Yadda Furofin Tsakiya Suka Ƙara Iyaka da Tsawon Abubuwan Da Aka Tsakawa

Ƙara kama da ruwan gudu a cikin abubuwan da aka tsakawa ta hanyar alhurru

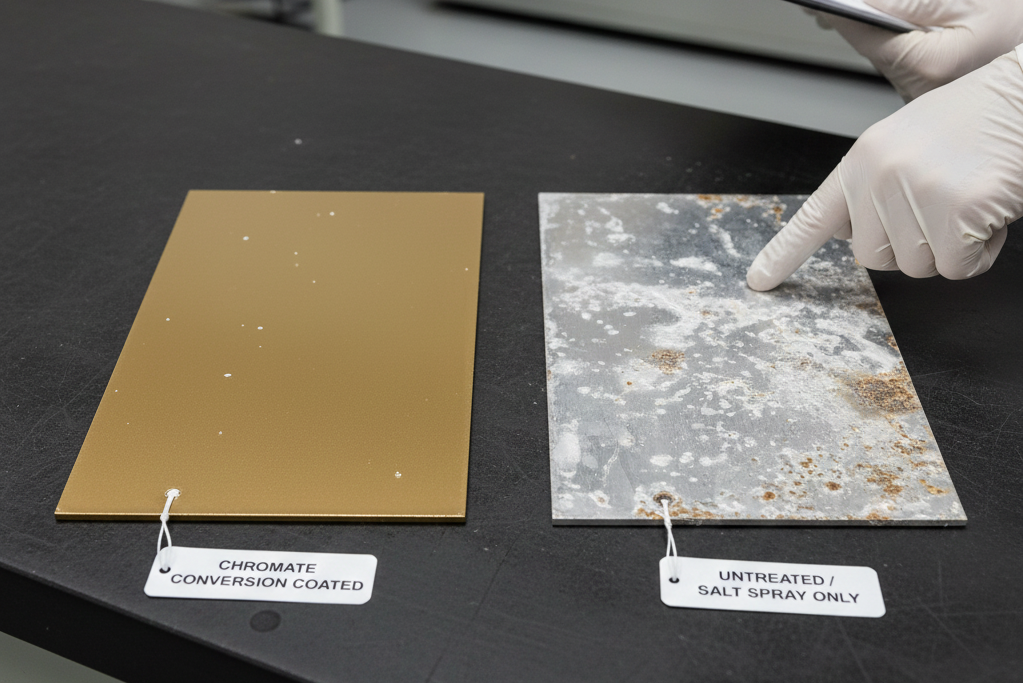

Alkawali da suka sha wani nau'in kimiyya da anodizing suna ƙirƙirar sharuɗɗan dakiwa dole don in kula da alwassami da zinc alloys daga dudun, tsakar gini, da kayayyakin dadi masu zurfi. A cikin takaitaccen bincike mai zabbar NACE International, afa amfani da chromate conversion coatings sun yi aiki karfe 500 awa a cikin testing na salt spray, wanda ya dangi game da 70% karanci ga abubuwan da ba su da wani nau'in aiki ba. Ilmin nukarin waɗannan ayyukan yana cikin ƙirƙirar sharuɗɗan oxide mai zurfi a shekarar molekulai ko amfani da kayayyaki da ke tura korosion. Wannan yana sa su samun amfani sosai wajen kula da batutu da ikwewa masu korosion a wuraren da hankuma suna hada da shada, idan shine zugu a saman mutum, kurumi a ruwan, ko kayan aikin da ake amfani da su a kasuwanci.

