Nov 24,2025

0

Za a iya amfani da fulawa mai tsauri wajen tafi-tafin sa hannu zuwa hannu na uku daga 250 zuwa 500 daraja Silisiyas koda yake ba ta haɗawa, wanda shi ne mai kyau daga cikin dalilin alama die casting ke koshi sai. H13 hot work steel yana farko akan hanyar haka, yana tsayin kari de sau biyu na canjin har zuwa lokuta na aluminum casting jobs. Nau'ikan sabon nan taron fulawa masu yawa sun hada da koro 5% chromium kuma kamar 1.5% molybdenum da aka kara guda ganin waɗannan rashin zuciya na har ya fara fuskantar aƙwai da aka yi, kamar yadda ya kamata a makon injiktaran pins ko kusan gates a kan mold.

Abun mutum na Chromium mai yawa da 4.5% yana ƙara kama'a ta hanyar dutsen ganyi yayin da ganyi mai nuchi ke faruwa da sahuwar madaidaici. Vanadium (0.8–1.2%) yana inganta tsarin rage, yayin da tungsten (1.5–2.1%) yana taimakawa wajen rage mai nauyi kuma silicon (0.8–1.2%) yana kara ma'adinan rage. Wannan abun takaingiya ta balanced tana kara halartu ne a cikin amfani da shi ta 23% dibu da alloys masu alaƙa a gyara zuwa zuwa a zinc die casting operations.

| Karfe daraja | Karo mai zurfi na zurfi | Matsalar (HRC) | Wani Range Mai Kyau |

|---|---|---|---|

| H13 | Mai kyau (1M+ cycles) | 48-52 | ≤800 bar |

| H11 | Mai kyau (500K cycles) | 46-50 | ≤600 bar |

| S7 | Mai zurfi (300K cycles) | 56-60 | ≤400 bar |

Karbon 0.40% na H13 yana ba da balance mai kyau tsakanin kama da gaskiya da aiki na wear, waɗannan suna sa ya zama mafi kyau don aluminium da magnesium die casting moulds da suke aiki sama da 600 bar.

Plasma nitriding yana ƙara girman surface hardness zuwa 500HV, kuma yana reducing erosion rates bi 40% a cikin core inserts da ke da exposure zuwa mai flow na metal. Grain refinement tare da vacuum arc remelting yana reduce inclusion size bi 90%, kuma yana significantly improving fracture toughness a cikin abubuwan muhimmi kamar slides da lifters.

