Dec 22,2025

0

A cikin sayen yin abubuwa a yau, akwai tsari mai kama da kwayoyin iko da zure mai sauya metal na tura zuwa kayayyaki mai girman inganci da kwayar da za'a iya samuwa shi ne a hanya mai sekondi iri dekada biyu—wannan tsari shine die casting . Daga kayan injin na mota da kayan laptop zuwa kayan wasan gida da kayan iko mai zurfi, tsarin baki yana iya amfani da mahimmancin a cikin wasan gona.

Yaushe ya ke aiki tsarin baki? Wace ne izwarsa bisa ga wasan tsarin baki? Da ma shin gaskiyoyensa da karamayensu? Wannan labarin yana ba da bayani mai zurfi da kwayar a karkashin teknologin tsarin baki, ta don taimaka wajen fahimtar saboda ya zama babban batutuwa a cikin sayen yin abubuwa na yau.

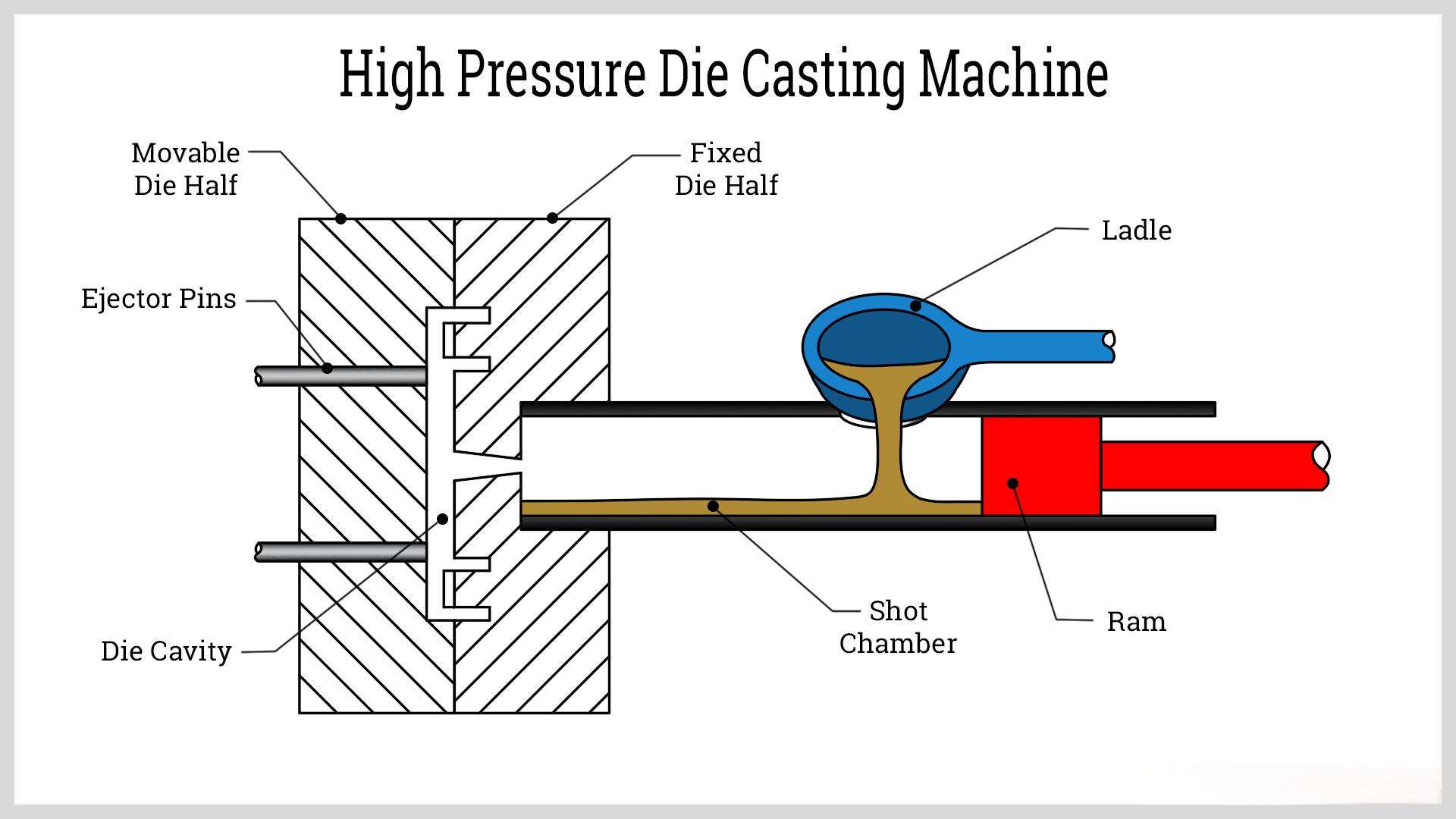

Die casting , kuma ana kiran shi tsarin baki mai gurbin , ita ce ƙwayoyin da ke tsauraran wanda zai halitta ko kuma halittar mutum yana shiga cikin tafal ƙwayoyin (die) a sauƙi mai zurfi da zurfin dabin , wanda a shigarwa zai barzawa don samar da ƙwayoyin da aka gama.

Maimakon tsarin die casting suna da mai sharhi ta fiye da sauƙi mai zurfin shiga . Dabin na shiga zai iya tabbataru daga wasu megapascals (MPa) zuwa karkashin MPa, yayin da sauƙin shiga halitta yana daga 0.5 zuwa 120 m/s . Dukiyen proses shiga zai dauki kawai 0.01 zuwa 0.03 seconds .

Wadannan sharuddan zurfin kayan aiki clearly suka kafa farkon farko na die casting daga sauran hanyoyin ƙwayoyin, kuma suna tsutsun bayani game da ingancin inganci da kwaliti na fasaha.

