Dec 22,2025

0

In modern manufacturing, there is a highly efficient and precise metal forming process that can transform molten metal into complex, dimensionally accurate parts in just a few seconds—this process is die casting. From automotive engine blocks and laptop housings to household appliance components and precision instrument parts, die casting plays a critical role across industries.

How does die casting work? What makes it unique compared with other casting methods? And what are its advantages and limitations? This article provides a clear and professional overview of die casting technology, helping you understand why it has become a cornerstone of modern metal manufacturing.

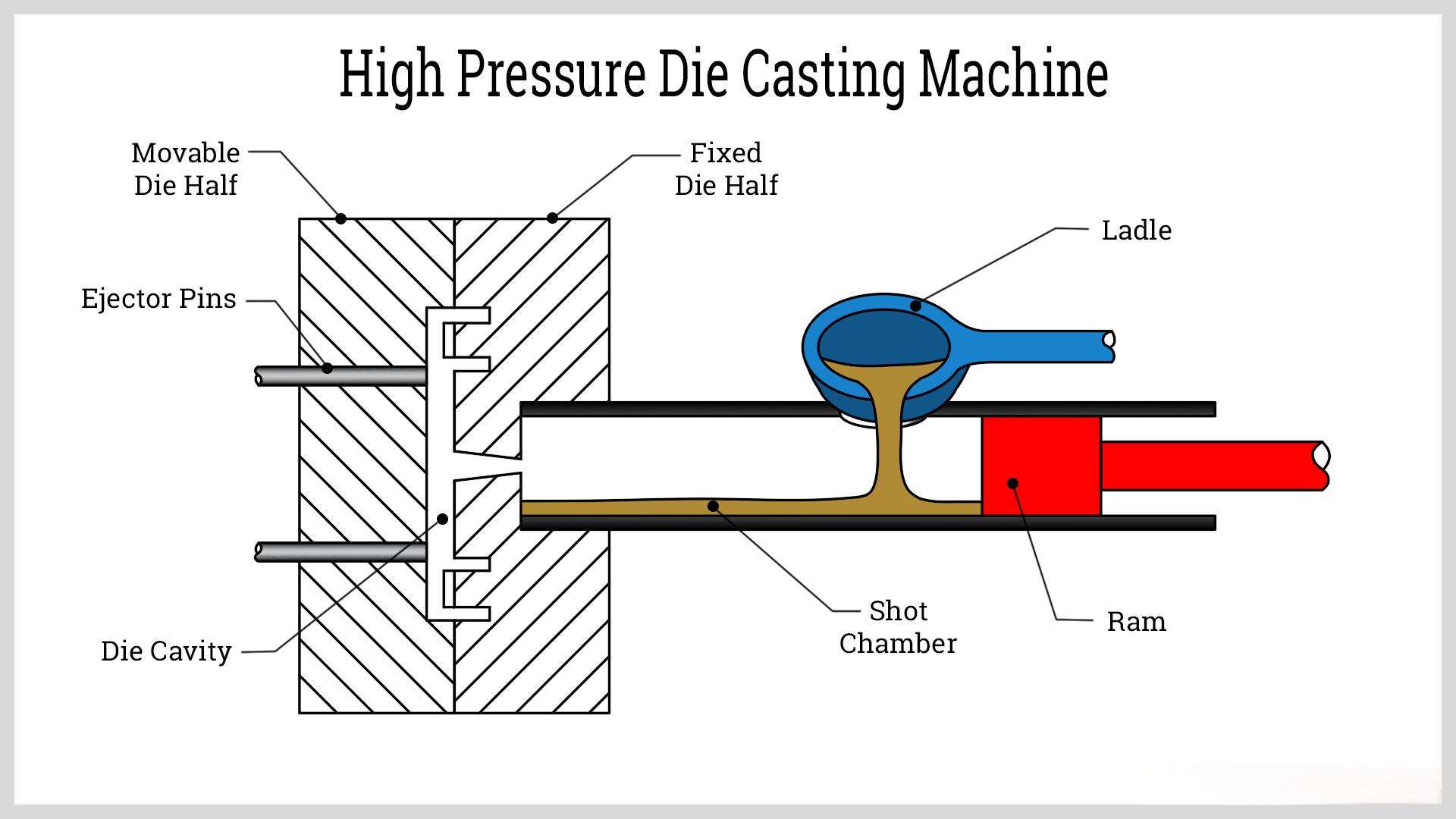

Die casting, also known as pressure die casting, is a precision casting process in which molten or semi-molten metal is injected into a metal mold (die) at high speed and high pressure, where it rapidly solidifies to form a finished casting.

