How Surface Finishes Enhance Die Cast Part Performance and Longevity

Improving corrosion resistance in die cast parts through surface treatments

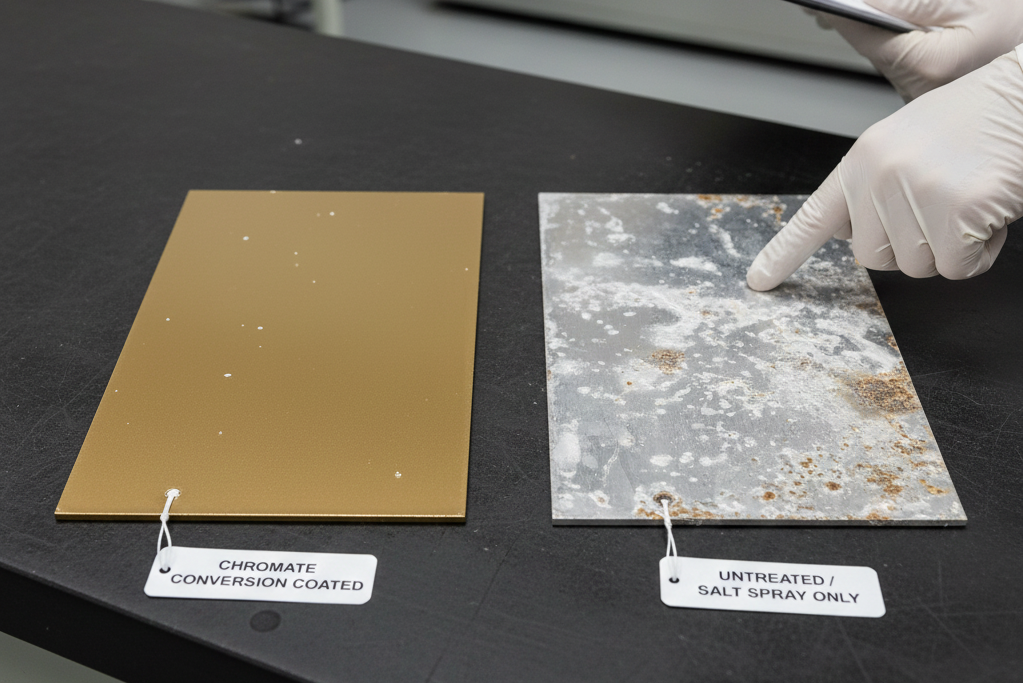

Coatings like chemical conversion treatments and anodizing create protective layers that help keep aluminum and zinc alloys safe from moisture damage, salt spray, and harmful chemicals. A recent study from NACE International found that aluminum components treated with chromate conversion coatings lasted well over 500 hours in salt spray testing, which is about 70% longer compared to parts without any treatment at all. The science behind these treatments involves creating thin oxide layers at the molecular level or applying substances that stop corrosion from happening. This makes them really useful for preventing issues like pitting and galvanic corrosion problems in places where metal gets exposed to harsh conditions, whether it's boats in the ocean, cars on roads, or equipment used in factories.