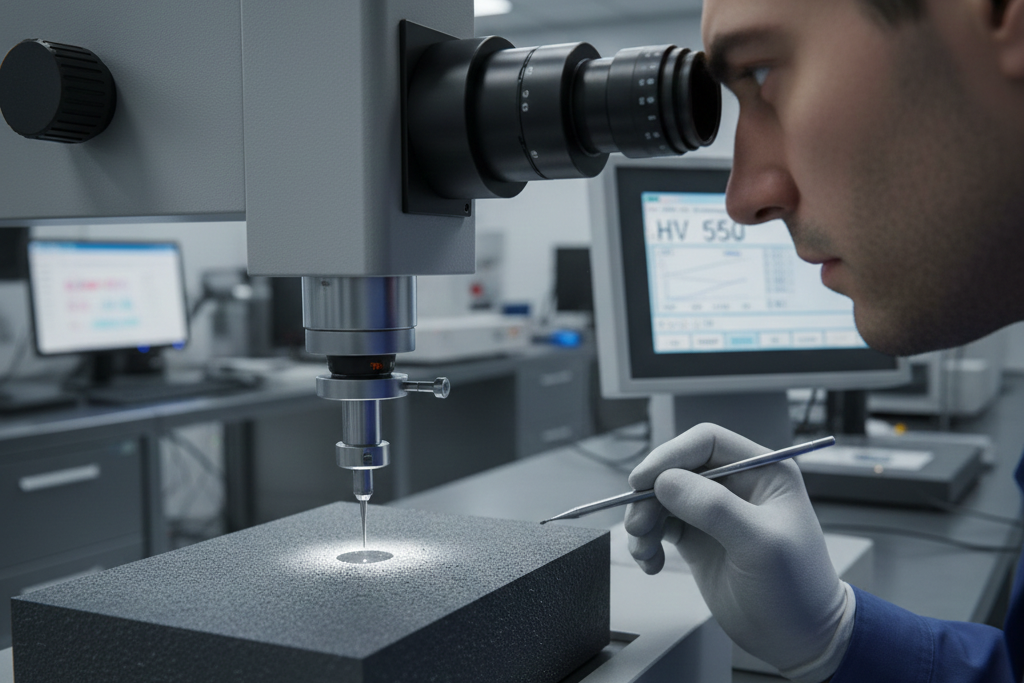

Karin kama da rashin kara da juzu'i na makiyya ta hanyar alkawali na aiki

Alkawari na yamma kamar anodizing mai zurfi da alkawari masu rage gishiri suna ƙara zurfin sama zuwa ga waje 1500-2000 a cikin skiman Vickers. Wannan yana sa suyi kyau don ruwan karfama akan kayayyakin kamar girde, kayayyakan tsarin hydraulic, da wasu hanyoyin zinzanyar da za suyan sama suna zinzanya da juna a karkashin lokaci. Bayan nemo wannan alkawari, wasu alhurufi na baya ana amfani da su. Shot peening ya yi amfani da compressing na wadannan tiny surface grains wanda ke taimakawa wajen yin abubuwan dauka fiye lokacin da sun karfe karfi a karkashin lokaci. Labarai suna nuna wannan zai iya inganta kyakkyawan wardawa game da koshin kuskuren loading ta hanyar takamaiman 40% a cikin abubuwan da aka tsara shi ne daga die cast aluminum kamar brackets da pivot points. Don duk wani abubuwan da ke face karfama mai zurfi, kuskure mai damu, ko zaune a karkashin fluids mai zurfi a karkashin lokaci mai zurfi, waɗannan nau'oi na abubuwan da aka goron gurdi suna ban sha'awa tsakanin ma'aikatai mai zurfi da kuskure mai damu.

