Why CNC Machining Bridges the Gap Between Design Intent and Functional Prototypes

The Fit-Function Failure Challenge: How 68% of Prototypes Miss Validation—and Why CNC Fixes It

Many traditional prototyping approaches create parts that look good on the surface but just don't work when put to the test. According to recent manufacturing reports from 2023, around two thirds of all development projects face this exact problem. CNC machining bridges that gap between appearance and function by turning digital blueprints into physically accurate components through subtractive processes. When compared to 3D printed models which often have structural weaknesses in certain directions, or injection molded samples that need expensive molds upfront, parts made via CNC machines stick much closer to the original design specs. These machines can achieve tolerances as tight as plus or minus 0.005 inches, something that makes a world of difference for engineers testing how things actually perform mechanically, handle heat changes, and fit together properly. For parts that need to bear weight or stress, having consistent materials and precise shapes really matters because even small deviations can lead to big problems down the road.

DFM Integration: How Early CNC Process Collaboration Prevents Costly Iterations

When CNC experts get involved right at the start of design work, it cuts down on revisions by somewhere between 40 and 60 percent because they spot manufacturing issues early on. During these joint engineering meetings, designers actually get immediate input about things like proper draft angles, whether tools can reach certain areas, and if features are too complicated for production before locking in final designs. Working together helps catch problems nobody wants to deal with later, such as thin walls that aren't machined enough leading to vibrations, or sharp inside corners that require extra EDM work, plus threads that don't meet standard specs and slow everything down. Getting CAD models aligned with what machines can do from day one saves money too. The 2024 Prototyping Benchmark Report shows companies typically spend around $7,500 each time they have to revise a design. Plus, this teamwork often finds ways to combine multiple parts into one single CNC component, which makes structures stronger overall while cutting down on the number of separate pieces needed.

Tackling Geometric and Tolerance Barriers in CNC Prototyping

Complexity vs. Precision: Managing Organic Shapes and Sub-0.005" Tolerances Efficiently

Getting those complex shapes right while keeping tolerances at the micron level continues to be one of the big headaches in CNC prototyping work. Modern 5 axis machines definitely help with creating all sorts of complicated curves, but holding onto that sub 0.005 inch precision over curved areas still takes some serious planning. When we focus really tight tolerances just on the parts that actually need them (around plus or minus 0.01 mm) and let other areas have a bit more leeway, it saves roughly 30% of machining time without hurting how well the part works. The way we adjust tool paths helps reduce bending issues when working on thin walls, and special cutting techniques called trochoidal milling keep things accurate even in those tricky deep pockets. By being selective about where we apply this strict precision, we avoid blowing up costs while making sure the important measurements still pass quality checks.

