Nov 24,2025

0

Steel ụlọ nche nwere ike ime ka eji oyi ya na-agbasa n'etiti 250 ruo 500 degrees Celsius ma ọ bụghị ịdị njọ, nke bụ otu n'ime ihe kachasị mkpa maka ihe ndi dị mgbagwoju anya ekpuru siri ike. Steel H13 hot work dị mgbagwoju anya, na-adọrọ adọrọ ebe ọ bụla mgbe eji ya na-alaghachi oyi milionụ mgbe e ji ya na-acha aluminim. N'obi abụọ gbasara ahu, ụlọ steel ahụ nwere ike ibute chromium site na 5 percent ma ọ bụ molybdenum site na 1.5 percent iji cheba ya na-emekarị oyi n'ime ngwaọrụ ndị dị n'akụkụ ejector pins ma ọ bụ akụkụ gates n'ime mold.

Ihe nwere Chromium dị ukwuu karịa 4.5% na-eme mmetụta maka ikpuchi ike ime mkpa mgbe eji ya mee obosara n'akụkụ ahụ dị ka mmiri ahụ iri. Vanadium (0.8–1.2%) na-enyere aka ime mkpa gịnịgịnị, mgbe ebe tungsten (1.5–2.1%) na-enye oke ọkụ ma si (0.8–1.2%) na-enyere aka ime mkpa gịnịgịnị. Ntụpọ a dị omimi na-enyere oge ọrụ karịa otu afọ iri abụọ na atọ pụrụ iche n'ime nzukọ nkata na-enweghị akwụkwọ bọtani n'ime nzukọ nkata zinc.

| Ọkwa Steel | Nchekwa thermal fatigue | Mmetụ (HRC) | Ọgu Oke Oke Dabere |

|---|---|---|---|

| H13 | Omere mma (1M+ cycles) | 48-52 | ≤800 bar |

| H11 | Omere (500K cycles) | 46-50 | ≤600 bar |

| S7 | Nke dị ọcha (300K cycles) | 56-60 | ≤400 bar |

Ihe nwere karbon 0.40% nke H13 na-enye usoro kacha mma maka ikikere ike na onwe ya ma ọ bụrụ na eji ya eme ihe na-alaghachi aluminom na magnesium die casting moulds nke na-aga karịa 600 bar.

Igbanwe pasma na-enyere aka ịdị elu nke 500HV, na-emejọta ohere ikiri site na 40% na core inserts nke na-ahụ maka mmiri nke metal. Iji vacuum arc remelting wee tinye gransị na-adaba ohere nke akpụkpọ site na 90%, na-enyere aka zuru oke maka ikiri ike na ndị bekee dị ka slides na lifters.