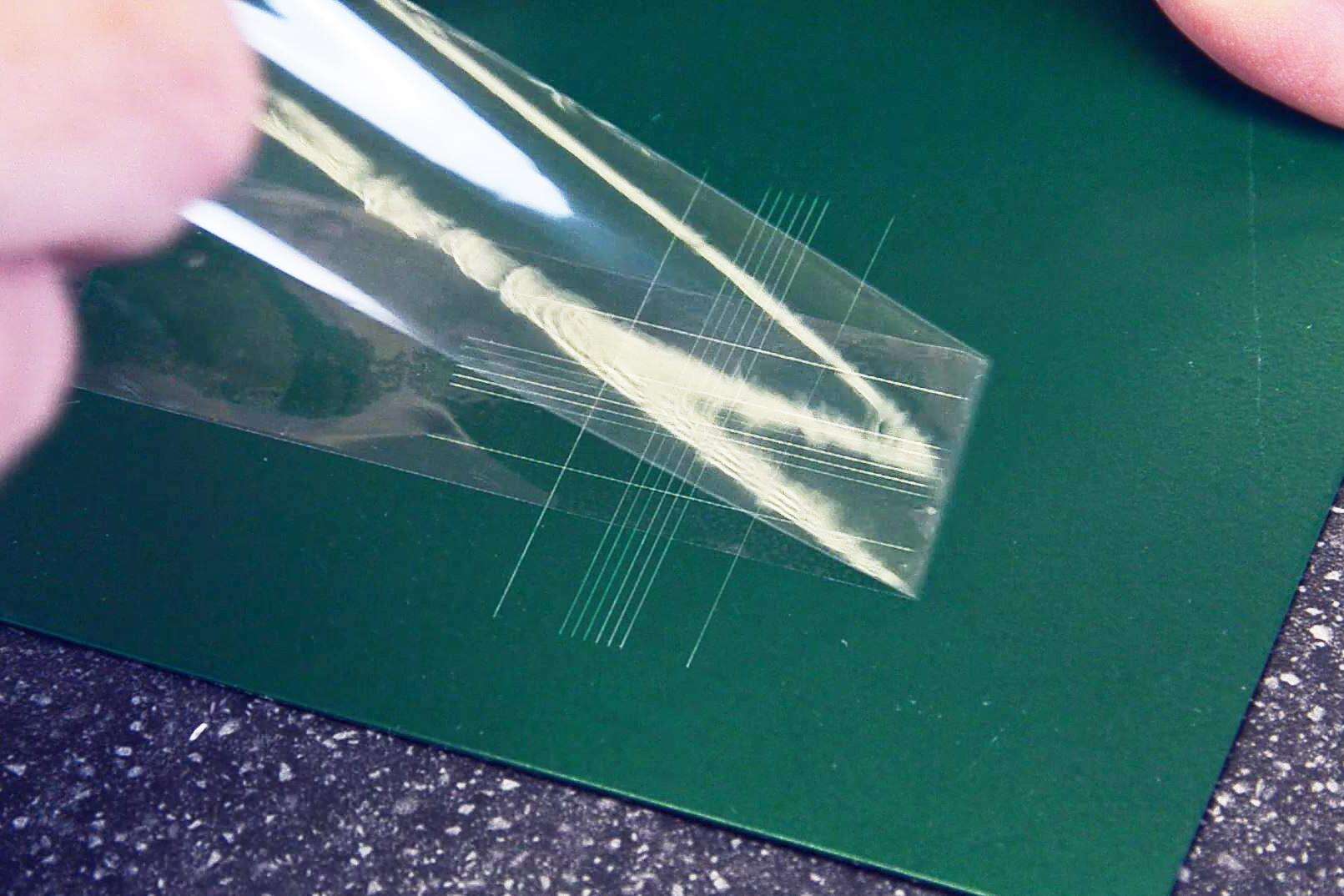

Samar da matsayin na'urar da ke ciki ta hanyar zabin inganci na kyakkyawa

Zabtar wayar daidaiton zaune bayan kama wanda abubuwan amfani zasu fuskantar a lokacin da ya dace, yana taimakawa wajen warware shafin rashin aiki zuwa. A yayin amfani da alakar elektoronik mai gudu, alaka mai tsangwama zuwa ga UV masu lafiya suna fi mafi kyau karomin waɗannan testa na thermal cycling wasuke suka shigar da IEC 60068-2-14. Alatun chirurgi made from stainless steel suna bukatar passivation na ingantacciyar tashoshin musamman domin kuwa ya kasance ko ya fara korozu ba dai dai ba ne sai dai yana shiga cikin autoclave kusan kusan kowanne lokaci. Ada biyu doka don duba idan waɗannan alakuka suna aiki a karkashin lokaci. Testa na Cross cut adhesion da testa mai tsada ASTM B117 salt fog suna nuna ma'amalata idan zaune da suka zaɓe suna iya tafia da yanayin zaman lafiya da rashin aiki wanda zai samu a karkashin amfanin abubuwan a lokacin da ya dace.

