The Importance of Aluminum Die Casting in Electronics Manufacturing

Why aluminum die casting is critical for electronics industry applications

Aluminum die casting has become indispensable in electronics manufacturing due to its unique combination of thermal conductivity, lightweight properties, and structural integrity. Over 84% of electronics manufacturers now use aluminum die-cast components for critical applications like heat sinks, device enclosures, and connectors.

Key advantages include:

- Superior thermal management: Aluminum alloys dissipate heat 2.3x faster than plastic alternatives.

- EMI/RFI shielding: Die-cast housings provide inherent electromagnetic interference protection.

- Durability-to-weight ratio: Aluminum components withstand daily wear while reducing device mass by 30-40% compared to steel.

The process enables complex geometries with wall thicknesses under 0.8mm – critical for modern smartphone and laptop designs while reducing assembly steps by 60% compared to traditional fabrication methods.

Growth trends in die casting for the electronics sector

The global market for aluminum die-cast electronics components is projected to grow at 7.2% CAGR through 2029, driven by:

- 5G infrastructure expansion: Requires lightweight, heat-resistant base station components

- IoT device proliferation: Demands mass-production of standardized housings

- Circular manufacturing initiatives: 95% recyclability of aluminum alloys supports sustainability targets

Advancements in high-pressure die casting (HPDC) achieve surface finishes under 1.6μm Ra, eliminating post-machining for visible consumer product parts while maintaining tolerances within ±0.15mm.

Achieving Tight Tolerances (±0.1mm) Using HPDC for Electronic Components

HPDC achieves dimensional tolerances as tight as ±0.1mm by injecting molten aluminum into steel molds under extreme pressures (10,000–20,000 psi). This precision eliminates the need for secondary machining in 78% of cases.

| Casting Method | Typical Tolerance | Surface Finish (Ra) |

|---|---|---|

| High-Pressure (HPDC) | ±0.1mm | 1–2.5 μm |

| Sand Casting | ±1.0mm | 12–25 μm |

| Permanent Mold | ±0.4mm | 2.5–7.5 μm |

Role of Precision Engineering in Complex Aluminum Die-Cast Parts

Modern HPDC relies on three engineering advancements:

- AI-Powered Flow Simulation: Predicts microdefects in components with sub-1mm walls

- Modular Mold Systems: Allow multi-configuration parts without full die replacement

- Closed-Loop Process Control: Adjusts parameters using 200+ sensor data points per cycle

These innovations reduce post-casting quality issues by 40% compared to traditional methods.

Case Study: HPDC in Smartphone Frame Production

A leading manufacturer transitioned to HPDC for 7000-series aluminum frames, achieving:

- 55% faster production cycles (23 seconds per frame)

- 30% reduction in material waste

- Consistent 0.12mm antenna line gaps across 2 million units

Key Applications in Consumer Electronics and Wearables

Aluminum Die-Cast Casings and Frames for Smartphones, Laptops, and Tablets

Aluminum die casting enables ultra-thin yet durable frames with wall thicknesses as low as 0.6mm. Manufacturers leverage aluminum's EMI shielding properties to protect 5G/6G antennas while reducing device weight by 12-18% compared to steel.

Use of Die Casting in Smartwatches and Fitness Trackers

HPDC produces seamless unibody smartwatch cases with integrated sensor mounts, achieving IP68 waterproof ratings through precise 0.05mm gap tolerances.