The most distinctive characteristics of die casting are high pressure and high injection speed. The injection pressure can range from several megapascals (MPa) to hundreds of MPa, while metal filling speeds typically range from 0.5 to 120 m/s. The entire filling process usually takes only 0.01 to 0.03 seconds.

These extreme process conditions clearly differentiate die casting from other casting methods and are the foundation for its superior dimensional accuracy and surface quality.

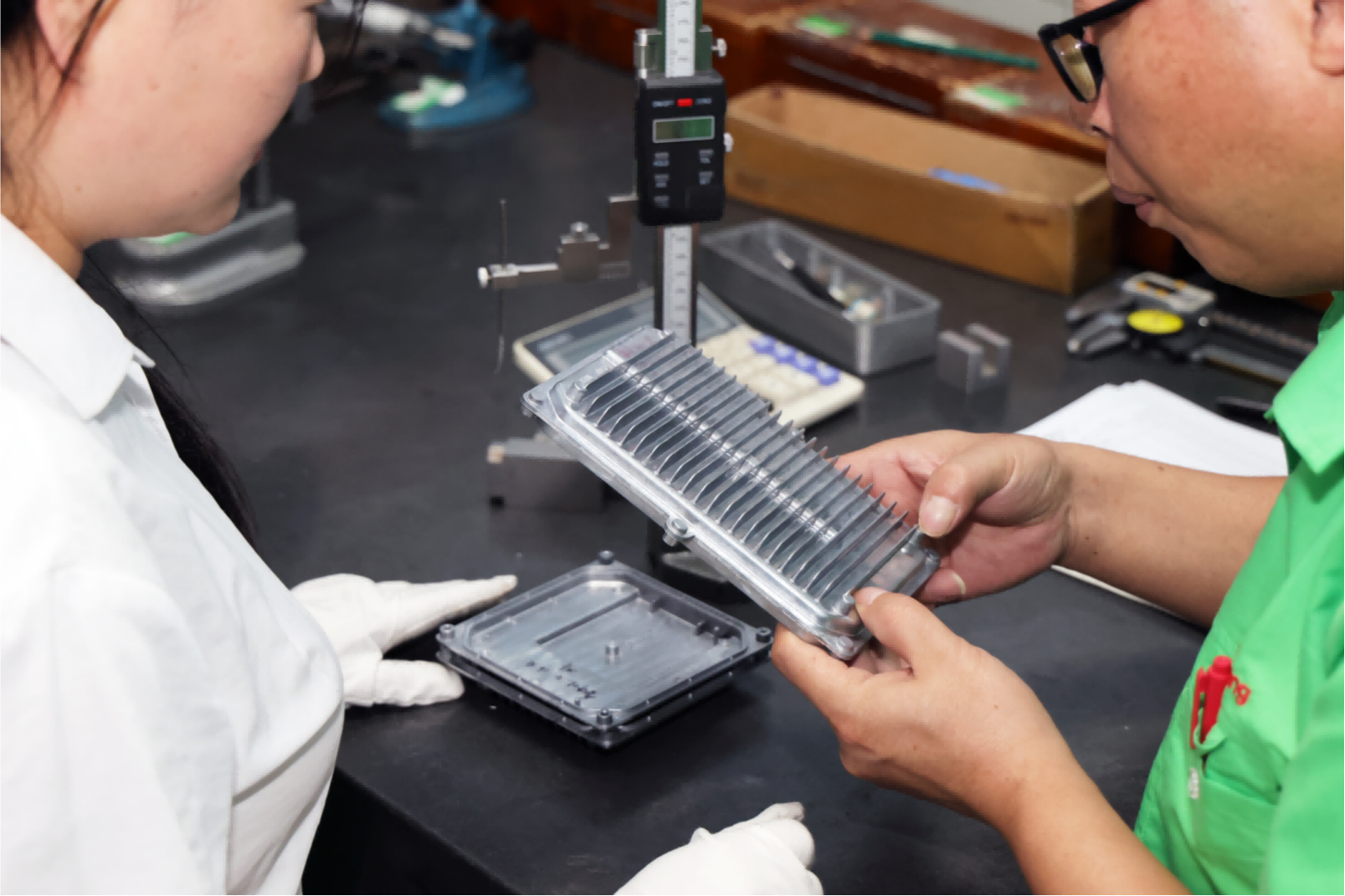

Die cast parts typically achieve dimensional tolerances of IT11–IT13, with low surface roughness. Parts often require little to no secondary machining and can be assembled directly, ensuring excellent interchangeability.