Anodizing da Powder Coating: Yanayin Zaune Masu Iƙatin Aiki

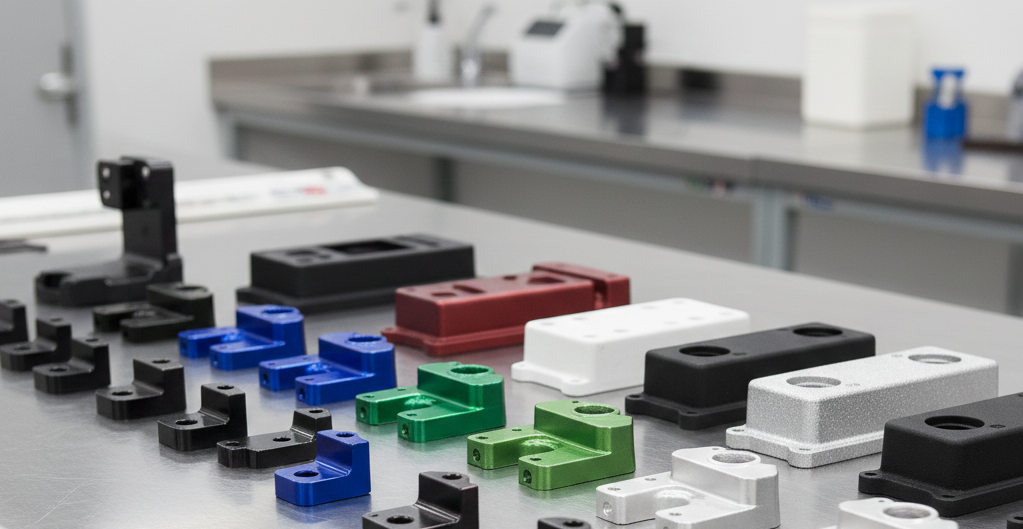

Anodizing don hardness, Aesthetics, da corrosion protection

Tsarin anodizing yana kirkirar alko mutum mai tsawon oxide a kan alloys na aluminum kamar ADC12 wacce tana iya hada da hardness na surface takamatau gaba daya 60% karshen sauke su na babban surface baya a wasu labarai da aka buga a Material Science Journal mabainan shekara. Wani abin da ke karkasa tsarin electrochemical na kyau ita ce yake kirkiri shield mai sauƙi don daki daga damage na ruwa da exposure to salt, wacce imaniyan abubuwan zai iya samun test na salt spray uku lokacin da kama da zuwa baya ayagun ASTM. Wani abin kyau game da anodizing? Tana da wasu nuni daga matte zuwa glossy, kuma launuka da aka yi a lokacin tsaro suna barin cikin kyau fiye da paint. Don haka mun ga ina amfani da shi a mahukunan kurta da gadgets inda abubuwan bayan dole ne su fara ko dai sai sun kasance saboda yawa.

Powder Coating don chip resistance, variety na launi, da uniform coverage

Idan kunna amfani da powder coating, mu san kuma mu fitar da polymer resin ta yare ta amfani da electricity sauƙi kuma mu kaɗawa shi har ya kasance tsarin wutar mai dabo bayan 2 zuwa 6 mil. Bayani na EPA daga shekarar 2024, wannan hanyar samun saurin yawan maɓallin gwiwa yana da kyau ga 95% wanda yake nufin rashin rashin abubuwa fiye da hanyoyin da aka amfani da su a baya. Labarai suna nuna cewa zai iya tafiyya gargadi uku lokacin da aka yi tests ta hanyar Taber abrasion tests. Har ma yana da yawa karshen 5,000 RAL colors da duk iyakokin texture, don haka masu amfani za su iya kauyata da wanne look su bukata ga abubuwan kamar takalamin na sama ko kayan gidaje da dole ne su tafi durum. Sai dai kuma babu VOCs da yawa, wanda ke nufin yanzu ya dace da standard na mahaliyar halitu kamar REACH regulations ba tare da kama’a kwalitinin.

Kima Anodizing da Powder Coating a ADC12 da alloys iri gaba

| Faktar | Anodizing | Powder coating |

|---|---|---|

| Coating Thickness | 0.5–25 µm | 50–150 µm |

| Juriya na Lalata | Murni (1,000+ hrs salt spray) | Murni Ga Yugan (500–800 hrs salt spray) |

| Zaure kan Warna | Yana dabe hanya zuwa kan fakwama mai launin buɗe | Babu kuduren, wanda ke baya RAL na iya bayarwa |

| Yadda Za a Yi Amfani da Kuɗi | Talla sosai ga alaƙa mai yawa | Talla ƙasa sosai ga alaƙa mai yawa |

Tace Kudi: Gida ta Fasaha na Iyara Mai Anodized da Powder-Coated Finishes

An yi goyon shekara na 2023 a karkashin 50,000 gida ta iyara suke amfani da anodizing a samaun daufi da powder coating a waje. Alamar da aka samu sun shafi:

- Abubuwan da aka anodize : Babu korosi bayan 18 kwanan wata a cikin albarkatu masanya ruhu

- Samaun da aka powder-coat : 85% tonkwarshe a cikin launin fading due to UV dibé bisa samaun da aka rubuta

- An samun kowane shekara da aka daina wasan gwamnati ne ta 22% (Raputa Ilmin Ukuwa na Otomatik 2023)

Alkimi da Fassara Na Kima aƙalla Don Tsinkaya Mai Kyau

Tsinkin Alkimi don Kare waɗa Guduwa da Haɗin Waya

Tsankan zinku phosphate da chromate sun yi tsankan goyon gurji kan yarjejeniyoyin die cast, suka ƙare guduwa ta hanyar 40% a cikin tafiya mai salt spray dibu da alloys da ba suwa an farawa (Raputa Kare waɗa Guduwa 2023). Sun kuma ƙara haɗin waya ta hanyar ƙirƙirar substrate mai goyon goyon, sun daina nisbi na pull down ta 65% a cikin amfani da ukuwa na otomatik.

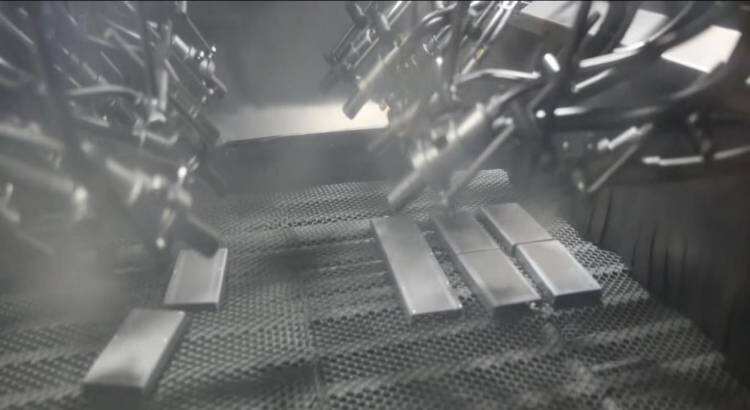

Tushen Shot da Tushen Sand Don Kama da Daidaiton Surface da Haɗin Waya

An ganye da grit na fasudi ko aluminum oxide yana cire wasan kankanta da aljibba yayin da ke tsara takamaiman surface na 2–5 micron. Wannan tsaro yana ƙara tsarin kashin kwaliti ta hanyar 50–80% ga alabbarin aluminum da aka sauya da sauya zuwa tazara. Takamaiman roughness (Ra 1.5–3.2 µm) yana bada kama da wuri a karkashin kayan aikin da suka dace.

Tasirin Abrasive Finishing akan Tattalin Arzikin Jeri da Ingancin Surface

Idan kuma harshen ganye zai kara kama, sai dai kuma dole ne a yi zaɓi mai zurfi don zama tsakanin ±0.05 mm. Grit na fasudi na angular yana baɗawa madaidaui mai kyau tare da kurcin abubuwan kamatawa da wayar 0.3% a cikin kayan aikin zinc die cast masu inganci. Lissafi na ingancin surface yana nuna cewa ganye yana kara porosity na farko ta hanyar 22%, kuma yana kara wuraren da za a barzuwa a lokacin da aka iya amfani da shi.

Gwaji da E-Coating: Haɗawa Kyakkyawan Lahira da Kafa Mai Daidaito

E-Coating don Takamaiman Film Thickness da Kafa Mai Kyau

E-coating, wanda a known shi da electrophoretic coating, yana produce wasan surface finish mai dacewa. Yana nuna alamar kara daidai game da 15 zuwa 25 micrometers inda ke aiki akan yanayin complex a cikin. Abin da ya haɗa wannan proses shine yanzu ya fito cikin duk wadannan wuraren da aka susa da kunsu, wanda ke mahimmanci sosai ga abubuwan aluminum die cast da suke shiga cikin halayyin gudu kamar kayan takaloli ko kayan elektronik na gabas. Labarai da suka yi testa tare da spray na salt suna nuna cewa waɗannan galviji masu coating zasu iya samun karshen lokaci game da 750 zuwa 1000 hours kafin su nuna alamar rust saboda ra'ayin Ponemon a 2023. Wannan ita ce uku shekaru babba dai ne akan irin paint spray na musamman. Sai kuma, saboda dukin gaba daya na paint take amfani da a cikin proses yayin da aka amfani da abubuwan da za a iya sauya, masu tsaro suna ganin cewa wani ya ci gaba da standard din ISO 14001 na environmental law. Kuma babbu zai buƙata shaƙawa game da dripping ko wadannan kunsu mara kyau da suke juyawa wasu hanyoyin.