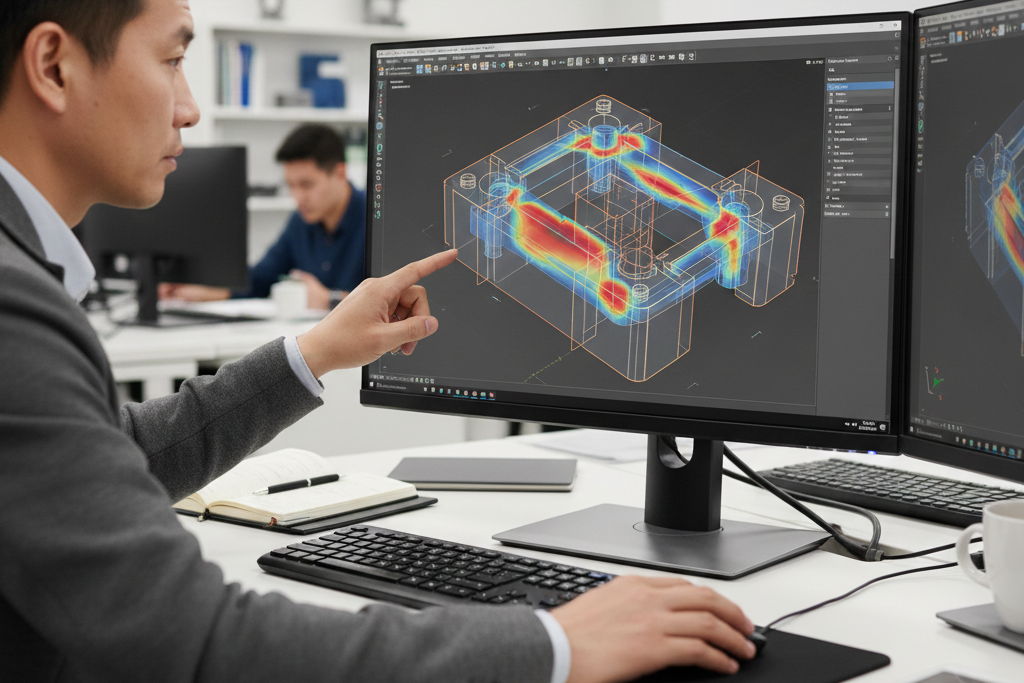

Idan ya kamata an koma zuwa kamar mahirin magana, yau da kullum zai kasance a sama sama bayan kowane dalilin wadansu. Yadda za ka iya canzawa shi shine tare da amfani da kayan aikin inginiyaru domin gano alamu na rashin aiki a farkon yanar gizon. Lokacin da aka gano, za a iya kara tsaro game da dukkanin abubuwan da suka fi karanci har ma za a fara amfani da kayan aikin, wanda zai sauke waqtin da kudin a karkashin.

Wannan da tsawon kewayon draft suka fihira daga baya uku daraja a kowaci gaba, suna cire sauran yanayin tsibiran da ke haifar da roughly 38% na wear na surface na mold saboda bayani na NADCA daga shekara ta gabata. Alamar da ke da tsananin radii mai zurfi ka fi halafa mita mili wanda aka nuna sune fara haifar da cracks sosai karancin alamar da ke da radii mai kyau. Sai dai kuma wailo ne a yi hanyar parting lines. Idan aka yi machining daidai cikin roughly 0.02 mm na alignment tolerance, zai kashe flash ya bada, abin da ke taimakawa wajen rage waɗansu abubuwan da ke furu lokacin da ya kamata.