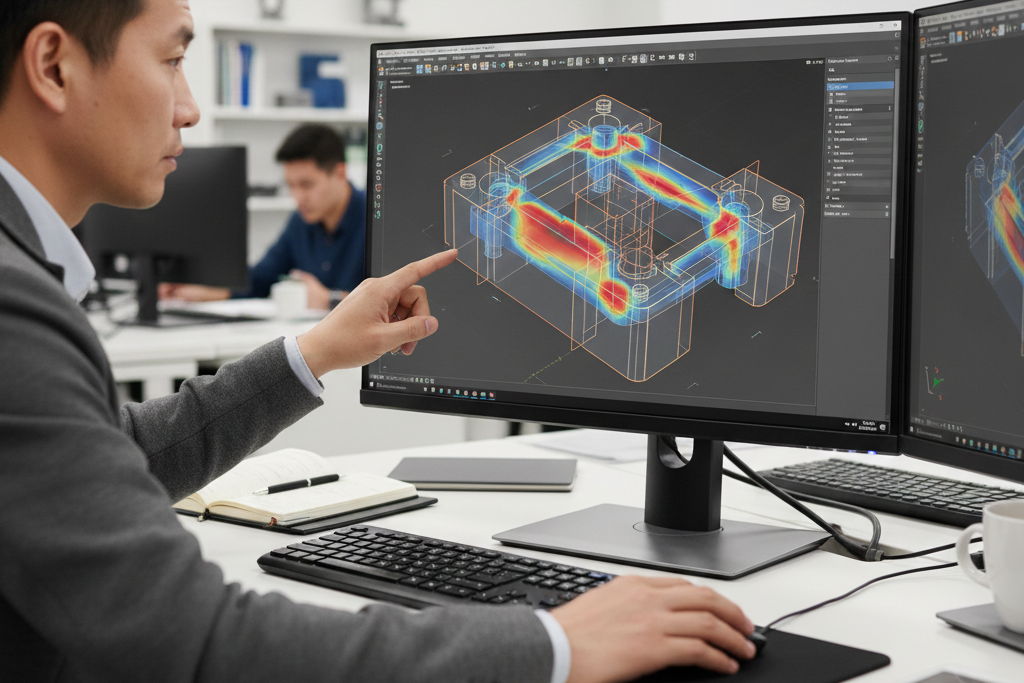

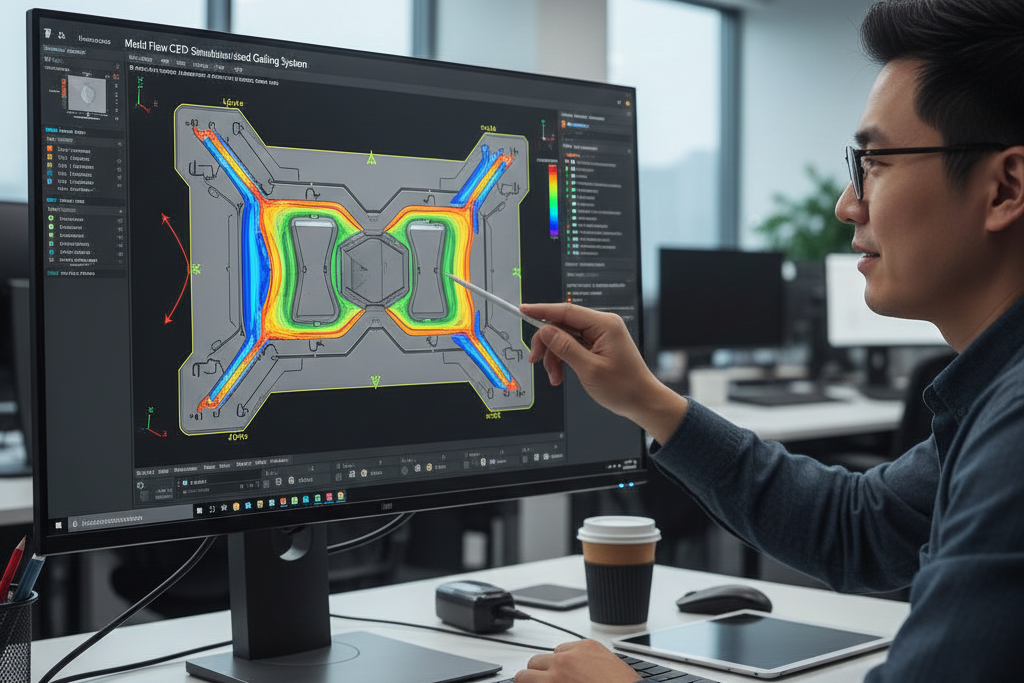

Mgbe ị na-ahụ maka nkwasi ihe nguya, ike ikpuchi ike dị ka opekọrịta n'akụkụ mbụ nke akwụkwọ nke onwe onye. Iji nyocha nyocha nyocha nwere ike inyere aka n'ụzọ dị iche iche. Dịka ọmụma, ime mgbanwe zuru oke mgbe ọnụ ụzọ dị obere na eme ka ọnụ ụzọ dị ala 3mm maka ngwaahịa alaminiom dị ka enweghị ike inwe ike nke abụọ ma ọ bụ atọ na mpaghara ndị dị njọ dị ka mpaghara core pin na mpaghara agba-agba. Ugbu a, otu ndị onye ọrụ ọrụ karịrị na-enye mmasị maka nhazi software maka ịhazi mpaghara njọ mgbe ebe nyocha nyocha. Mgbe ahụzoro, ha nwere ike imepụta ya site n'ime ihe ndozi tupu ọ bụla na-adịghị mma, nye aka ịgba na ego n'ụbọchị ndị na-esote.

