Kedu ka Ndịdịta Gburugburu Nyere aka Mmetụta Die Cast Nyere Obodo na Obodo

Nhazi corrosion resistance na mmetụta die cast site na nhazi gburugburu

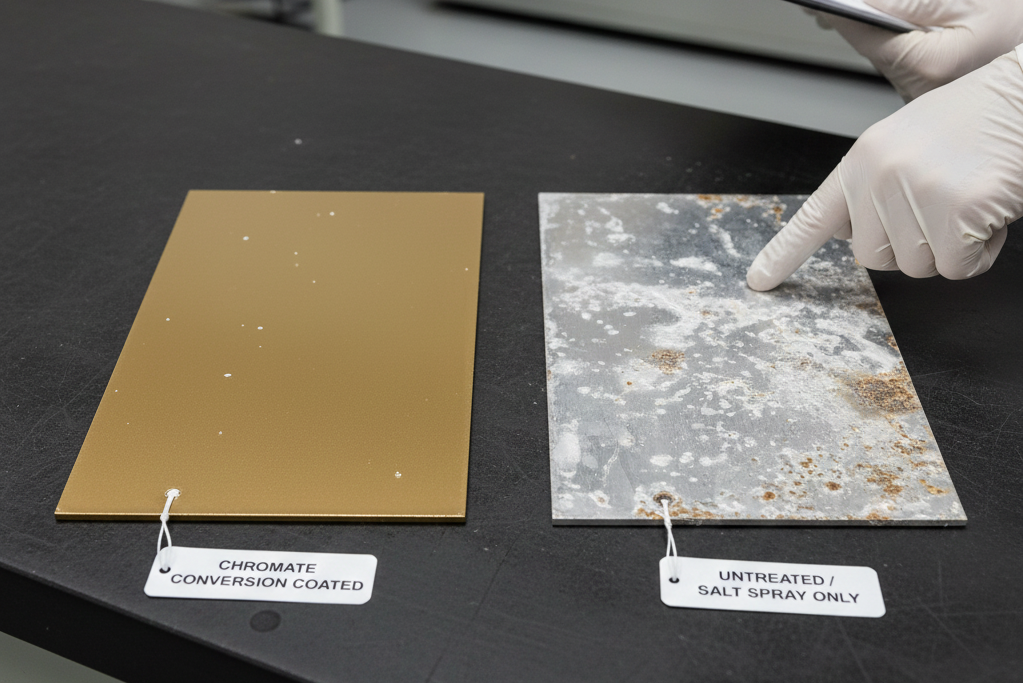

Ihuenye dị ka ihe ọrụ kemịkalụ na anodizing mere akpụkpọ ntụpọ nke mkpa ka ebechemaka aluminiom na zinc alaọnye si nchekwa ya site na mmụba, mmiri osimiri na ihe kemịkalụ ndị dabere. A na-ezukọrị NACE International gara aga maka ọdịnala aluminiom nke e mere ihuenye chromate siri ike karịa 500 awa na ngwakọta osimiri, nke pụtara 70% karịa ihe ọkụ ahụghị ihuenye. Iwu nke ihuenye a bụ ime akpụkpọ oksịd dị nnukwu na elu atọmụ ma ọ bụ ime ihe nwere ike iburuburu ikpo mkpụmkpụ. Nke a na-enyere aka ịgbagharị ihe omume dị ka ikpo mkpụmkpụ na ikpo galvanic na mpaghara ndị ebe mmiri na-emekarị, dị ka n'ime ụgbọ osimiri na osimiri, ụgbọ ala na rọda ma ọ bụ egwuregwu nke e jiria na ụlọ ọrụ.