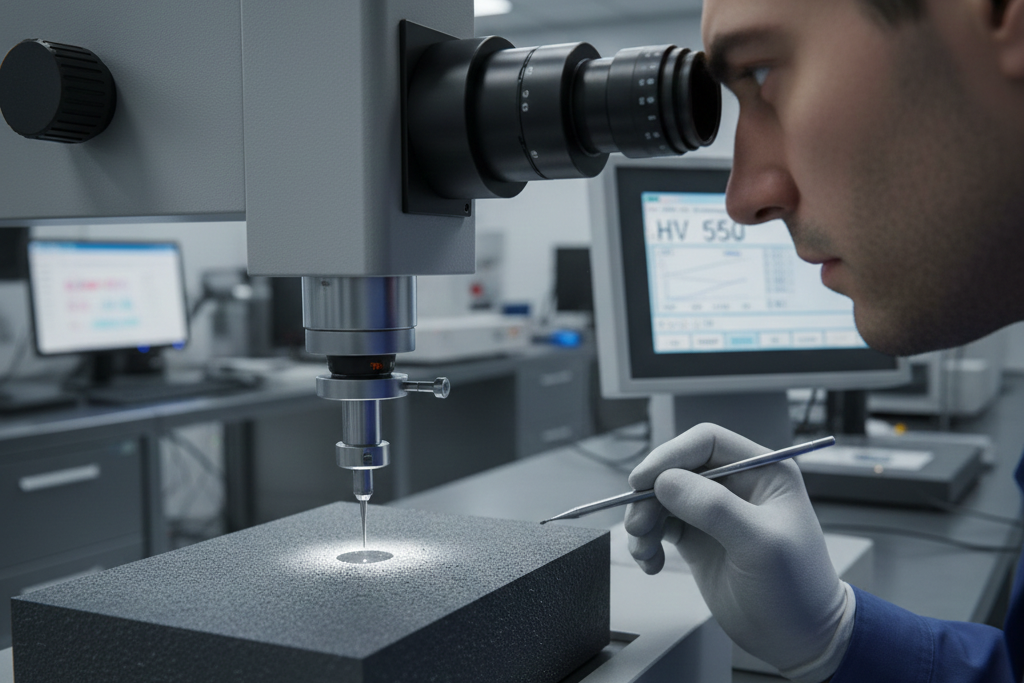

Enhancing wear resistance and mechanical durability with functional finishes

Surface treatments such as hard coat anodizing and thermal sprayed ceramic coatings boost surface hardness to around 1500-2000 on the Vickers scale. This makes them really good at cutting down wear and tear on parts like gears, hydraulic system components, and various sliding mechanisms where surfaces rub against each other constantly. After applying these coatings, some post treatment processes come into play too. Shot peening works by compressing those tiny surface grains which helps parts last longer when they experience stress over time. Tests show this can actually improve how well something resists breaking down from repeated loading by about 40 percent in things made from die cast aluminum like brackets and pivot points. For any component that faces ongoing friction, sudden impacts, or sits under high pressure fluids for extended periods, these kinds of surface improvements make all the difference between regular maintenance intervals and unexpected failures.