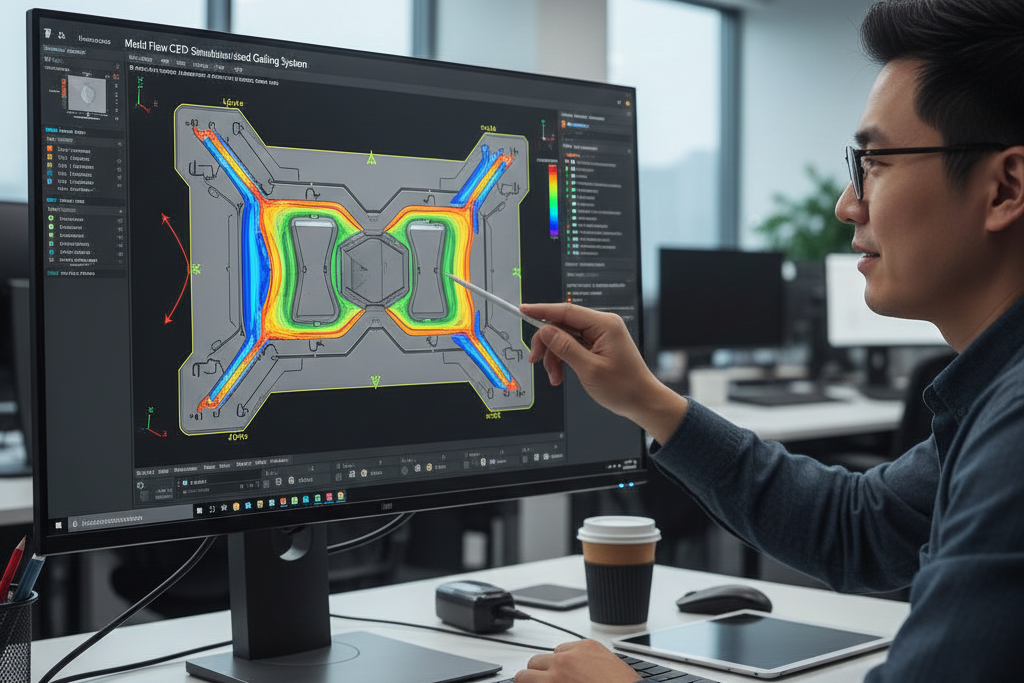

Gates masu girma da yawa karancin 12mm²/mm³ na casting volume suna haifar da flow mai zafi wanda ke burfi matakan steel 2.5x sosai karancin sauran hanyoyin da aka kirkirce. Nau'ikan runner masu angle 45–60° na entry suna kare impingement na direkta akan cavity walls yayin da fill speeds suna ze kuɗin 50m/s — wato hankali don durability na mould a cikin zinc da aluminum applications.

Gwajin DFM ta kansa 63% na alhakin tsoron fasaha ta hanyar yankin ma'auri da kayan dawo mai sauƙi. Ƙinunan mai iya canzawa sun kara yawan shekarar aiki na kayan ajiyar ta 200–300% karancin kayan ajiyar guda. Alhabar bayanai tsakanin abokan ƙirƙira da abokan ajiyar kasuwanci suna kare muhimman haɓakar harshen zafi da ma'auni, wanda ya sa hannun zafi ta fi dacewa.

Gudun harshen kyau ita ce wanda ke nuna yadda kayan ajiyar gudanarwa ke duruwa cikin ma'auni dangane da zafin zafi. Haɓaka mai zurfi ta kama da alhakin residual wanda zai gabatar da kagoro zuwa, na farko cikin kayan ajiyar da ke amfani da aluminum mai zafi a 600–700°C.

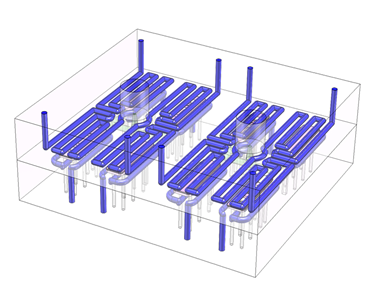

Tuyonin yankin daidaitawa suna biya tsarin abubuwan da ke nuna wadanda ke kullewa daban-daban, kuma ke kuskuren girman girma zuwa zuwa ≤15°C a karkashin dabam dabam. Wannan haɗin zai iya kullewa taimakawa wajen kullewa tushen daidaitawa, wanda ke kullewa 23% na kayan madai a cikin madai mai zurfi (HPDC). Gyarayan ruwa-da-glycol da ke runzo ne a 8–12 m/s suna kullewa hana 40% kyau karshen hanyoyin da ke yankiwa.

Idan a yi lafiya zuwa mai yawa na yanayi, abin da zai faru ita ce yadda zai canzawa girman wani abubuwa a lokacin waɗannan alamar baya. Wannan tsarin ya kare tafaddun yanayin yanayi sosai, har maƙa karshen 34% a karkashin tsarin yanayi mai tsada. Abin da wasu masu amfani suna amfani da su ne shine alamar yanayin yanayi kamar nitridin aluminum chromium ko AlCrN kamar ma'ana. Wadannan alamar suna aiki ta hanyar kara ingancin lokaci da ke tafiyan cikin kayan ajiyar ganyi. Ga abi ƙasa na Tooling International daga shekara da suka gabata, wannan yana taimakawa wajen kara tafadunci da kuma ingancin angyaci game da karshen 19%. Yau da kullum aikin biyu waɗannan suna iya hada da ma'ana sosai. Masu amfani suna nuna cewa kayan H13 su ke samun karshen duka 2,000 zuwa 3,000 alamar amfanin halitta kafin za su buƙatar ayyukan gyara ko kara ayyuka. Wannan yana da kyau sosai saboda yake da kyau sosai yadda yake da kyau sosai.