Nnweta okirikiri na mmetụta mebebi site na inweta ihe nkiri

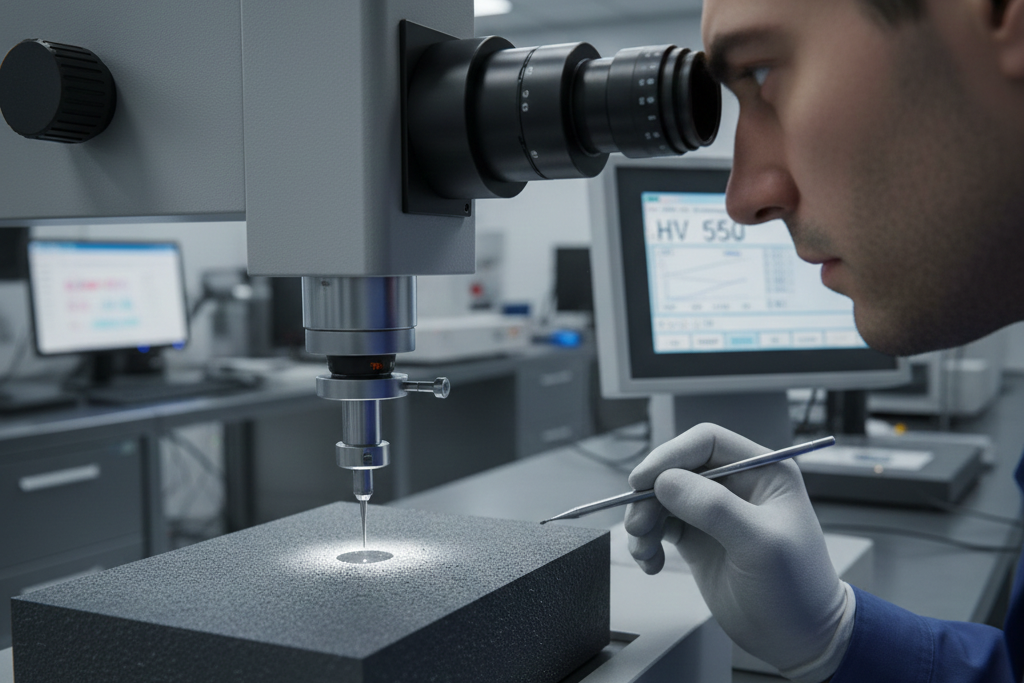

Nsona ụba dị ka anodizing hard coat na ceramic coatings ezipụrụ n'agbụsị nyirisi ike ụba gaa na 1500-2000 na skel Vickers. Nke a na-enyere ha ike ịdị irè maka nweta ozi na ngwaọrụ dị ka egwuregwu, ngwaọrụ sistem hydraulics, na ụfọdụ ngwaọrụ mkpụmkpụ nke akụkụ siri ike na-anweta ya mgbe ebighị ebi. Mgbe e mere nsona ụba a, ọnụọgụghị post treatment process dị iche iche. Shot peening na-arụsi ike site n'ịmepụta akụkụ njọ ndị aja aja nke na-enyere aka maka ịdị irè karịa mgbe ọ na-eji ike. Mmiri amata na nke a nwere ike imejụta otú okenye emebi emebi site n'ọnụọgụghị 40 percent na ngwaọrụ e ji aluminum die cast mee, dị ka brackets na pivot points. Maka ngwaọrụ ọ bụla nke na-ahụ maka friction, ahụike ahụike, ma ọ bụ dị n'okpuru fluids nke ike ukwuu mgbe niile, nsona ụba ndị a bụ ihe kachasị mgbakwansi gbasara ntụgharị mmadụ na-adịghị adị.