Ensuring long-term reliability through proper surface finish selection

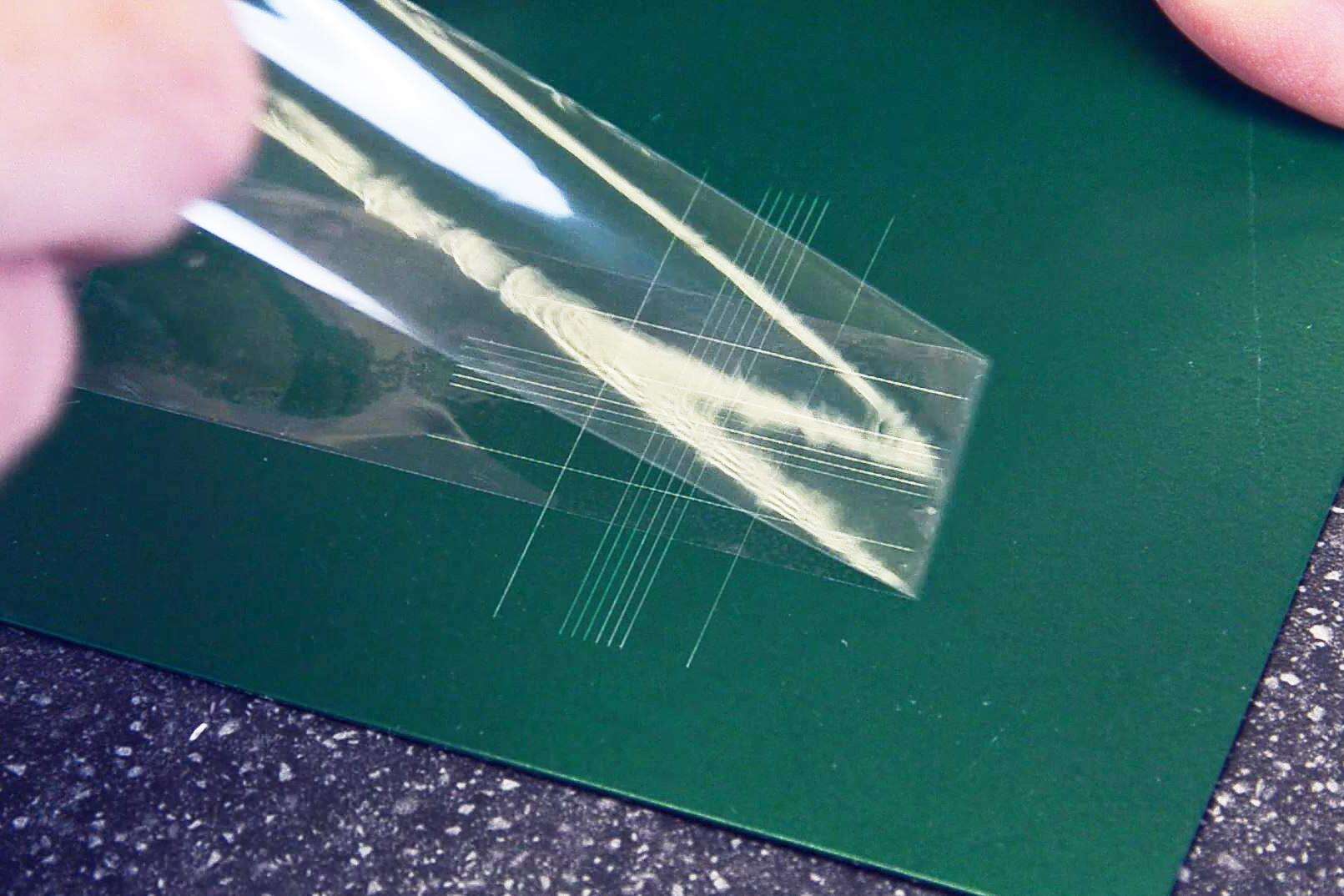

Choosing the right surface treatment according to what the equipment will face in real world conditions helps avoid early breakdowns. When it comes to electronic enclosures used outdoors, UV resistant powder coatings beat regular paint hands down when put through those thermal cycling tests specified in IEC 60068-2-14 standards. Surgical instruments made from stainless steel need medical grade passivation so they don't get damaged or discolored after going through countless cycles in the autoclave. There are several ways to check if these coatings actually work over time. Cross cut adhesion tests and the old reliable ASTM B117 salt fog test tell manufacturers whether their chosen finishes can stand up to both the weather and physical wear that happens day after day in actual service environments.

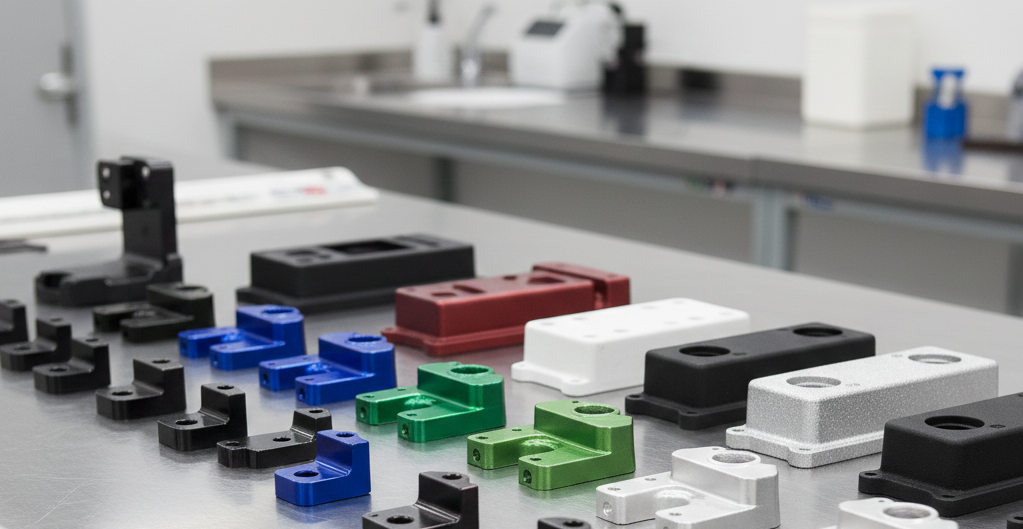

Anodizing and Powder Coating: High-Performance Surface Finish Options

Anodizing for Hardness, Aesthetics, and Corrosion Protection

The anodizing process creates a thick oxide coating on aluminum alloys such as ADC12 that can boost surface hardness by around 60% when compared to regular untreated surfaces according to research published in Material Science Journal last year. What makes this electrochemical treatment so effective is how it builds a protective shield against water damage and salt exposure, which means parts can withstand salt spray tests three times longer than before per ASTM standards. Another great thing about anodizing? It comes in different finishes from matte to glossy looks, plus colors applied during the process stay put much better than paint would. That's why we see it used extensively in car exteriors and gadgets where products need to look good while lasting through everyday wear and tear.

Powder Coating for Chip Resistance, Color Variety, and Uniform Coverage

When applying powder coating, we basically spray on a polymer resin using static electricity then bake it until it forms a protective layer between 2 and 6 mil thick. According to EPA data from 2024, this method gets around 95% transfer efficiency which means way less wasted material compared to traditional methods. Tests show it can resist chips about three times better than regular liquid paint when put through those Taber abrasion tests. There are actually more than 5,000 different RAL colors available plus all sorts of texture options too, so manufacturers can really match whatever look they need for things like outdoor machinery or building parts that have to stand up to weather. Plus there's no VOCs involved at all, making it compliant with environmental standards like REACH regulations without compromising quality.