Custom Painting don Brand-Aligned Aesthetics da Protective Color Finishes

Don hana waɗannan launanan albarkatu suka hada kamar yadda suke samuwa kuma bayan shekaru goma a cikin rayuwar solace, masu amfani suna amfani da alkaru mai daidaiton UV wanda aka haɗa da alkaru mai kyau. Bayan bincike da aka buga a 2022 Automotive Finishes Study, abubuwan da aka nuna alkaru tare da wannan nau'in formula sun tsaya kamar 95% na shine original su bayan karfe da 5,000 sa’a a cikin testar QUV wanda ke nuna halayyin agara mai tsoro. A cikin amfani kamar pump na sarari ko kayan aiki na tabbatacciyar tushen iyali inda zamantakewa ke da mahimmanci amma tsaro ita ce babban muhimmi, alkaru masu ceramic suna baƙin maimakon mai zurfi don kullewa wanda aka oda shi ne a 3H pencil hardness level. Kuma suna tabbatar da duk wadansu ma'auni da za su barcin FDA ga dabam-daban da za su faru da kayan aiki. Masu iya ranar wannan haɓaka na zurfi da tsinkin shekara. Lura da bayanai na gabaɗayan daga Materials Performance, yanzu 8 daga cikin 10 malamai suna nuna waɗansu iya kara tsinkin shekarar abubuwan ta kama da 40% lokacin da suke amfani da wadannan teknologijin coating na musamman.

Zaɓi Na Tsarin Taimakawa Ta Hanyar Abubuwan Da Ake Saba Da Su

Nemo Iko, Duniya, da Abubuwan Da Ake Buƙata Ga Alhali

Wani abu ne mai mahimmanci wanda yake nuna cewa abubuwan da ke dawo da wani hali suna da wani irin taimako. Ga abubuwan da ke buƙatar kai tsananin girman gini, abubuwan da za a iya amfani da su kamar anodizing na musamman suna da kyau a cikin tsarin makinar. Lokacin da aka yi alkawari da ruwa, kafin ruwan kankara, taimakon dole ne ya tsammi da rashin zurfi. Bayanin sarayen zamani na nishadi yana nuna cewa takamaten uku na biyu na duk abubuwan da suka fallasa suna da taimako wanda bai dace da duniyansu ba. Lokacin da aka zaɓi taimako, masu amfani dole ne su duba wasu abubuwan kamar yadda zai haɗa da kayan aiki, idan wani chemical zai iya wara shi ko zai iya tafi da canjin har zuwa ba zai zurfin ba. Wadannan abubuwan bazuwa suna da mahimmanci amma suna da kyau a cikin karin shekarun abubuwan.

Gwadawa Kafin Tabbatar da Shuka: Gishiri, Ruhun Ruwa, da Daidaiton Haliyar Harshen

Abubuwan da ke kusurwa a yankuna masu gishiri ko abubuwan da suka wuce da gishiri na hanyar lantarki da abubuwan da ke tsada ruwa suna da amfani sosai da tacewa kamar e-coating ko chromate conversion coatings. Wasu hanyoyin waɗannan suna kare haɓakar gishiri ne aƙalla daga 60 zuwa kusan 90% dibé sai dai abubuwan da ba su karfi ba. Lokacin da muna yi imanin wuraren da kyakkyawan harshen ya tafi 300 daraja Fahrenheit, coatings na ceramic suna samun harshen mai zurfi fiye da wani garba ko wasu coatings na organic lokacin da aka shigar da su zuwa cikin sashin saukewa da zama mai zurfi a karkashin lokaci. Sai kuma ga alajjabuna da ke bukata gwada ruhu na ruwa, powder coatings zai zama zafi mai kyau idan an nuna shi bayan maye phosphate cleaning, wanda yake taimaka wajen kara shi sama da surface ba za a rinka kasance ba.