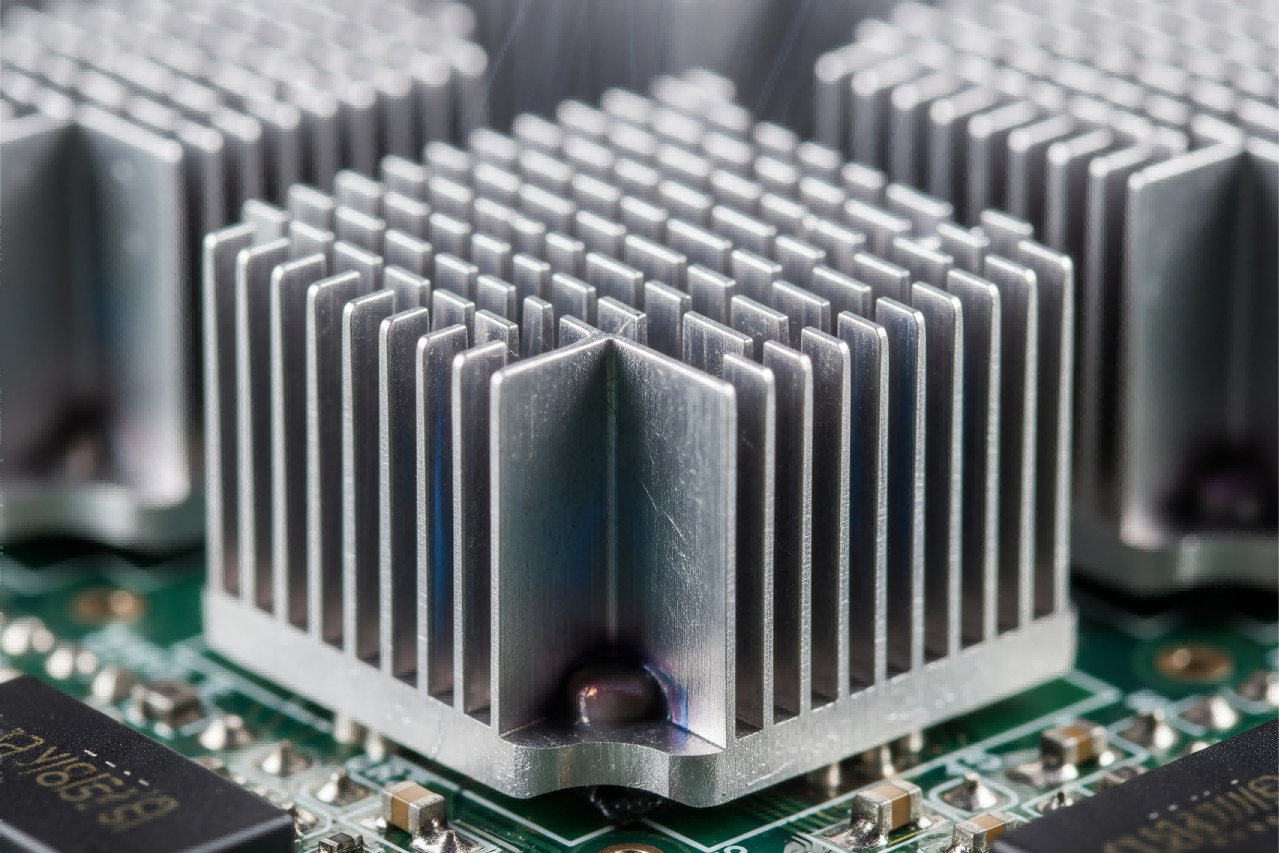

Thermal Management Advantages of Aluminum Enclosures

Aluminum's 205 W/m·K thermal conductivity solves heat dissipation challenges. Die-cast enclosures with integrated heat sinks reduce CPU temperatures by 8-12°C in gaming laptops compared to plastic housings.

Innovations in Aluminum Alloys and Lightweight Design

Advanced aluminum alloys (AlSi, Al-Zn, Al-Mg) for electronics

| Alloy Family | Key Properties | Applications |

|---|---|---|

| AlSi | High fluidity, thermal conductivity | 5G housings, heat sinks |

| Al-Zn | Superior strength-to-weight ratio | Foldable phone hinges |

| Al-Mg | Corrosion resistance, EMI shielding | Smartwatch cases |

These alloys enable 0.6mm wall thicknesses while maintaining 150-200 MPa tensile strength.

Corrosion-resistant alloys for durable, long-lasting devices

New Al-Mg-Cr formulations demonstrate <0.05% mass loss after 1,000 salt spray hours, outperforming painted steel by 4X.

Lightweighting benefits for portability and energy efficiency

Aluminum's density (2.7 g/cm³) enables 35-50% weight savings versus steel, with cascading benefits:

- 18% longer smartphone battery life

- $0.38/unit lower tablet shipping costs

- 92% user comfort scores for wearables

Sustainable Production and Cost Efficiency in Aluminum Die Casting

Eco-Friendly Aspects of Aluminum Recycling in Die Casting

90% of cast aluminum contains recycled content, reducing energy consumption by 95% versus primary production.

Cost-Effective Manufacturing Through Rapid Prototyping and Tooling Innovation

HPDC enables cost optimization through:

- Tooling durability to 500,000+ cycles (63% cost reduction)

- Digital twin integration cutting prototyping iterations by 75%

- 98.6% material utilization rates (40% lower than CNC machining)

Production cycles reach 150 components/hour for smartphone enclosures while maintaining ±0.25mm consistency.

FAQ Section

What is aluminum die casting?

Aluminum die casting is a manufacturing process that involves injecting molten aluminum into steel molds under high pressure to create complex geometries and precise components.

Why is aluminum used in electronics manufacturing?

Aluminum is used because of its excellent thermal conductivity, lightweight properties, electromagnetic interference shielding, and structural integrity, making it ideal for components like heat sinks and device frames.

What are the advantages of high-pressure die casting (HPDC)?

HPDC offers tight tolerances, eliminates post-machining in most cases, and produces components with superior surface finishes, making it cost-efficient and precise.

How does aluminum die casting support sustainability?

A large percentage of aluminum used in die casting is recycled, significantly reducing energy consumption and supporting circular manufacturing initiatives.

Table of Contents

- The Importance of Aluminum Die Casting in Electronics Manufacturing

- Achieving Tight Tolerances (±0.1mm) Using HPDC for Electronic Components

- Role of Precision Engineering in Complex Aluminum Die-Cast Parts

- Case Study: HPDC in Smartphone Frame Production

- Key Applications in Consumer Electronics and Wearables

- Innovations in Aluminum Alloys and Lightweight Design

- Sustainable Production and Cost Efficiency in Aluminum Die Casting

- FAQ Section