Comparing Anodizing and Powder Coating on ADC12 and Similar Alloys

| Factor | Anodizing | Powder Coating |

|---|---|---|

| Coating Thickness | 0.5–25 µm | 50–150 µm |

| Corrosion Resistance | Excellent (1,000+ hrs salt spray) | Very Good (500–800 hrs salt spray) |

| Color Flexibility | Limited to metallic hues | Unlimited, including custom RAL |

| Cost Efficiency | Higher for small batches | Lower for high-volume runs |

Case Study: Automotive Die Cast Housings Using Anodized and Powder-Coated Finishes

A 2023 study evaluated 50,000 automotive transmission housings using anodizing on interior surfaces and powder coating on exteriors. Results showed:

- Anodized components: No corrosion after 18 months in humid environments

- Powder-coated exteriors: 85% reduction in UV-induced color fading versus painted surfaces

- The combined approach reduced annual warranty claims by 22% (Automotive Engineering Report 2023)

Chemical and Mechanical Pre-Treatments for Optimal Coating Adhesion

Chemical Conversion Coatings for Corrosion Inhibition and Paint Bonding

Zinc phosphate and chromate conversion coatings form microscale protective layers on die cast surfaces, improving corrosion resistance by up to 40% in salt spray environments compared to untreated alloys (Materials Protection Report 2023). They also enhance paint adhesion by creating a micro-textured substrate, reducing peel rates by 65% in automotive wheel applications.

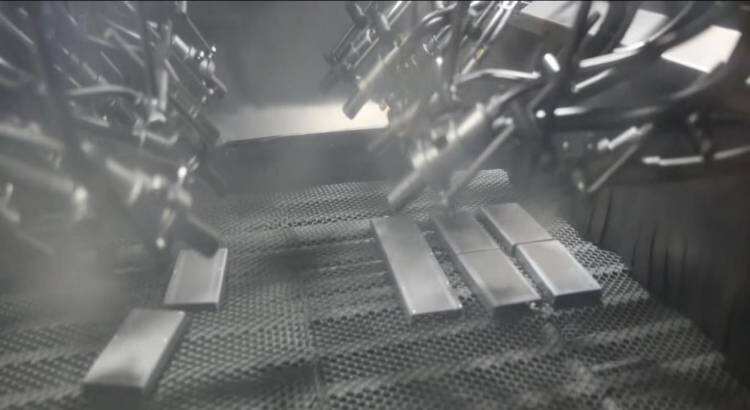

Shot Blasting and Sand Blasting to Enhance Surface Texture and Adhesion

Abrasive blasting with steel grit or aluminum oxide removes oxides and contaminants while generating a 2–5 micron surface profile. This preparation increases coating adhesion strength by 50–80% for powder-coated aluminum housings exposed to thermal cycling. A uniform surface roughness (Ra 1.5–3.2 µm) ensures consistent bonding across complex geometries.

Impact of Abrasive Finishing on Dimensional Accuracy and Surface Integrity

While aggressive blasting improves adhesion, maintaining ±0.05 mm tolerances requires careful media selection. Angular steel shot provides optimal texture with less than 0.3% material loss in high-precision zinc die cast parts. Surface integrity analysis indicates that blasting reduces subsurface porosity by 22%, decreasing potential crack initiation sites under mechanical stress.

Painting and E-Coating: Combining Aesthetics with Comprehensive Protection

E-Coating for Uniform Film Thickness and Full-Surface Corrosion Defense

E-coating, also known as electrophoretic coating, produces really consistent surface finishes. It applies thin films around 15 to 25 micrometers thick that actually work on complex shapes too. What makes this process stand out is how it gets into all those hard to reach spots and corners, which matters a lot for aluminum die cast components going into tough conditions like boats or outdoor electronic devices. Tests involving salt spray have shown these coated surfaces can last between 750 and 1000 hours before showing signs of rust according to some research from Ponemon back in 2023. That's about three times better than regular spray paint jobs. Plus, since nearly all the paint gets used during the process thanks to recycling baths, manufacturers find it meets those ISO 14001 environmental standards pretty well. And no one has to worry about drips or those annoying uneven edges that plague other methods.