Thanks to near-net-shape production, material utilization usually reaches 60–80%, while blank utilization can exceed 90%, significantly reducing material waste and machining costs.

Die casting is ideal for manufacturing components with complex geometries, sharp contours, and thin walls. Minimum wall thickness can be as low as 0.3 mm for zinc alloys and 0.5 mm for aluminum alloys.

Metal or non-metal inserts (such as threaded inserts) can be cast directly into the part, simplifying product design and reducing assembly steps.

Rapid solidification under pressure produces fine grain structures and high density, resulting in improved strength, hardness, wear resistance, and corrosion resistance.

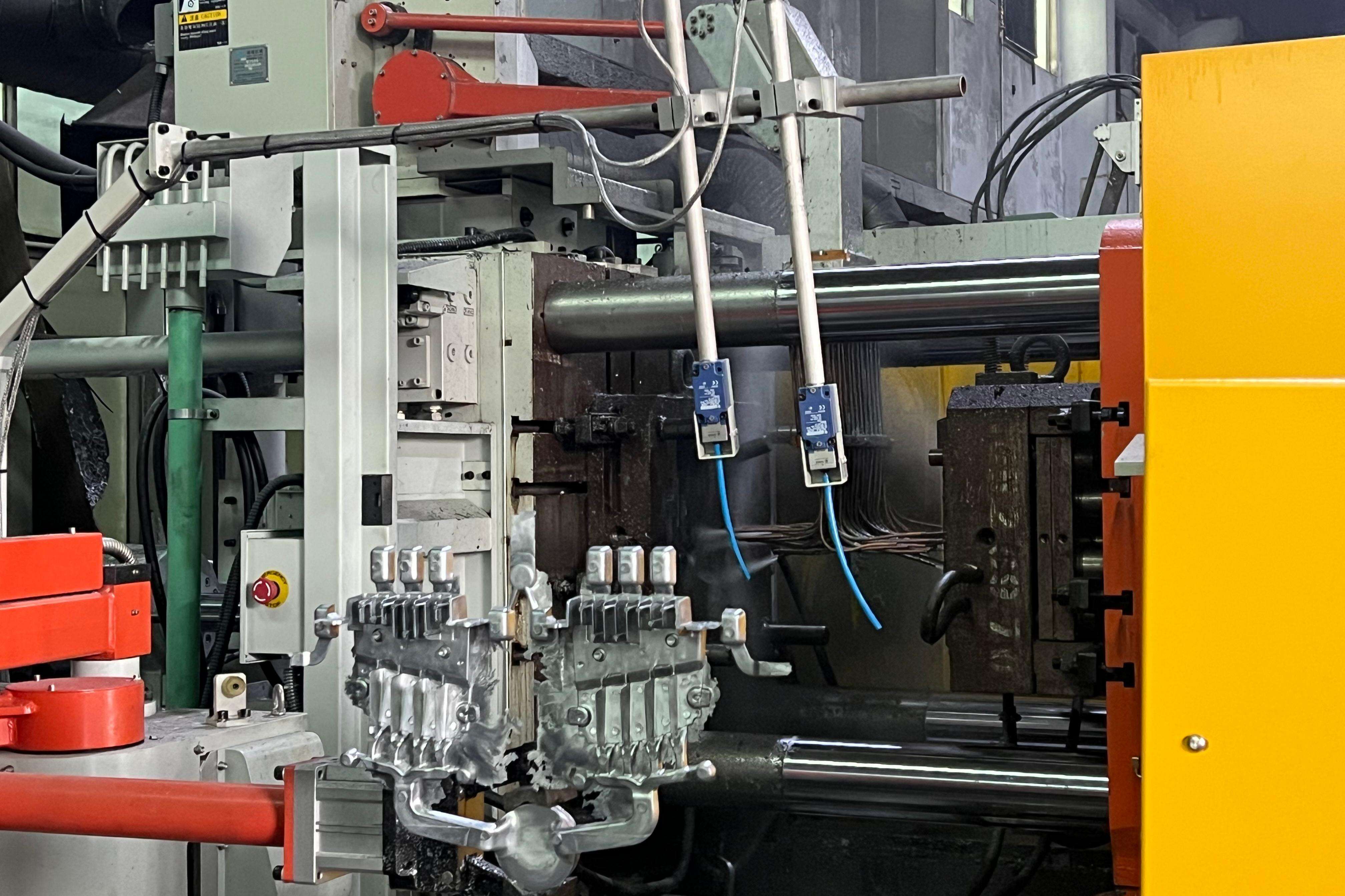

Die casting cycles are very short and well-suited for automation, making the process ideal for high-volume production. For example, a small hot-chamber die casting machine can perform 3,000–7,000 shots per shift.