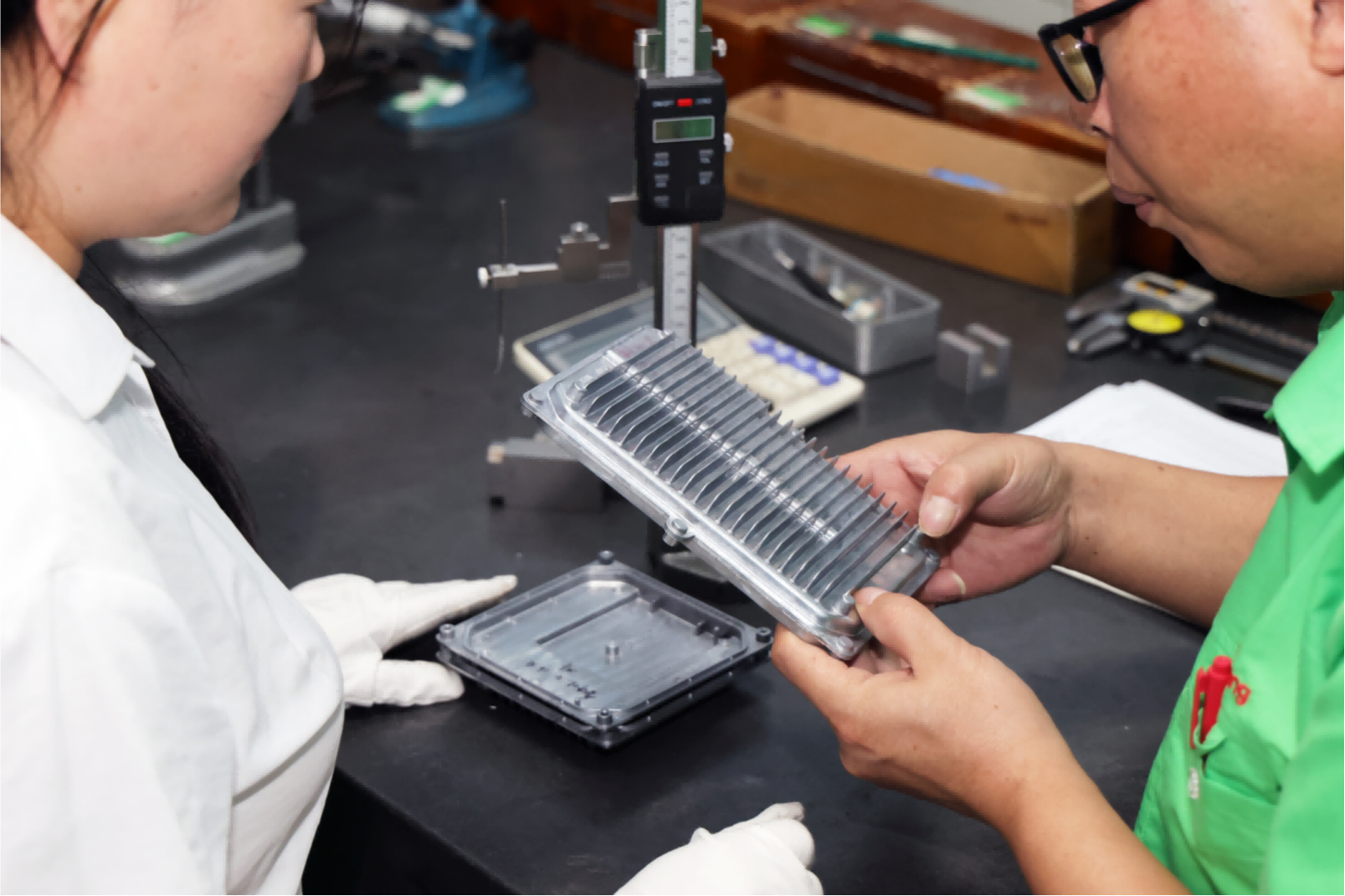

Zanzuwar yan zuwa zai sami daidaiton girman ta IT11 –IT13 , tare da alkarfin nisa mai ƙaranci. Zafuwa suna bukatar saukin gyara ko wala baya, kuma za su iya haɗawa direta, yayin da ke bamu daidaiton yanki.

Tare da tsarin production mai dacewa da shape, amfani da abubuwa yana wucewa 60–80%, yayin da amfani da blank na iya ruwa 90%, ta kara gajin matsari da kuma kudaden biyan kuɗi na abubuwa.

Anfani mai goyon yawa wajen yin abubuwan da kayan aiki masu girman mabda’i, shararon tsohuwa, da kuma katunan sanyi. Babban sararin katunan zai iya kasancewa kamar 0.3 mm ga alurashi na zinc da 0.5 mm ga alurashi na aluminum .

Abubuwan daga cikin metal ko ba su ne (kamar taggare tsabar) suna iya haɗawa a cikin abubuwan bayan cin zarafi, yayin taimaka wajen sauya tsarin abubuwa kuma kara kudaden adduwa.

Kayan aiki mai zurfi yayin rage-rage yaƙe ta hanyar cin zarafi ya fara shiga kusan kwayoyin madai da kewayon zurfi, wanda ke kawo zuwa iyaka mai amfani, kwayon zurfi, kewayon haske, da kuma kewayon karbarwa.