Custom Painting for Brand-Aligned Aesthetics and Protective Color Finishes

To keep those vibrant colors looking fresh even after a decade under sun exposure, manufacturers turn to UV resistant pigments combined with top quality clearcoats. According to research published in the 2022 Automotive Finishes Study, parts painted with these special formulas maintain around 95% of their original shine after undergoing 5,000 hours of QUV testing which simulates harsh weather conditions. When it comes to applications like industrial pumps or medical equipment where appearance matters but safety is paramount, ceramic enhanced paints provide excellent protection against scratches rated at 3H pencil hardness level. Plus they meet all the necessary FDA requirements for surfaces that come into contact with products. Engineers really appreciate this combination of looks and longevity too. Recent data from Materials Performance shows that about 8 out of 10 engineers report being able to stretch the lifespan of components by roughly 40% when using these advanced coating technologies.

Selecting the Right Surface Finish Based on Application Requirements

Balancing Function, Environment, and Performance Demands

Getting the surface finish right means matching what the part actually needs to how it will be used in real world situations. For parts that need to handle heavy loads, wear resistant options such as hard coat anodizing work best in mechanical systems. When working near water, especially saltwater environments, the finish has to stand up against corrosion over time. Recent industry data shows around three quarters of all failed components had surface treatments that just didn't match their environment. When picking a finish, manufacturers should look at several factors including how well it sticks to the base material, whether chemicals present might break it down, and if it can handle temperature changes without degrading. These basics often get overlooked but make all the difference in component longevity.

Assessing Exposure Conditions: Salt Spray, Humidity, and Thermal Stress

Parts located in coastal areas or those coming into contact with road salt and de-icing agents really stand to gain from treatments like e-coating or chromate conversion coatings. These methods cut down on rust formation by somewhere around 60 to maybe even 90 percent compared to just plain metal surfaces left unprotected. When we talk about places where temperatures regularly go above 300 degrees Fahrenheit, ceramic based coatings tend to hold up much better than regular paint or other organic coatings when subjected to repeated heating and cooling cycles over time. And for facilities that need to control moisture levels precisely, powder coatings can be pretty economical choice as long as they're applied after proper phosphate cleaning processes, which helps them stick properly to the surface without peeling off later on.

Cost vs. Aesthetics in High-Volume Production of Custom Die Cast Parts

The anodizing process generally costs somewhere between fifty cents and a dollar twenty per part, although it usually saves money in the long run since there's no need for extra painting steps on things like car trims or electronic gadgets. When companies are looking at producing really large quantities, say over fifty thousand units, powder coating becomes the better choice financially speaking. It comes out to around thirty to eighty cents per item because it dries quicker and requires less manpower during production. Parts that aren't going to be seen by customers can sometimes get away with cheaper alternatives like sand blasting or applying chemical films instead. These methods still offer good enough protection while cutting costs by roughly forty to sixty percent compared to those fancy decorative finishes, so they work great for parts inside products where appearance doesn't matter as much as functionality does.

FAQ

What are the main types of surface finishes for die cast parts?

Common surface finishes include anodizing, powder coating, chemical conversion treatments, and e-coating. Each offers unique benefits in terms of corrosion resistance, wear resistance, and aesthetic appeal.

How does surface finishing affect the durability of die cast parts?

Surface finishing improves durability by providing protective coatings that resist corrosion, wear, and environmental damage. This extends the lifespan of parts, reducing maintenance and replacement costs.

Can surface finishes be customized for specific applications?

Yes, surface finishes can be tailored to meet specific application requirements by selecting appropriate materials, colors, and treatment methods. This ensures optimal performance and longevity under varying conditions.

What is the difference between anodizing and powder coating?

Anodizing creates a thin oxide layer on aluminum surfaces, offering excellent corrosion resistance and surface hardness. Powder coating applies a thicker polymer layer, providing superior chip resistance and color variety.

Are there environmental considerations in choosing surface finishes?

Many modern surface finishes are eco-friendly, using processes with low VOC emissions. Techniques like powder coating and e-coating often comply with environmental standards, making them suitable choices for sustainable manufacturing.

Table of Contents

- How Surface Finishes Enhance Die Cast Part Performance and Longevity

- Anodizing and Powder Coating: High-Performance Surface Finish Options

- Chemical and Mechanical Pre-Treatments for Optimal Coating Adhesion

- Painting and E-Coating: Combining Aesthetics with Comprehensive Protection

- Selecting the Right Surface Finish Based on Application Requirements

-

FAQ

- What are the main types of surface finishes for die cast parts?

- How does surface finishing affect the durability of die cast parts?

- Can surface finishes be customized for specific applications?

- What is the difference between anodizing and powder coating?

- Are there environmental considerations in choosing surface finishes?