Ọ bụrụ na akụkụ draft zuru ebe ọ dị elu karịa 3 degrees na akụkụ, ha mere ka oke ejection dị n'akụkụ 38% nke njide mold niile gafee data NADCA site na afọ gara aga. Ngwaọrụ ndị e mere na akụkụ dị nta karịa mm na anọchite anya 0.5 mm enweghị ike imebelekarịrị mgbe ọ dị mfe karịa ngwaọrụ ndị e mere na akụkụ dị mma. Ikwesiri ịmata ma ọ dị mma otú ahụghị parting lines. Ọ bụrụ na e mechined maka ọ dị mma n'ime 0.02 mm alignment tolerance, ọ kwalite ya na-eme flash, ihe kpatara ka ngwaọrụ ghara ịdịrịsịrị mgbe ọ dịrị.

Gates ndị ukwuu karịa 12mm²/mm³ nke ume casting mere mkpọtụka ndị na-erode akụkụ stell 2.5x mfe karịa usoro ndị nzukwu. Usoro runner ndị na-adị n'ọnụ 45–60° mee ka ọ dị ntakịrị na akụkụ cavity mgbe ọ na-ejide oke fill n'okpuru 50m/s — ihe kachasị mma maka ndụ sustainable mould na zinc na aluminum applications.

Ise DFM wezu 63% nke mkpụrụ ndị dị n'ime ihe ngosi n'ihi mmụta akara atụmatụ na njikọ ejection gbakwụsịrị. Nche modulu nwere nkata gbasara enyere oge ndụ nke ngosi site na 200–300% karịa nke monolithic. Nkwalite nlegharị anya n'etiti onye chepụta akara na onye nnukwu foundry mere ka coefficients ntụpọ thermal si dị na parameters cycle dịdị, wee wezu ihe ngosi thermal.

Ịkwandu thermal zuru ezu bụ ihe kpatara ka die casting mould ghọbi ma ọ bụrụla ọ na-agba ụgwọ n'ime usoro thermal mgbe ọ na-achọpụta akara ya zuru ezu. Ịgbakọ heat zuru ezu wezu stresses residual ndị na-eme abani mgbe ochie, site na moulds ndị na-ahụ maka aluminum mpụmpụ n'ime 600–700°C.

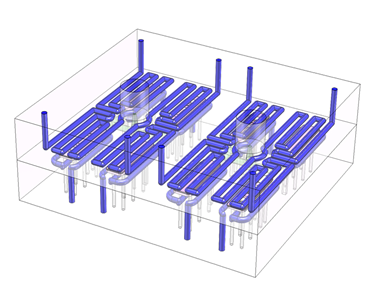

Ebe akwara ụtọ na-ezutu ike nchịkọta ikpo maka ịgbatị ikpo ụtọ, na-achọpụta mkpa ụtọ ruo ≤15°C n'akụkụ ebe dị mkpa. Nke a na-enyere aka ịdịghị ekpuru ikpo, nke bụ ihe onwunwe 23% n'ime ngwaọrụ die casting (HPDC) dị elu. Mmiri-glycol mixtures flowing at 8–12 m/s na-ekwu ụtọ iri mgbara 40% karịa usoro straight-bore nke ochie.

N'akụkụ njikọ nke mmiri na-acha, ihe dị ka ịdị ndị a bụ na ọnụ ọgụgụ mmiri na-agbanwe mgbe e wezụga ya. Usoro a na-ewepụ mkpụmkpụ anụnụ aka n'ụzọ dị ukwuu, nke pụtara otu iri na anọ na narị iri anọ (34%) n'agbanyeghị usoro mmiri akpapụrụ. Ihe ọzọ onye ọrụ na-amalite ime bụ ngwaọrụ nkụnye nkụnye oji dị ka aluminum chromium nitride ma ọ bụ AlCrN n'akụkụ. Ngwaọrụ a na-arụsi ike site n'ikpuchi oge ike nke ụgbọ mmiri na mpaghara mold. Gbasara Tooling International gara aga afọ, nke a na-enyere aka ịghapụ ụfọdụ ike ikpokọta na ikpokọta n'otu iri na ise (19%) n'otu iri. Iji usoro abụọ ha na-ejikọta otu, enweghị ike ime mmetụta dị ukwuu. Onye ọrụ mold na-ekwu na mold H13 steel ha nwere ike ịdụ mbụ n'etiti iri abụọ na iri atọ (2000 ruo 3000) mgbe ọ bụla tupu ha chọrọ ọdịnala ma ọ bụ nhazi. Otu ihe dị mma n'ihi na ọ dị njikere n'obi ụtọ.