Due to the extremely fast filling speed, air inside the die cavity may not be fully expelled, leading to internal porosity. As a result, conventional die cast parts are generally not suitable for heat treatment or high-temperature service.

Die casting molds and machines require significant upfront investment, making the process less economical for low-volume production.

The maximum casting size is restricted by machine clamping force and mold dimensions, limiting the feasibility of very large components.

Due to mold material temperature resistance, die casting is primarily used for non-ferrous alloys, such as aluminum, zinc, magnesium, and copper alloys. Die casting of ferrous metals is still largely in the research and experimental stage.

A typical die casting production process includes the following steps:

1. Die preheating - Heating the die to its operating temperature

2. Die lubrication - Spraying release and lubrication agents onto the die cavity

3. Die closing - Clamping the moving and fixed die halves

4. Metal pouring - Introducing molten metal into the shot chamber

5. Injection and solidification - Injecting metal into the cavity at high speed and pressure, then solidifying under pressure

6. Die opening and ejection - Opening the die and ejecting the casting

7. Trimming and inspection - Removing runners and overflows, followed by quality inspection

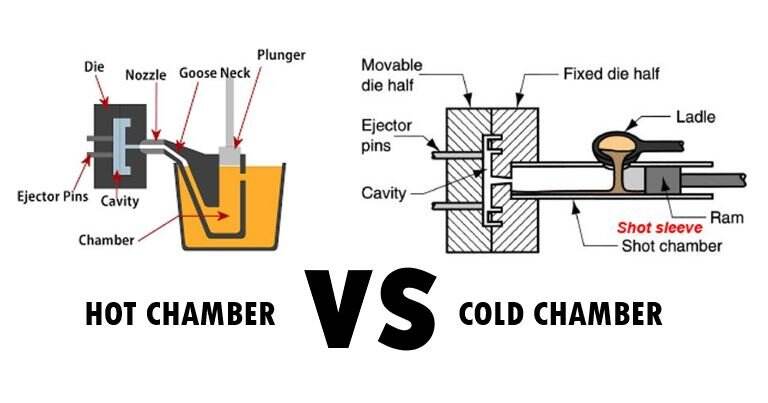

Die casting machines are the core equipment of the process and are generally divided into two main categories:

Working principle

The shot chamber is integrated with the holding furnace and immersed directly in molten metal.

Characteristics

Typical applications

Mainly used for low-melting-point alloys such as zinc, tin, and lead alloys.

In cold-chamber machines, the shot chamber is separated from the melting furnace, and molten metal is ladled into the chamber for each shot.

Horizontal cold-chamber die casting machines

Vertical cold-chamber die casting machines

Fully vertical die casting machines

Die casting originated in the early 19th century in the printing industry for lead type production. Over more than a century of development, several clear trends have emerged:

Modern die casting machines are increasingly large-scale, series-based, and computer-controlled, enabling real-time monitoring and automated production.

To address porosity issues, technologies such as vacuum die casting, oxygen-assisted die casting, and squeeze die casting have been developed, significantly improving casting density and enabling heat treatment.