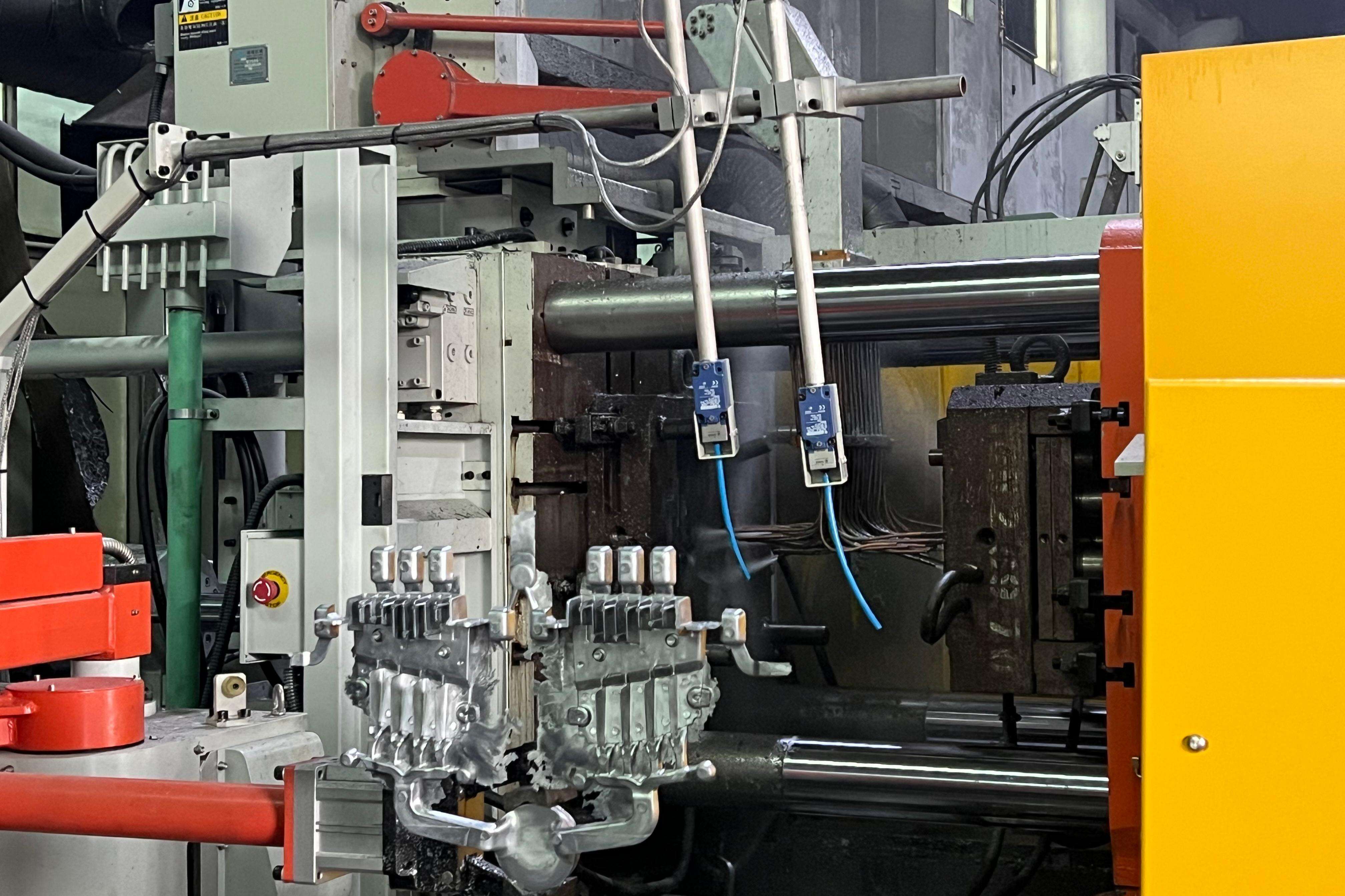

Tsawon kuskuren die casting suna mahiraba kuma suna daidai ga automation, sai dai suke tsada hanyar yin production mai girma. Misali, mesin mai tsauri na die casting za ta iya amsawa 3,000–7,000 shot per shift .

Saboda kyakkyawan sauƙin cirewa, zamuwar abubuwa a cikin chamber zai bisa wuce shiga shigarwa, zai haɗa da internal porosity. Don haka, abubuwan die cast masu alaƙa ba su dace don yin amfani da shiga wuya ko a temperature mai hanna.

Abubuwan die casting da mesini suna buƙatar investiment mai yawa a baya, sai dai sun tsada iyakar biyan kuɗi game da tsarin production mai ƙarami.

Girman casting mai ƙarshe ya kasance ya dararci ta kyakkyawan gurji na mesini da girman mold, sai dai ya dararci imkanin yin abubuwa mai girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman girman gir......

Saboda tsawon gini na abubuwan da ke samun sauri, ya kasance wani hanyar yin amfani da alloys alloys mai zurfi , kamar misalan aluminum, zinc, magnesium, da alloys na copper. Yankin ferrous metals har ma yanzu yana cikin yanayin bincike da gwaji.

Wani tsari na iya hannun yin amfanin die casting yana daga cikin wasu matakan nan:

1. Yanke tsaron die - Yanke tsaron die zuwa tsawon gini na aiki

2. Lubrication na die - Buga abubuwan fara hada da lubrication akan juyawa ta die

3. Kullewa ta die - Haɗin abubuwan da ke tsaye da abubuwan da suka shiga

4. Ruba mai - Shigo da zafi mai nari a cikin gida mai shot

5. Ijaɓa da kiyama - Ijaɓa mai zuwa cikin cavity ta hanyar kwanciyar yawa da pressure, sannan kiyama ta hanyar pressure

6. Tushen dabara da nuni - Tushen dabara da nuniwar abubuwa

7. Guzuru da tabbata - Cirewa da jeri da overflows, sannan tabbatar da kwaliti

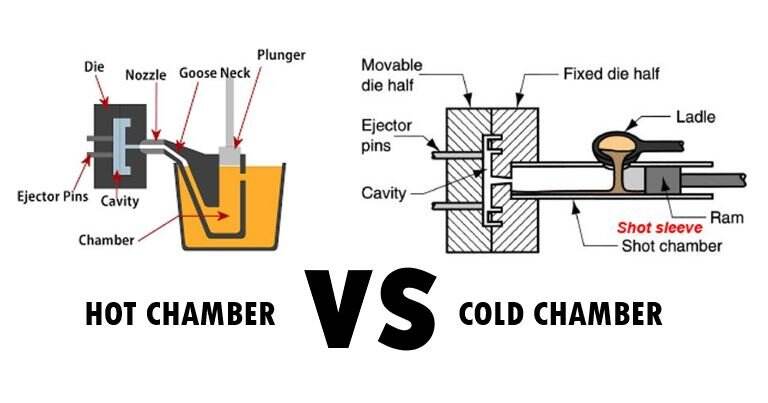

Mashinun kashi na die suna 'yan kasuwa mai mahimmacin aiki a cikin aiki kuma yau da kullum ana rarrabewa su zuwa sauyi biyu masu mahimmanci:

Ka'idar aiki

Chamber na shot tare da furnace na gona, wanda ya tsai ne a cikin metal na tagu.

Tsataye

Ayyukan Aikin Babban

Ana amfani da ita kamar yawa wajen alloyoyin da kele shigogar tagu misali: zink, tin, da alloyoyin sarai.

A cikin wasan karamar wani abu, kayan na'ura tausayi daga furushe zuwa girman na'urar, kuma an gurji na'urar tauraro a cikin girma wajen kowa da kowa.

Wasan karamar ruwa ta hanyar tsakiya

Wasan karamar ruwa ta hanyar sama

Mashinun kashi mai tsushe a cikin tsushe

An fara kashi a gashtahun 19s da aka yi wajen production na type na sarrafa. Bayan karshen sa diga fi karni, kusan wasu albabbar sun fito:

Mashinun kashi na yau suna zamawa mai girma, mai zurfi, da mai kontin komputa, kuma sun ba da damar duba lokaci kusan da production mai sauƙi.

Don hana batun halayyin, teknologijar kamar vacuum die casting , oxygen-assisted die casting , da kuma squeeze die casting sun kafa, ta wayar da aka samu a cikin kwaliti na tasowa kuma ta ba da damar yadda za'a iya amfani da tasowar gudu.

