When you need a die-casting partner that handles every production stage with skill, Sino Die Casting is here for you. Since we first opened in Shenzhen, China in 2008, we have evolved into a smart, future-ready business that merges design, machining, and manufacturing into one smooth process. With our all-in-one service, you talk to just one team. That cuts out the headaches of juggling several suppliers and speeds your project straight from design to the finished part.

At the heart of our complete service is our unyielding commitment to high-precision mould making. Our experienced engineers and technicians know that the mould’s quality determines the accuracy and consistency of every die-cast part. That is why we invest in cutting-edge equipment, perform strict quality audits at every stage, and draw on years of practical know-how to create moulds that meet the toughest industry standards. Whether you need a simple mould for a single part or a complex multi-cavity design for high-volume production, we have the skill and equipment to deliver results that go beyond your expectations.

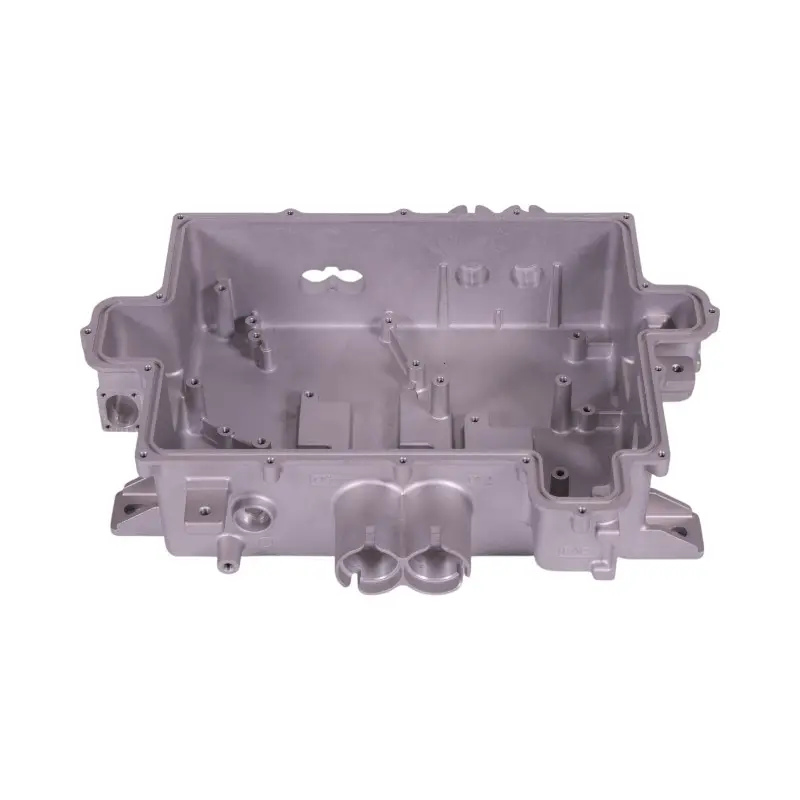

Die casting is where we shine. Walk through our bright, modern facility and you’ll see a complete lineup of machines primed to form aluminum, zinc, and magnesium alloys. Every step is rolled into one building: we source the alloys, craft the dies, cast, trim, and finish the surface. When you partner with us, we dig into your project—from part shape, strength demands, and surface finish—refining our method until the parts not only meet your specs, they exceed them. Keeping all steps in-house speeds up the schedule and builds your trust, because our experienced team oversees every aspect and guarantees total accountability.

We also offer CNC machining, essential for the exact tolerances and fine features today’s designs require. Our CNC workstations tackle everything from basic drilling and milling to advanced 5-axis machining, accommodating a wide range of sizes and shapes. By combining die casting and CNC machining under one roof, we slash lead times, simplify the workflow, and enhance quality control from the first pour to the final surface polish.

Once die casting is done, your part heads straight to CNC machining—no shipping, no delays. Your timeline stays intact. Custom part development is what we do best, so you deal with us, end to end. Many industries need features you won’t find on a shelf, and that’s where we excel. We create die-cast parts that match your exact blueprints.

From your first sketch, our team collaborates with you, guiding you on material choice, manufacturability, and design tweaks that cut costs while keeping quality high. The outcome is a part that meets your requirements and is affordable to make. Whether you want one prototype or 10,199 finished pieces, our full-service model takes you from idea to completion, with quality checks at every stage. This adaptable, single-source approach is why we keep getting repeat orders from so many industries.

We especially excel in automotive, where tight tolerances and long-lasting performance are must-haves. Our die-cast and custom parts are inside engine modules, transmission housings, structural frames, and suspension systems—delivering proven durability, mile after mile.

Our all-in-one solutions are powering the new energy sector from the ground up. We design and build parts for electric vehicle drivetrains, battery enclosures, and charging stations, keeping the entire energy network in perfect balance. In robotics, our precise components make sure each arm, sensor, and subsystem fires at exactly the right moment. The same careful engineering goes into telecom, where we supply the rugged parts network gear needs for ultra-fast, long-lasting performance. By housing design, mold-making, die casting, and machining all under one roof, we tailor every product to the unique needs of each sector.