Ịsọpụrụ nkeji na-akpaghị aka iji nyefee ọnụ ọgụgụ mmiri n'ime ±2°C site n'iji ndabere nkeji n'abalị dị ka akara irinfrared, nye ya ike ime mkpụrụ nzuko soro maka ọdịdị thermal. Iji oge kacha obere karịa 45 sekọnd na-agbanwe ụbọchị nke mould site na 8%, mana ịsọpụrụ dị otú a na-achọpụta ọnụ ọgụgụ aka n'okpuru ≤300°C, na-enye mmetụta. Usoro a na-achọpụta 85–92% uptime mgbe e na-ahụ nkwarụ njemụaka afọ.

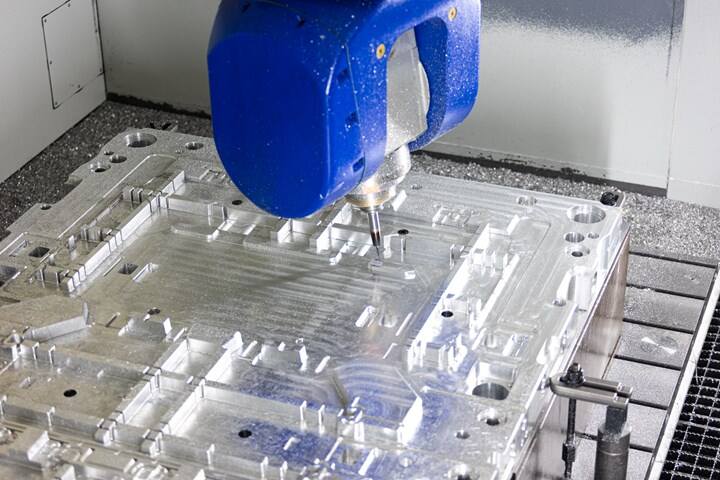

Ndị aga nke dị na akụkụ ahụhụ eji mepụta akụkụ ike na-egbu egbu ahụ, ma ọ bụrụ na sistemụ ejector na-enye ohere dị mkpa maka ịwụnye ndị aghara anaghị ekwe omume. Mgbe ị na-ekwu okirikiri, anyị na-ekwu maka steeli ala dị ịrịba ama eji arịwanye ozi olekarịa Rockwell C puku 45 ma ọ bụ karịa. Ndị a na-achọpụta akụkụ ha n'ezie ebe ọ bụla mgbe ha na-agbasa laba otu narị puku afọlabụnari ikpeazụ. Njedebe nke obere n'akụkụ abụọ aka 0.025 milimita puku ma ọ bụ minus pụtara ka enwere nnukwu njedebe n'akụkụ usoro ịgbagharị site na 18% gbasara akụkụ akụkụ Journal of Materials Processing tupu afọ 2023. Ya mere, ihe atụmatụ dị mkpa n'okwu a, ime ihe atụmatụ dị ala karịa iri mikromita bụ ihe dị mkpa. Ma ọ bụrụ na anyị amaghị ya, ọ dịghị ike ịkpata akụkụ CNC dị elu. Ha na-eme akụkụ dị ụtọ nke karịa Ra 0.4 mikromita, nke na-ewepụ akụkụ ike ọzọ dị mkpa maka inweta akụkụ site na otu narị afọlabụnari ikpeazụ.

Igwe CNC ise akụkụ nwere ike ịgbakọta ngwaọrụ n'akuku na-adịghị elu ma ọ bụ na-abịa n'akụkụ 0.001, nke pụtara nnukwu ihe mgba mgbe ị na-arụ ọrụ na mbido mmiri na-enyere aka ma weghachite ịdị ọsọ site na agụ. Ndị okenye ndị na-enyere aka karịa mgbe eji ha wepụta bushings ndị na-ekpuchi obere ọnụ 2 microns, usoro a ghaghachigara ịdị n'akụkụ nke ngwaọrụ metalikụ mgbe ọ na-agbanwe. Mgbe ị na-agbasa ozi maka ngwaọrụ, nhazi oge ochie enweghachi ohere nke atọ abụọ karịa usoro zuru oke. Anyị mara ya n'oge ụfọdụ na testụ gara aga na dies nke ugboama n'afọ 2024 dịka e kọwara na ulo ọrụ ngwaọrụ edemede ndị ugbua.

