smaller runs at lower temperatures, though these usually give way well before reaching 150,000 cycles when used with aluminum. For big volume operations, focusing on thermal fatigue resistance makes sense because cracks forming early can cost upwards of $20,000 per mold just for replacements and lost time according to Ponemon's research from 2023.

Optimizing Heat Treatment: Achieving Balanced Hardness (48—52 HRC), Toughness, and Microstructural Stability

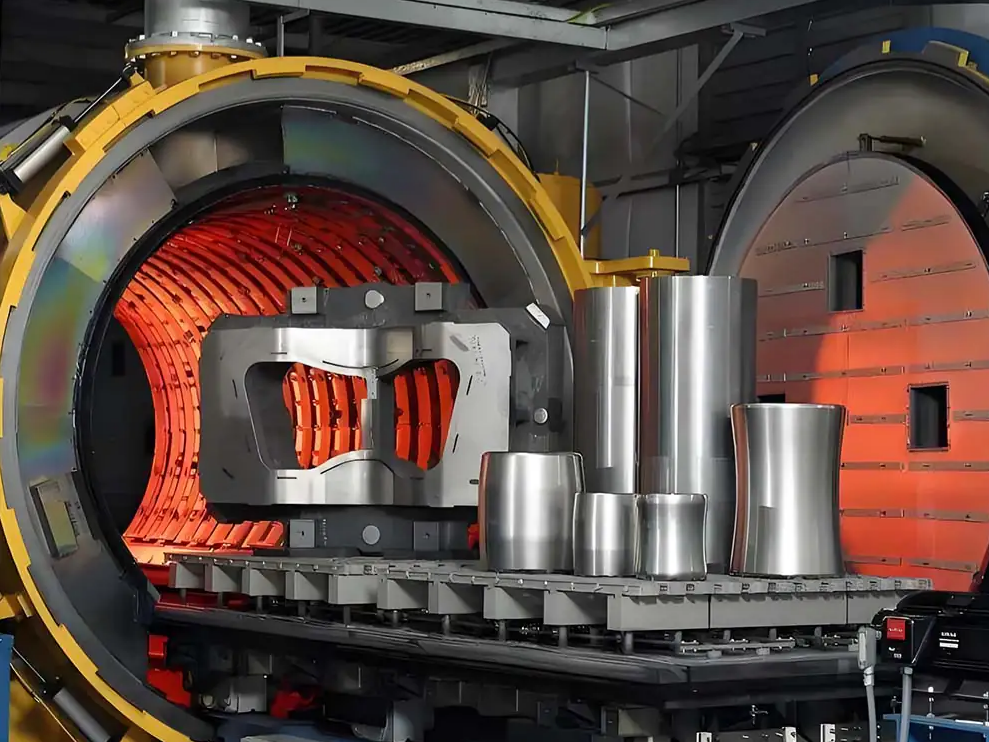

Getting the heat treatment right is absolutely essential if we want to get the most out of steel materials. When done properly, triple tempering around 600 degrees Celsius typically hits that sweet spot between 48 and 52 on the Rockwell scale. This gives us good wear resistance without making the material too brittle. If temperatures drift more than 5 degrees during quenching, though, things start going wrong fast. We see carbides forming where they shouldn't, which breaks down the metal's structure over time. Industry data indicates that using a two stage tempering process actually makes molds last about 30 percent longer because it helps control those grain boundaries better. And let's not forget about keeping furnaces calibrated correctly either. Even small changes in quench rate matter a lot. A mere 1% difference can cut thermal fatigue strength in half, so regular checks are just part of doing business in this field.

Engineering Thermal Management into the Die Casting Mould

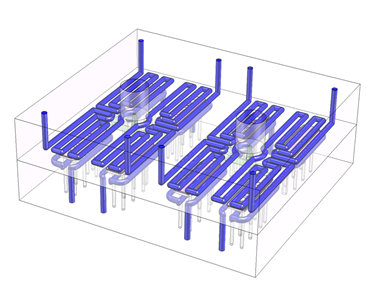

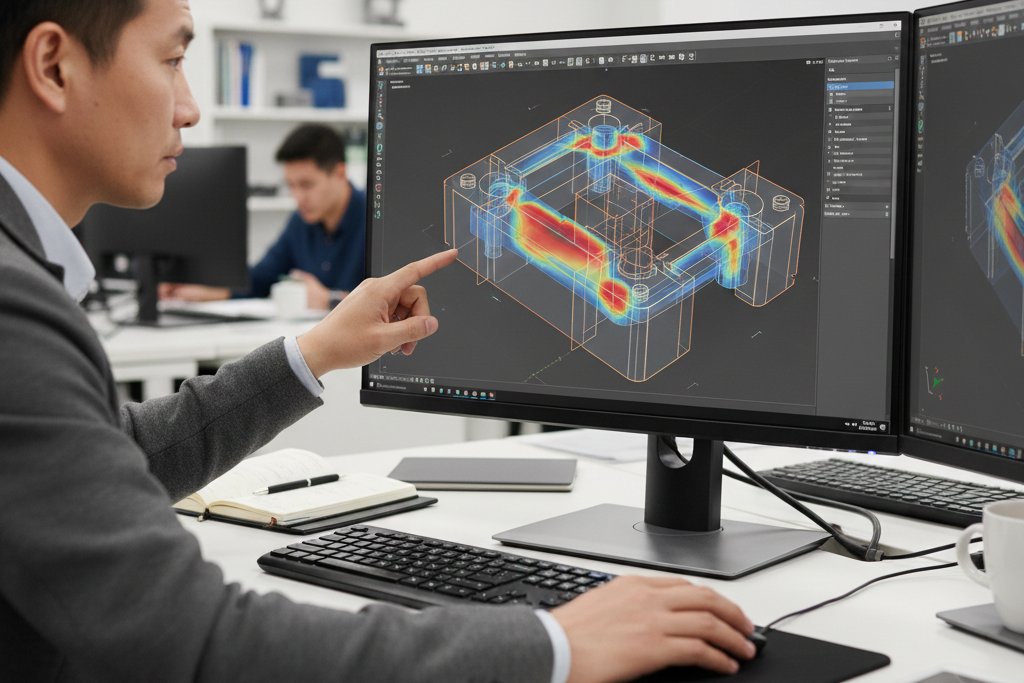

Cooling Channel Layout, Conformal Cooling, and Thermal Gradient Control to Delay Cracking