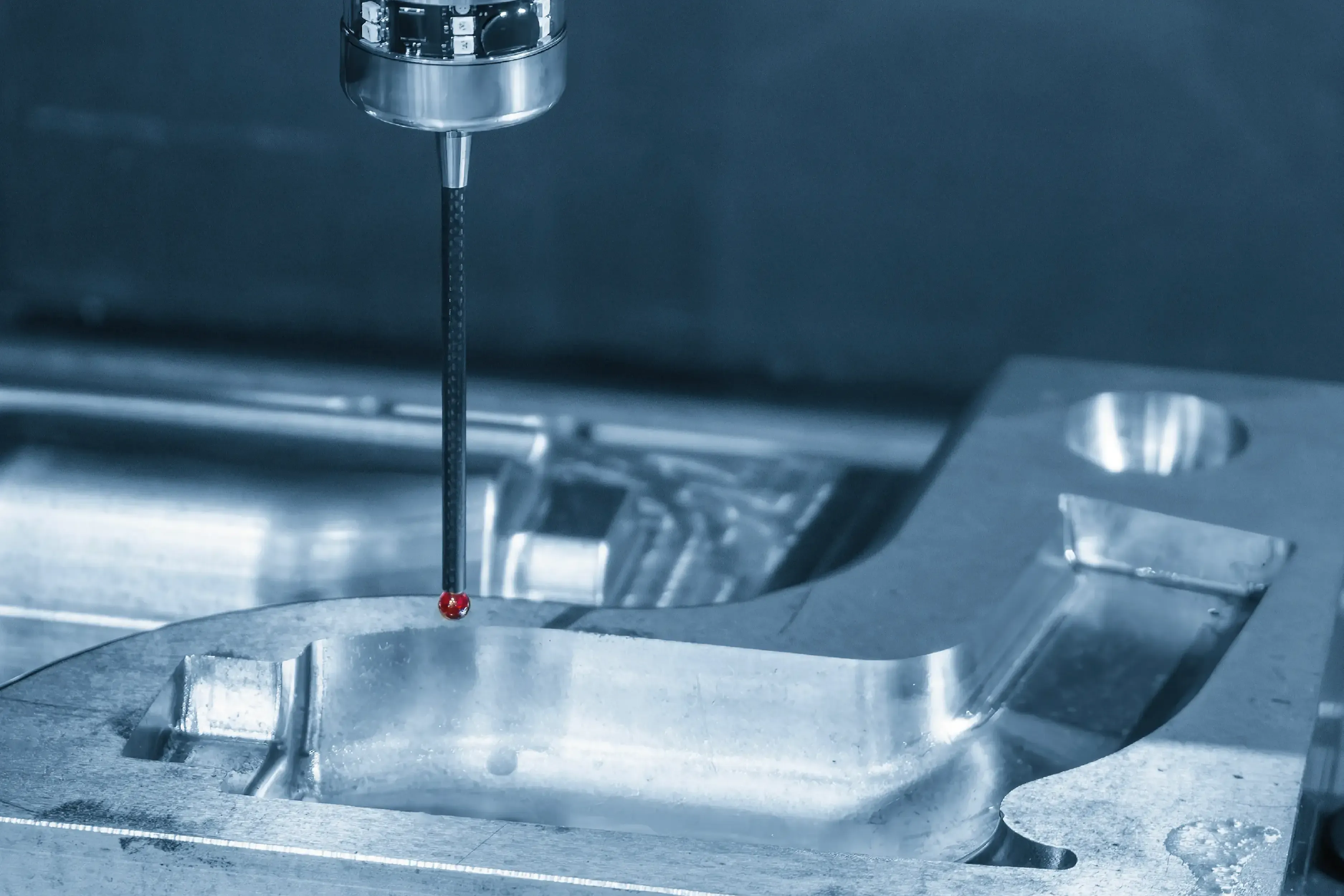

Hybrid Metrology: Ensuring Accuracy with On-Machine Probing and Laser Scanning

When it comes to checking complex prototypes, manufacturers need to mix different measurement techniques. On-machine probing allows technicians to verify important reference points right after machining happens, which catches mistakes as they occur rather than waiting until later stages. Some factories report around 45% less rework thanks to these immediate corrections. Next up is laser scanning that grabs complete shape details at an impressive rate of about 50 thousand points per second. These scans get compared directly to CAD designs following those GD&T standards everyone talks about but not many fully understand. By looking at both size measurements and actual shapes, engineers can spot problems such as warping in delicate parts long before anything gets approved for production. All this information flows together into what's called a digital twin, making it much easier to generate those required first article inspection reports without missing anything crucial.

Smart Material Selection for CNC Prototyping: Performance, Fidelity, and Machinability

Material choice directly impacts prototype functionality and manufacturing efficiency. Balancing thermal, mechanical, and structural properties prevents costly redesigns while ensuring end-use fidelity.

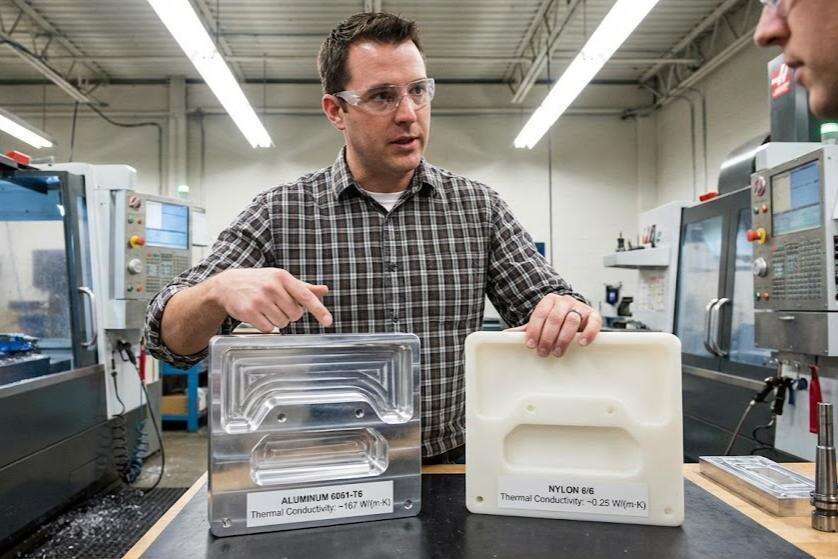

Functional Tradeoffs: When Nylon’s Thermal Behavior Outperforms Aluminum—And When It Doesn’t