Ndịbịa nke na-eme n'ime ọmụmụ ahụhụ na afọ 2023 ekpughe ebe onye ọrụ mechaa mkpebi emebi maka ịgbadị mgbe ọ dịghị ike ime ihe karịa mgbe ọ bụrụ na ihe mere eme. Mgbe ndị ọrụ mechaa ngwaọrụ ha n'ụbọchị, ha na-ahụ nkọwa mbụ dị ka mgbe akpụkpọ anaghị aga ma ọ bụ mgbe egbu egbu dị n'ime ihe. Nkọwa a na-arị n'otu millimeter na mbụ karịa otu afọ mana achọtara ha mgbe ha abụghị ike ime nsogbu ukwuu n'ime ọrụ. Ngwaọrụ ọfụna dị ka sensorụ mkpuchi mmiri na ngwaọrụ nhazi oyi na-enyere aka ịhụ nkọwa a mgbe niile na-enwe otu iri na ise ngwa ngwa. Imekọ ihe a dị ntakịrị na-enweghị otu atọ nke ịdị njikọ ihe ọkụkụ, nke mere maka ụlọ ọrụ ụfọdụ mechaa nke a bụ ihe pụrụ iche maka ego na ọrụ.

Ọnụọahịa 6 dị ka mkpali nke mkpali nke nzube ndụ mmiri site na 40–60% n'ime ihe ngalaba dị otú ahụ:

Ndị ọrụ ugboro gbasara usoro a kpọchiee ọnweghị ike karịa 200,000 mgbe e nyere ya njehie n'akụkụ na-achọpụta obere ihe dị ka ±0.1%

Mkpa nchekwa nke ọtụ ọtụ dị mkpa sị ohere die casting pụtara ịgbasapụ ọtụ ọtụ n'ụzọ zuru oke. Ngosi ozi ndị ga-enwe mkpa n'ime ọtụ ọtụ enyere aka ịmachi ụzọ na-enyere aka ịdị ndụ oge ole na-ejide mould.

Isi ngosi ozi nwere ike ime mkpa nke oxidation, mmalite nke ọtụ ọtụ, ịdị iri na-aga n'ihu na mma ọtụ ọtụ, ndị a niile nwere ike ịdị ndụ oge ole na mma nke mould.

Ike egwu akpụkpọ na-eme ka ike ejection wee gbagwo ji, ma ọ bụrụ na akụkụ ndị dịrị mgbe dị egwu enyere aka imechara nchekwa nke moulds.

Sistemu cooling dị mma si mee ka oyi dị otú ahụ n'ime mould, na-eme ka ike residual dịnụ ma weghachite ya na crack ma ọ bụ njedebe dị elu.

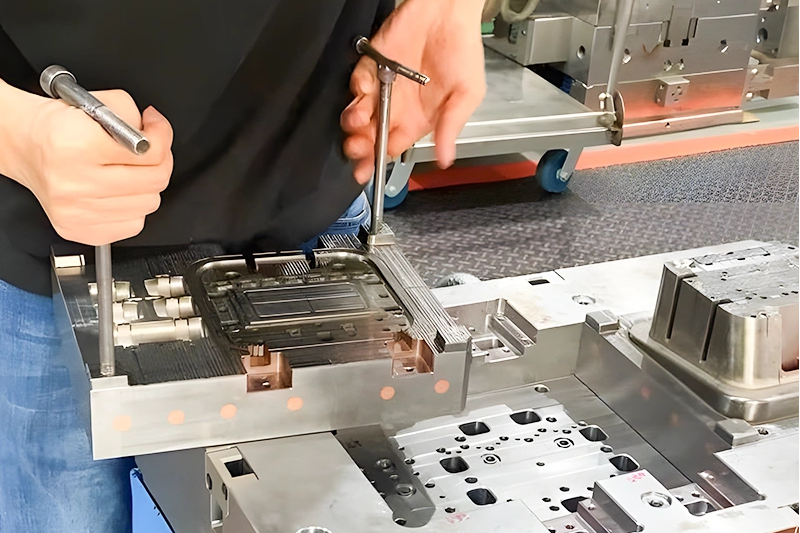

Nlele nke ọma, usoro nhazi, inwe ike ịmụtakwu, na ntinye akara nke dị mma bụ ihe mere eme ndị dị mkpa nke na-enyere aka imekarị akụkụ mould ma weghachite ya na-adaghị agbasa.