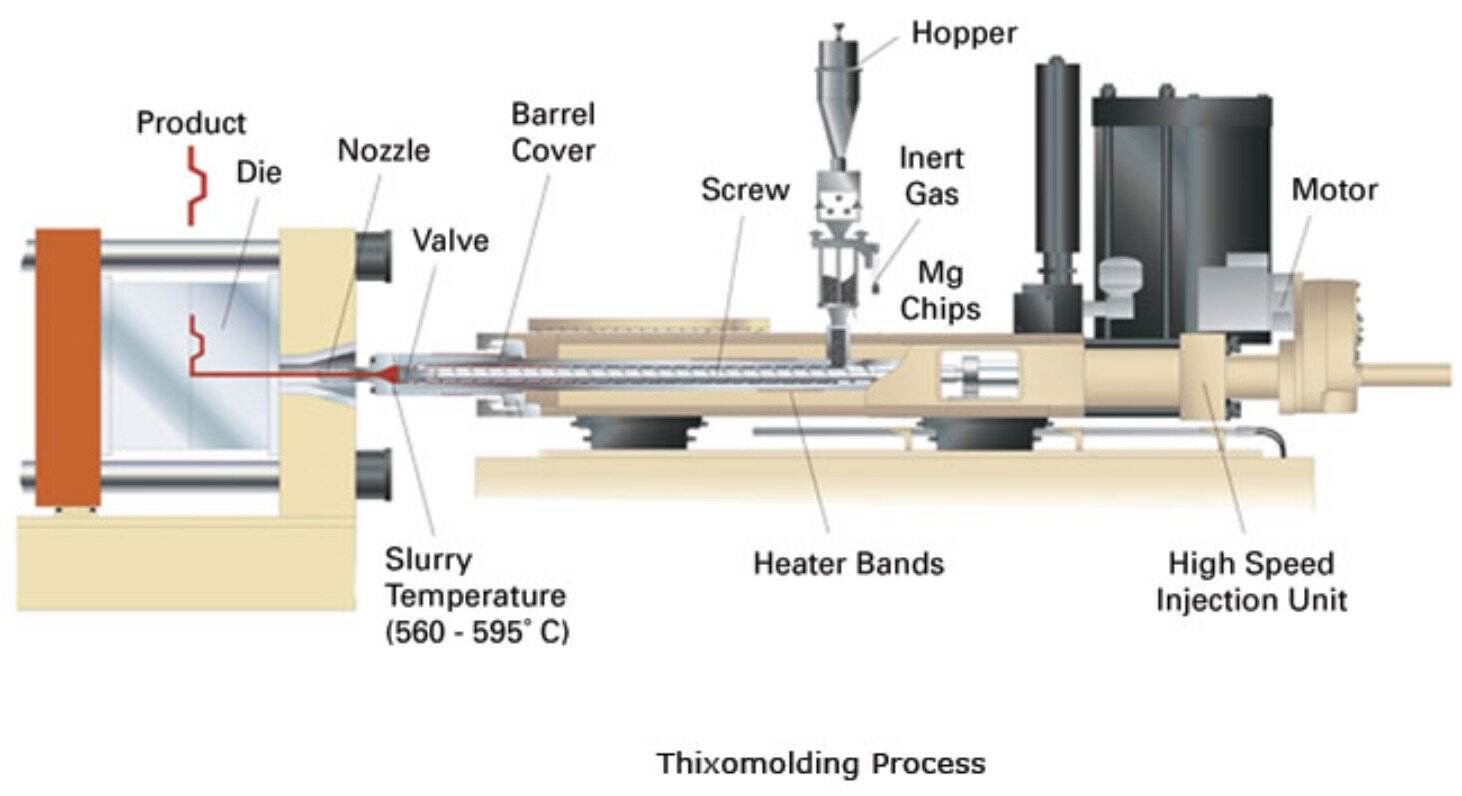

Semi-solid die casting uses metal slurry in a semi-solid state, reducing gas entrapment and shrinkage while improving mechanical properties. It is widely regarded as a next-generation metal forming technology.

With advancements in mold materials (such as molybdenum- and tungsten-based alloys), progress has been made in die casting ferrous metals, including cast iron and steel.

Die casting has evolved from simple components to high-performance parts used in automotive structural components and aerospace applications.

Die casting is one of the fastest-growing precision metal forming processes and is widely used across industries:

The automotive and motorcycle industries account for approximately 70–80% of total die casting production. Other key sectors include instrumentation, industrial equipment, household appliances, agricultural machinery, telecommunications, and transportation.

Die cast parts range from small components weighing only a few grams to large aluminum castings weighing up to 50 kg, including engine blocks, cylinder heads, housings, brackets, wheels, and decorative parts.

Among non-ferrous die cast alloys:

As an advanced metal forming technology combining high pressure, high speed, and high precision, die casting has become an indispensable pillar of modern manufacturing—especially in the automotive industry. Its advantages in efficiency, accuracy, and complex part integration play a crucial role in lightweight design, cost reduction, and product performance improvement.

Although challenges such as porosity and high tooling costs remain, continuous advancements in vacuum die casting, semi-solid forming, mold materials, and machine technology are unlocking new potential. Looking ahead, as demands for higher performance, lighter weight, and greater production efficiency continue to rise, die casting will play an increasingly vital role in advanced and high-end manufacturing applications.