Getting good thermal control begins with how we design those cooling channels. The old straight line approaches tend to leave hot spots developing, which can cause problems down the road with material stress issues. Enter conformal cooling technology, where 3D printed channels actually match the shape of the mold itself rather than just running in straight lines. What this does is spread out the heat removal much more evenly across the part. We've seen temperature differences drop by around 40% in key areas, which means cracks from heat checking happen later in production cycles. Keeping mold surfaces under 300 degrees Celsius helps prevent warping too. Many shops now combine these advanced cooling designs with sensors that track temperatures in real time, allowing operators to tweak coolant flow as conditions change during manufacturing runs.

Casting Cycle Data Insights: How Temperature Swings Accelerate Thermal Fatigue in High-Volume Die Casting Moulds

When running high volume production lines, it's really the constant heating and cooling that eventually breaks down dies. Every time the temperature swings over 200 degrees Celsius during these cycles, tiny stresses build up inside the tool steel material. After around fifty thousand such cycles, those accumulated stresses show themselves as visible heat check cracks on the surface. Looking at actual shop floor data, we find that when parts cool too quickly - say under fifteen seconds flat - that creates some of the worst thermal shock problems. Manufacturers have found that simply stretching out the cooling time by about twenty percent and adding gradual temperature changes instead of sudden drops can cut down peak thermal stress levels roughly thirty five percent. These kinds of adjustments make a real difference in industries like automotive and electronics manufacturing where how long a die lasts has a direct impact on both production speed and the quality of finished components.

Optimizing Die Casting Mould Geometry for Structural Integrity and Stress Distribution

Critical Design Elements: Fillets, Radii, Draft Angles, and Parting Line Geometry to Minimize Stress Concentrations

Those sharp corners and sudden changes in shape really become problem spots when things expand from heat or get stressed mechanically. They create stress concentrations that just speed up where cracks start forming. When we add those nice rounded edges (at least 1.5mm radius), it spreads out both the heat and mechanical forces over larger areas, which means fewer places for cracks to begin. According to some recent research published in International Journal of Metalcasting back in 2022, aluminum die casting molds with properly sized fillets actually last between 40% to 60% longer compared to ones with sharp edges. Getting those draft angles right too makes a big difference. Keeping them uniform around 1 degree to 3 degrees on each side helps avoid dragging during ejection, which is one of the main reasons surfaces get damaged and dimensions drift over time. Where we place the parting lines matters a lot as well. Putting them away from areas that take the most impact keeps things simpler, and adding convex shapes at contact points cuts down on stress buildup right where the dies meet. All these small design tweaks together help fight against thermal fatigue cracking and can save manufacturers anywhere from $300k up to nearly a million dollars when they need to rebuild automotive molds.

Designing Low-Impact Ejection and Flow Systems for Die Casting Mould Durability

Gating, Venting, and Ejector Layout Strategies to Reduce Warpage, Sinking, and Localized Wear

When gating is properly optimized, molten metal flows into the cavity much smoother, which helps cut down on turbulence problems that lead to internal stress issues, warping parts, and all sorts of surface flaws. Vents positioned at just the right spots help get rid of those pesky trapped gases, so we see less porosity forming, fewer sink marks appearing, and pressure spikes that would otherwise weaken the structure. For the ejector system, balance is key. It needs to spread out force evenly across whatever part is being made. Precision aligned pins work best when they're the correct size too, otherwise parts might distort or certain areas could wear out faster after repeated use. Manufacturers running things at scale really benefit from these kinds of improvements. Studies show around 40 percent less mechanical wear happens with this approach, plus it knocks out many of the usual failure points. Dies last longer obviously, but what matters most is maintaining accurate dimensions even after making tens of thousands of identical parts day after day.

FAQ

Why is H13 tool steel preferred for die casting molds?

H13 tool steel is preferred because it resists thermal fatigue due to its composition of chromium, molybdenum, and vanadium, maintaining stability even at high temperatures around 600 degrees Celsius.

What makes DIN 1.2367 tool steel a good option?

DIN 1.2367 tool steel handles impacts better than H13, making it ideal for situations with strong impacts but fewer thermal cycles.

How can heat treatment improve tool steel performance?

Proper heat treatment, especially triple tempering around 600 degrees Celsius, achieves a balance between hardness and toughness, improving the steel's wear resistance without compromising its structure.

How does conformal cooling enhance die casting molds?

Conformal cooling uses 3D printed cooling channels that match the mold's shape, leading to more even heat removal and reduced thermal stresses and warping.

What is the impact of design elements like fillets on mold longevity?

Design elements like fillets help distribute stress and heat over larger areas, reducing crack initiation points and enhancing the durability of the mold.

Table of Contents

- Selecting and Treating the Right Tool Steel for Die Casting Mould Longevity

- Engineering Thermal Management into the Die Casting Mould

- Optimizing Die Casting Mould Geometry for Structural Integrity and Stress Distribution

- Designing Low-Impact Ejection and Flow Systems for Die Casting Mould Durability

- FAQ