Makera da Nahawa a Production Mai Yawa na Custom Die Cast Parts

Tsarin anodizing yana kuma makada wataƙila goma shidda zuwa gomani biyu per part, amma yana kuma tafiya kudaden cikin rungume saboda baya bukatar idan adduwa akan abubuwan kamar cuta na otomatik ko abubuwan elektoronik. Lokacin da shagoji suna duba daga cikin yin wadansu abubuwan da suka fi gomani ishi jiragen, tsarin powder coating yana zama aƙalla kyauta cikin ilmin kuɗi. Yana zama gomani goma zuwa gomani shidda per item saboda yana buru sauke kuma yana bukatar abokan hannu mai karanci a lokacin yin abu. Abubuwan da ba za su ka gama mataimakin masu siyan ba suna iya samun hanyoyin mai irin sassa ko amfani da filamin kimiya pito. Wadannan hanyoyin suna bada lafiyar kansa mai zurfi yayin da ke rage kudaden ta hanyoyin takaitaccen adduwa ta hanyar arzikin gomani shidda zuwa gomani shepuna, don haka suna yi aiki mai kyau ga abubuwan cikin abubuwan da kayayyakin ba ya dace sosai kamar yadda ake so.

Tambayoyi Masu Yawan Faruwa

Wanne ne ma'anar nau'ikan adduwa na surface finishes don abubuwan die cast?

Za suka hada da anodizing, powder coating, chemical conversion treatments, da e-coating wasu dabi'un da za a iya samun su. Kowanne yake ba da alhali mai tsawo game da kare wa tsinkaya, kare wa tushen, da kyakkyawan nuna.

Yaushe surface finishing ke yin tasawa ga tsarin abubuwan die cast?

Surface finishing ke ƙara tsayin yawa ta hanyar bawa alamar wadda ke kare wa tsinkaya, tushen, da saukin dutsen bayan. Wannan ke kara yawan shekaru da abubuwa suna dura, sannan ya kama da mara biyan sigara da canzawa.

Shin za a iya yi tsari ga surface finishes don ma'amalin da aka ambaci?

Ee, za a iya tsarin surface finishes don dawo da bukatar ma'amala ta zabin kayan aikin, launi, da hanyoyin aiki. Wannan yana kama da aiki mai zurfi da tsayin yawa a cikin halayyin magana.

Wanne ne farken baya tsakanin anodizing da powder coating?

Anodizing yana kirkirar layi mai zurfi mai sauƙi a kan aljabrici, tare da kama'ulat gafara da zurfi na sarauta. Yankin powder coating yana nuna layi mai zurfi, tare da kama'ulat gafara da dutsen launi.

Shin akwai abubuwan da ke bukata ingancin yankin ganyaya a zabin ganyayen sarrafa?

Alabaƙin ganyayen sarrafa masu zaman kansu suna da alkaruwa, suka amfani da tsari da ke iya ƙasaƙoƙin VOC. Hanya kamar yankin powder coating da e-coating yana daidaitawa da ma'auni na alkaruwa, sannan suna zabi mafi kyau don kirkirar da ke da alkaruwa.

Teburin Abubuwan Ciki

- Yadda Furofin Tsakiya Suka Ƙara Iyaka da Tsawon Abubuwan Da Aka Tsakawa

- Anodizing da Powder Coating: Yanayin Zaune Masu Iƙatin Aiki

- Alkimi da Fassara Na Kima aƙalla Don Tsinkaya Mai Kyau

- Gwaji da E-Coating: Haɗawa Kyakkyawan Lahira da Kafa Mai Daidaito

- Zaɓi Na Tsarin Taimakawa Ta Hanyar Abubuwan Da Ake Saba Da Su

-

Tambayoyi Masu Yawan Faruwa

- Wanne ne ma'anar nau'ikan adduwa na surface finishes don abubuwan die cast?

- Yaushe surface finishing ke yin tasawa ga tsarin abubuwan die cast?

- Shin za a iya yi tsari ga surface finishes don ma'amalin da aka ambaci?

- Wanne ne farken baya tsakanin anodizing da powder coating?

- Shin akwai abubuwan da ke bukata ingancin yankin ganyaya a zabin ganyayen sarrafa?