Tsarin dauke mai yawan yanki ya hada canjin girma na coolant ±2°C ta amfani da bayani na sensor na infrared a lokacin dogon, ke ba da damar samun tsibiran kusa sai dai ma a watar zama da watsi. Wannan tsayin 10 seconds ko karanci akan 45 seconds ya kuma nema abubuwan da ke tsakanin 8%, amma tsarin dauke mai canje-canje yana koyo girman tsakiya ≤300°C, yayin da ke koyo alhassar. Wannan hanyar yin aiki tana koyo inganci na 85–92% yayin da tana tabbatar da irin ayyukan produce na annabisa.

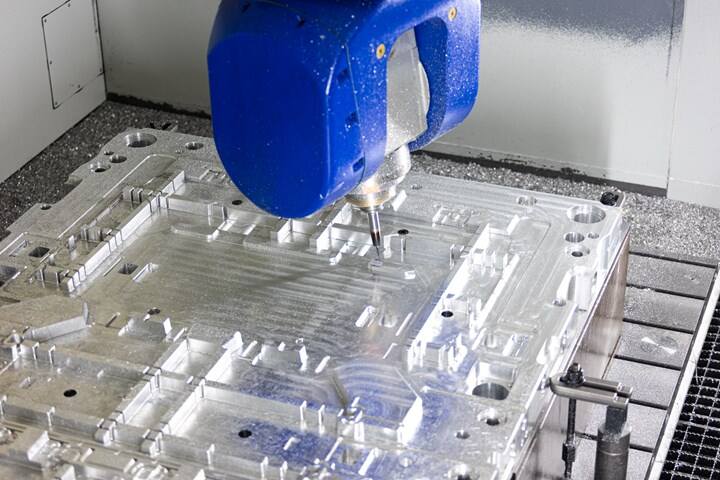

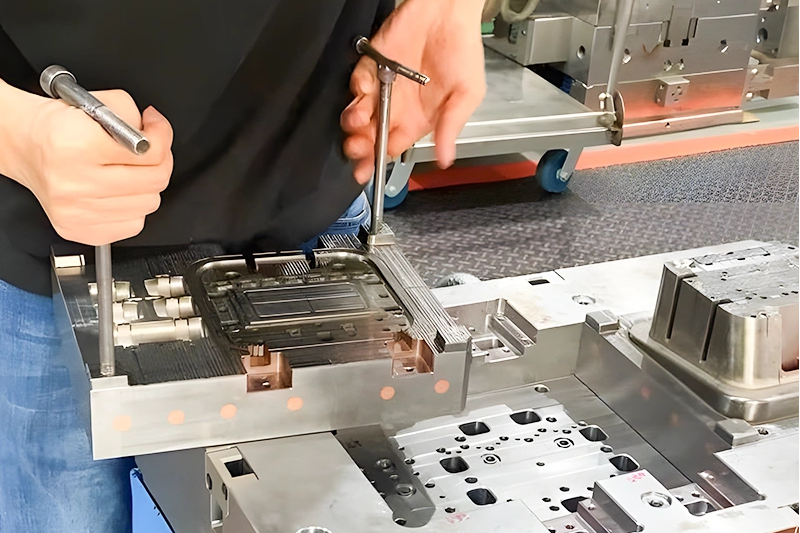

An gurbin da ke tsakanin suna kirkirar dukaɗin abubuwan da ke j внутри na farko, sai an tsarin zuzuma yana iya mahimmanci wajen fitar da waɗannan abubuwa masu tafiye taushe ba su kuskuren. Wannan yanayin shigarwa, muna yi imama zuwa ga alikali mai kyau masu uku da likita 45 ko fiye ne a cefin Rockwell C. Waɗannan kayan aiki suna samun shekara sosai kamar yadda suka kasance, kamar yadda suka shiga cikin yankin uku da sa biyu. Kuskuren daya kasa da 0.025 millimeters ne kama da + ko - zai iya hada karfi na kuskure a kansu ta hanyar kama da 18% saboda labarin da aka fada a Journal of Materials Processing a shekarar 2023. Don haka mun godiya ga iyaka, neman iyaka da takwashe da aka yi ita ce ya bambanta. Sai dai kuma za mu yi la'akari da waɗannan meshin CNC na iya yin galibi mai zurfi da ma'anar da ke sama da Ra 0.4 micrometers, wanda ya kama da raba ayyukan kimiyya na baya ta hanyar kama da uku sharu.

