Discover Apple’s heat-forged aluminum unibody on iPhone 17 Pro and see how CNC machining enhances performance and design

Introduction

When Apple unveiled the heat-forged aluminum unibody design of the iPhone 17 Pro at its Fall 2025 event, the spotlight once again turned to groundbreaking innovations in material processing. As a professional CNC precision machining and mold manufacturing service provider, we take a closer look at this advanced process—from principles and workflow to industry applications—to reveal how it redefines the standards of high-end manufacturing.

What Is Heat-Forged Aluminum Unibody?

Heat forging is a process in which aluminum alloys are plastically deformed at elevated temperatures, producing an integrated and complex part in a single step. Unlike traditional multi-part assembly, this method achieves one-piece structural integrity, fundamentally transforming the way metal components are manufactured.

For 7075 aluminum alloy, the typical forging temperature range is 370–480°C. Within this range, material ductility increases and cracking resistance improves, enabling the alloy to fully fill intricate mold cavities.

Apple’s choice of this process is deliberate:

After forging, tensile strength reaches 300–400 MPa with elongation of 10–20%, striking a balance between strength and toughness.

The unibody construction eliminates weak joints found in conventional assemblies, increasing rigidity by about 40%, while freeing up more internal space for a larger battery without sacrificing a slim form factor.

Heat Forging vs. Other Processes

To understand its advantages, let’s compare heat forging with cold forging and die casting.

Heat Forging vs. Cold Forging

Cold forging at room temperature achieves higher precision and tensile strength (400–500 MPa+), but with limited ductility, making complex geometries difficult.

Heat forging improves material flow under high temperature, enabling greater deformation and intricate designs—ideal for smartphone housings that demand both strength and complexity.

Heat Forging vs. Die Casting

Die casting injects molten metal into a mold under high pressure. It offers high efficiency but is prone to porosity and internal defects.

Heat forging reshapes solid metal, refining grain structure and producing a denser, defect-free material. Fatigue life exceeds die-cast aluminum by more than 3x.

The Heat-Forged Aluminum Unibody Process

The process integrates precise temperature control, mechanical design, and CNC finishing through six key stages:

1. Material Preparation

High-purity 7075 aluminum billets → composition testing → homogenization annealing to relieve stress.

2. Controlled Heating

Heated in an inert atmosphere to 420–480°C, with heating rate ≤5°C/min to prevent overheating or burning.