The fact that nylon doesn't conduct much heat (around 0.25 W/mK) makes it great for parts that need insulation, especially when we're talking about things like electronic enclosures where keeping heat inside matters a lot. Aluminum tells a different story altogether since it conducts heat so well at about 205 W/mK, which is exactly why it's used in those cooling fins for power supplies and other high heat applications. Once temperatures get above roughly 150 degrees Celsius though, nylon starts to warp while aluminum stays strong and stable. When looking at places with harsh chemicals, say in some sensor housing applications, nylon holds up much better against breakdown than aluminum does because metal tends to rust away pretty quickly there. All these factors show that picking materials isn't just about finding something cheap or tough enough, but matching what the part needs to do with the conditions it will face day after day in real-world situations.

The Machinability Index: A Practical Framework for Material Choice in CNC Prototyping

The machinability index quantifies how easily materials respond to cutting tools, integrating key factors:

| Factor | High Machinability (e.g., 6061 Aluminum) | Low Machinability (e.g., 304 Stainless Steel) |

|---|---|---|

| Tool Wear | Minimal | Accelerated (50% faster) |

| Surface Finish | Smooth (Ra ≤ 0.8 μm) | Rough (Ra ≥ 3.2 μm) |

| Production Speed | 30% faster | Delays from frequent tool changes |

This framework guides practical decisions: brass or POM for complex geometries requiring tight tolerances; titanium alloys reserved for high-strength aerospace applications. Integrating the machinability index early in design reduces CNC machining costs by 22%, per the Journal of Manufacturing Processes (2023).

Accelerating CNC Prototyping Without Compromising Quality

Getting the right balance between speed and precision is really important when developing prototypes. Old school methods usually mean companies have to choose between getting things done fast or making sure they're good quality. Modern CNC machining changes this equation thanks to those super fast spindles spinning over 60k RPM and smart tool path optimizations. These machines can knock out iterations 40 to 60 percent quicker without sacrificing accuracy down at the micron level. What this means for manufacturers is no longer having to rely on expensive molds which cuts setup time around 80%. Now designers can go straight from CAD files to actual parts for testing right away. The real magic happens behind the scenes though. Advanced monitoring tech keeps an eye on everything during these rapid operations. Vibration sensors work alongside thermal compensation systems to hold tight tolerances within plus or minus 0.0005 inches even when running at full tilt. Most shops report that about 90 something percent of their prototypes pass validation tests the first time through according to recent industry stats from last year.

Key acceleration strategies include:

- Adaptive Machining: Dynamically adjusting feed rates based on real-time material feedback

- Lights-Out Automation: Unattended operations enabled by automated pallet changers

- Toolpath Optimization: Reducing non-cutting movements by 45% through AI-driven algorithms

This integrated approach ensures production-grade material properties and surface finishes in prototypes—slashing development timelines without sacrificing performance verification.

Frequently Asked Questions

Why is CNC machining preferred over 3D printing for prototypes? CNC machining creates parts that adhere closely to original design specifications offering higher structural integrity and tolerance levels compared to 3D printing which can have directional weaknesses.

What is the role of DFM in CNC prototyping? Design for Manufacturing (DFM) collaboration helps ensure that designs are optimized for the machining process early on, preventing costly iterations and revisions during prototyping.

How does material choice affect CNC prototyping? Material selection impacts the performance and manufacturing efficiency of prototypes by balancing thermal, mechanical, and structural properties suited to the prototype's end use.

What are hybrid metrology techniques used in CNC prototyping? Hybrid metrology combines on-machine probing and laser scanning to ensure accuracy in complex prototypes, enabling immediate corrections and comprehensive shape verification.