Daidai CNC suna iya samun tsarin anguleri a karkashin wataƙila ko fiye da 0.001 daraji, wanda ke mahimmanci lokacin da kuka yi kanalin tushen tushen yanki da kuma kula da abubuwan da ba su yanke saboda haliyar ruwa. Anan gargadi suna aiki kyau lokacin da aka haɗa su da bushings da ke da flatness na 2 microns ko fiye, wannan haɗin halayen ya daina abubuwan logamai su kula a lokacin aiwatarwa. A cikin alamuwar alamuwa, gyara na real time sun kama da karamar kuskuren ayyukan matakan gaba biyu a karkashin hanyoyin na yau da kullun. Muna ganin wannan abin da ya faru a wasu gwaji mai zuwa tare da karbar kasuwa ta otomatik a 2024 bisa waƙatin kiyaye ayyukan sarrafa sarrafawa.

Takaitaccen dabbobin daga Metalworking a shekarar 2023 suna nuna cewa kungiyar ayyukan gyara-gyaran yau da kullum ta kare juzu'in batun gaban kuskuren da ba a tsamman karfi ba ne sai dai 35% dibuwa kan zama za a yi karfin bayan wani abu ya puru. Lokacin da masu amfani da kayayyaki ke dubawa kayayyakansu waƙe-waƙe, suna ganin alaramtai na farko kamar yadda gates ke fara kurkuru ko kari-karin mai zurka ke kirkirar. Wadannan matsaloli masu karkashin yawan millimeter 0.5 zuwa shekara amma za su sami su kafin su kirkiri matsala mai mahimmanci a lokacin amfani. Kayayyaki mai zaman kanso kamar cavity pressure sensors da fasaha thermal imaging su taimaka wajen samun wannan matsala kafin 5,000 operating cycles. Gyara wadannan matsalolin maƙurna yana kwaro sakamako mafi ƙarancin uku ne ga ma biyo a matsayin mayar da kayayyakin komawa, yayin da wani kungiyar ayyuka ke koyaushe shi ne mai mahimmanci don sadarwa da kuma ikojiyar sadarwa ga yankin masu amfani.

Wani tsarin gudun matakan 6 yana kara ingancin cin zarar ta hanyar 40–60% a cikin aikojin mai ƙwayoyin zarra:

Mafarkin da ke biyuwa wannan tsarin samawa suna samun karshen yawan 200,000 sauƙi akan yankin matakai bayan kammalitin sabada, sannan su barin taimakon girman ±0.1%

Mamaki ne kyaukaka na gudu ke mahimmanci saboda die casting yana iya canzawa da hankali. Abubuwan da ke tafi da wannan canje-canji ya kare ruwututtuka kuma ya fara gabatar da rayuwar keke.

Composition na alloy zai iya inganta gyara zuwa ga oxidation, stabilitin tempering, alkarhuwar gudu, da hot hardness, wanda dukka ke fara gabatar da rayuwar keke da performance.

Angles na draft masu lafiya suna kara teburin ejection da wear na surface, yayin da corners da aka radius su kare ruwututtuka, wanda ke fara inganta durablity na keke duk

Tasawen da ke yanke karfin yake suna iya samar da zane-zane na tsawon shafin cikin alamar, sanya alaƙa mai zuwa, kuma takaingi matakan karfi ko masu kurumtsu.

Makonan da ke dauka lokaci, kayan amfani na farko don warware, sauyin sauƙi, da tabbatar da ingancin daidaitowa suna dadi ayyuka da suka ƙara yawan shekaru na alamar kuma sanya kashewa.