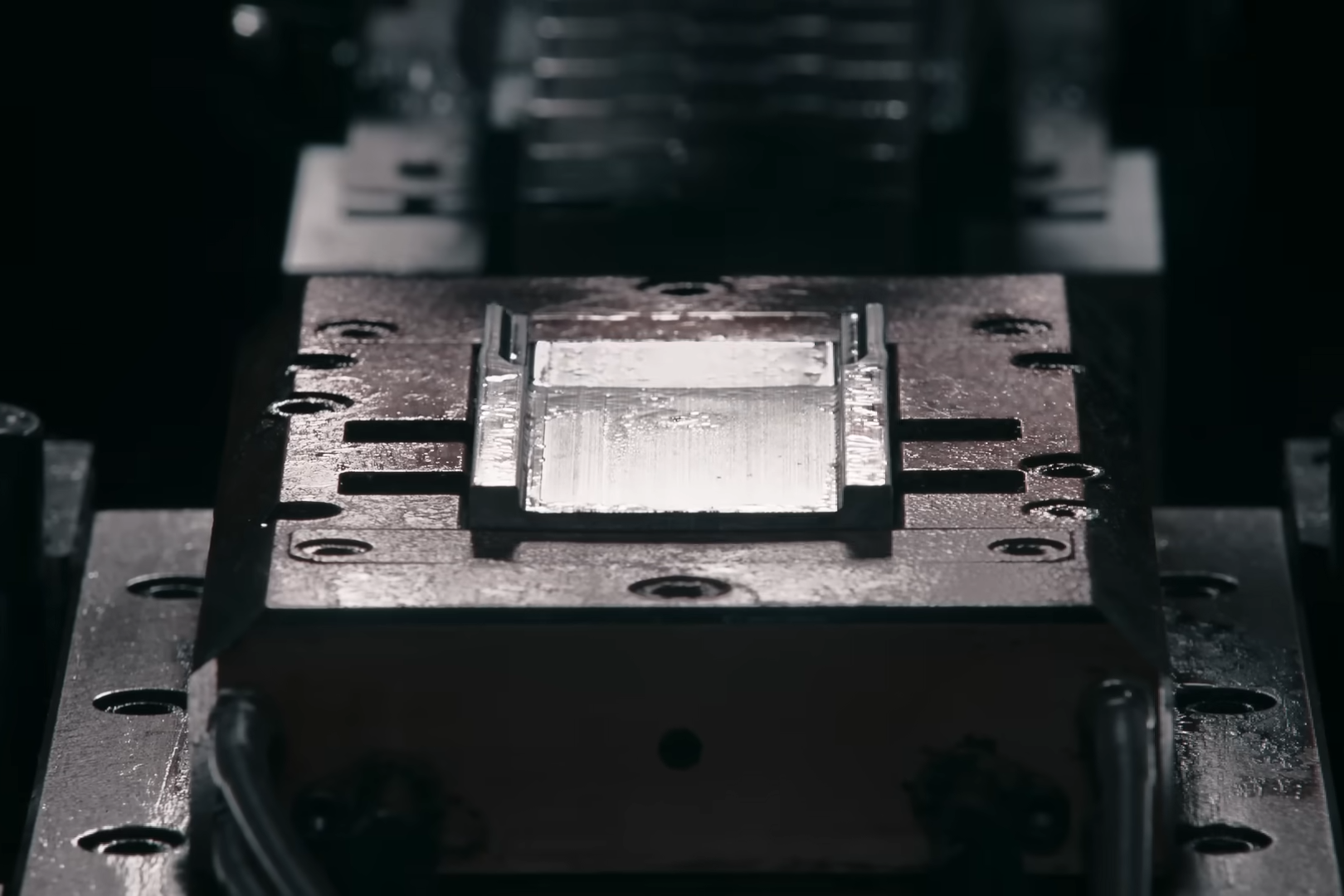

3. Die Forging

Transferred to a 5,000–15,000 kN forging press, forming the unibody frame—including the bezel and camera housing—in one stroke.

4. Heat Treatment

Solution treatment at 480°C → water quench

Artificial aging at 120–180°C → Strength increases by ~30%, ensuring drop resistance.

5. CNC Precision Machining

Five-axis CNC milling refines functional areas (ports, button slots, connectors). Tolerance controlled within ±0.02 mm.

6. Surface Treatment & Inspection

Anodizing or sandblasting for durability.

3D scanning + ultrasonic testing ensures 0.1 mm defect detection precision in critical areas.

Technical Advantages and Applications

1. Performance Gains

Grain refinement during forging improves overall mechanics. Compared to titanium housings, the iPhone 17 Pro’s aluminum frame achieves 20% higher bending strength while reducing weight by 15%.

2. Thermal Management

Aluminum’s thermal conductivity is about 20–30 times that of titanium. Combined with vapor chamber cooling, this allows the A19 Pro chip to sustain peak performance.

3. Design Freedom

Unibody construction removes assembly constraints, enabling large camera modules with 8x optical zoom while maintaining sleek aesthetics.

Beyond consumer electronics, heat-forged aluminum is also expanding into:

Electric Vehicles (EVs): Structural parts reduce body weight by 30%+

Aerospace: Forged 7075 alloy is widely used in landing gear and other load-bearing components.

Conclusion: Innovation Driving the Future of Manufacturing

The iPhone 17 Pro’s heat-forged aluminum unibody is more than just a design breakthrough—it represents a fundamental shift in modern manufacturing. By combining material science, precision forging, and advanced CNC machining, Apple has set a new benchmark for balancing strength, lightness, and design freedom.

From improved durability and heat dissipation to greater structural flexibility, this process highlights how innovative materials engineering can unlock both functional and aesthetic advancements. Beyond smartphones, the potential of heat-forged aluminum extends across aerospace, automotive, and next-generation consumer electronics, signaling a future where manufacturing innovation continues to push the boundaries of performance and design.