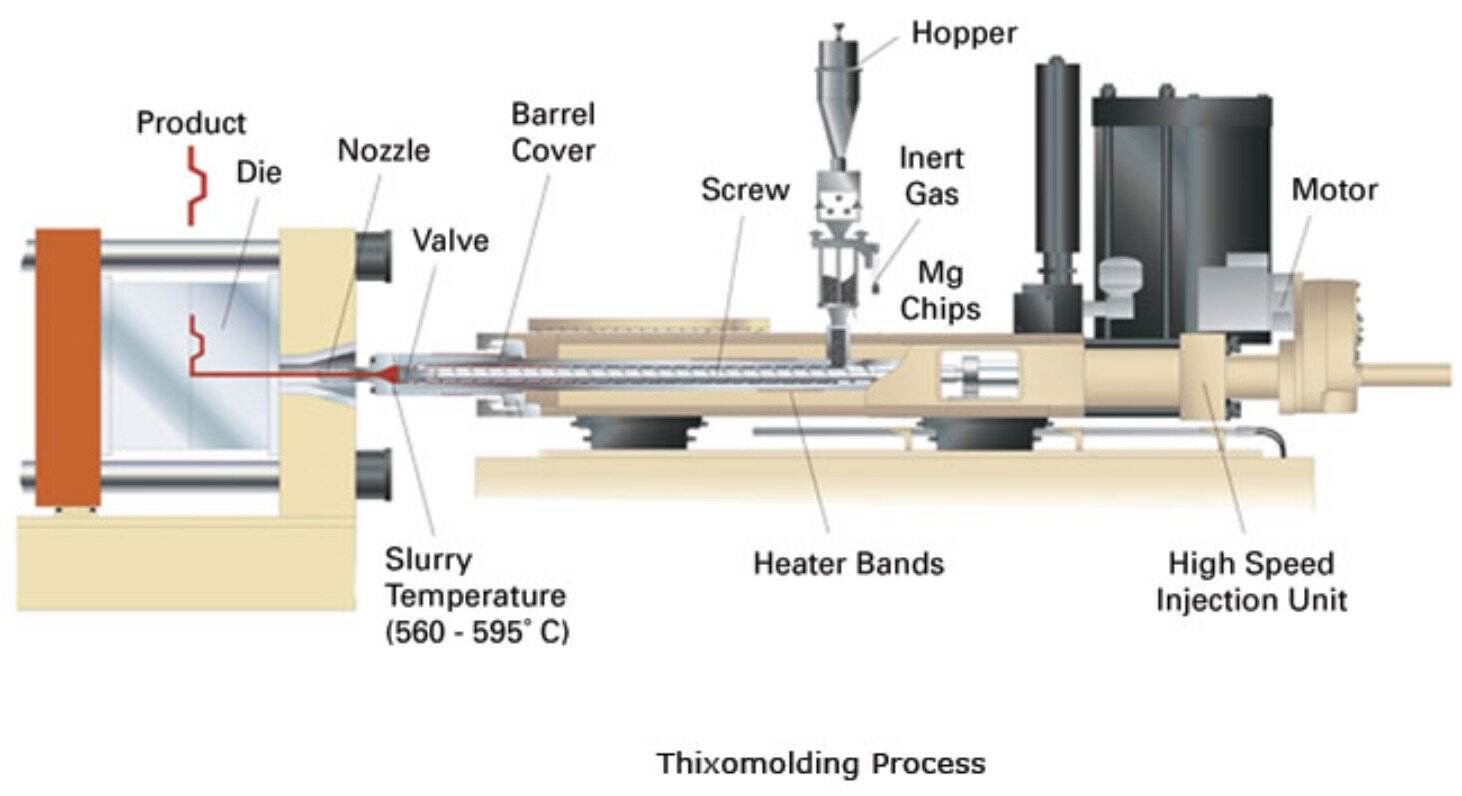

Semi-solid die casting amfani ne da sarayyar wuta a halin semi-solid, ta kama gas karami da shrinkage yayin da ta inganta alamu na makani. Wataƙila ita ce a matsayin teknoloji na sabon kafin tsarin wutar wuta.

Tare da ci gaba a kan abubuwan da ke nuna madaidaici (kamar alloys based on molybdenum da tungsten), sun dace a cikin tasowa ta ferrous metals, kamar cast iron da steel.

An samun farko daga cincinna mai tsauri zuwa abubuwan kafa da ake amfani da su a cikin kayan uku na otomatik da kayan uku na sama, wadanda ke amfani da suna.

Die casting ita ce daga cikin yankin ƙirƙira abubuwa mai nauyi na izzi wadda take karuwa sosai kuma ana amfani da ita a karkashin yanayi masu zuwa:

Yanayin otomatik da maɓallan mota suna taka kamar 70–80%daga kuma a cikin matakan die casting. Wasu yanayin muhimmi sune: kayan iko, kayan aiki, alajiji, kayan gida, kayan zuciya, taliƙaɗa, da sayarwa.

Abubuwan die cast sun takawa daga cincinna suka fi qalil gramu zuwa cincinna alwuminum suka fi 50 kg , kamar kayan injin, sarufan silinda, juyuka, kujera, ilimin ginya, da abubuwan da aka yi sadarwa.

A cikin alloyos na non-ferrous die cast:

Kamar wani teknolojin sadarwa mai tsofaffa ta kama da sadarwa mai dandalin, yawa, da kuma mai saukin gyara dandalin, yawa, da saukin gyara , ya zama babban tsari na tsaron nishadi a zaman lafiya—masu kan sasannun otomitiva. Dandalinsa a cikin sauki, inganci, da haɗin abubuwan da yawa suna taka rawar mahimmanci a cikin sadarwar wanka mata, kuskuren kudaden, da ingancin aikace-aikacen bayanin.

Ne maƙa duk da masalolin kamata porosity da kudaden mafi girma na kayan aikin, karin ci gaba a cikin vacuum die casting, semi-solid forming, kayan aiki na mold, da teknolojin uwar samun maye suna bude sauƙunan sabon. A halin zuwa, yayin da bukatun dandalin, wanka mata, da saukin production suna taka, die casting zai taka rawar maimakon bayan bayan a cikin ayyukan samar da amincewa da mafi girma.