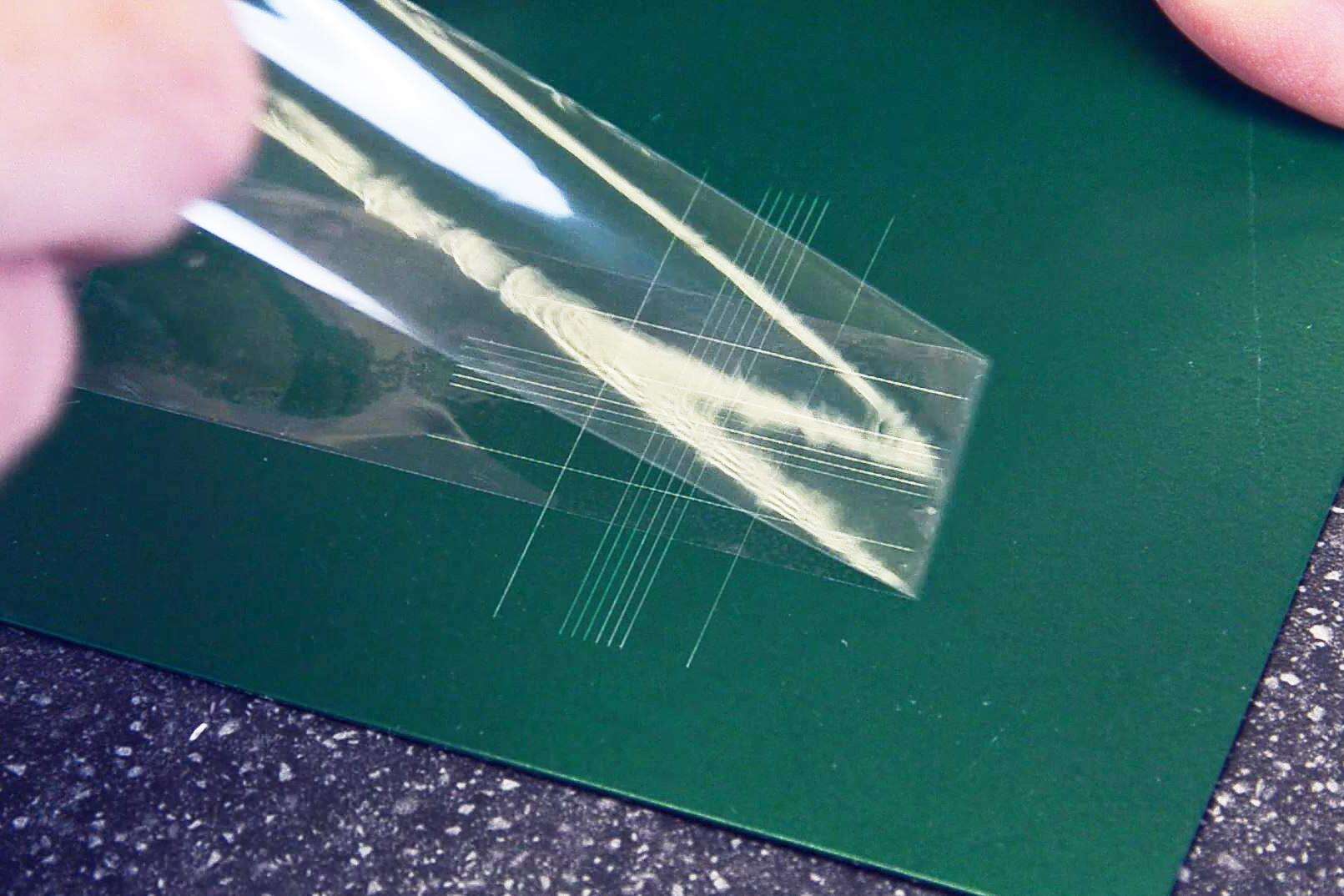

Ịnweta ezigbo ohere nke ịkpọpụta akpa maka ịdị n'ofe na-adịghị mgbu

Ịhọrọ mmepụta akpa dị mfe maka ihe ọma ga-eme n'ime obi ike na-amalite mbupu mgbe eji ya. Mgbe ekwesịrị ihe ngagharị elekere nke na-esi n'elu ụra, mpemọr akpa nke na-enwe ivu UV bụ otu n'ime ndị pere mpe karịa akpa ọma mgbe eji ha weghachite na njikọ isi nke IEC 60068-2-14. Njikọ ọrụ nke stainless steel chọrọ passivation nke medịsịn ka ọ ghara ịdịgbe ma ọ bụ ịdị ọcha mgbe eji ya na autoclave n'ụbọchị. O dị iche iche ụzọ iji mezuo otu ka mpemọr akpa a na-ebeda mgbe ebili. Ndị na-akpọ cross cut adhesion tests na ASTM B117 salt fog test na-ezike onye nnweta otu ka akpa ha chọrọ na-enweghị ivu ma ọ bụ na-enweghị igwe nke na-agbanwe agbanwe n'obi ike nke na-esi n'ụbọchị.

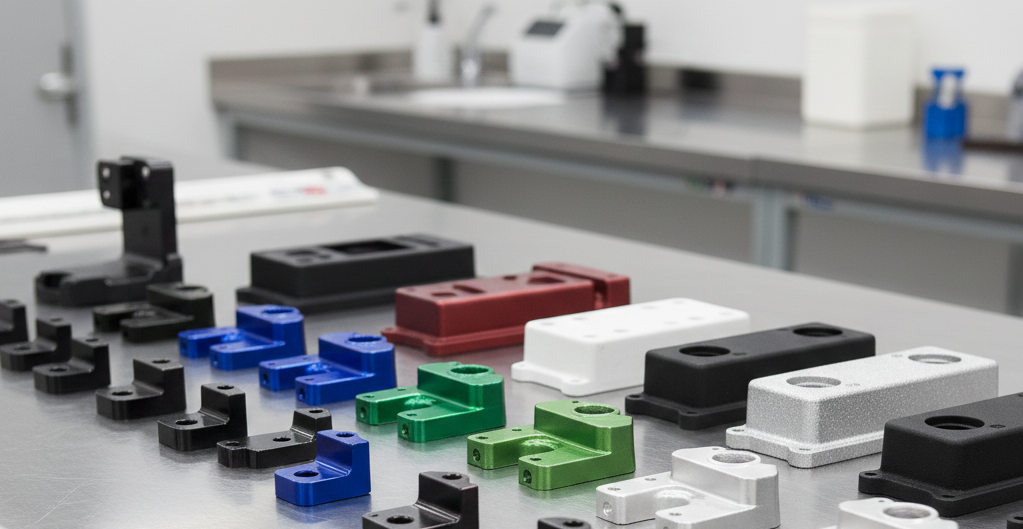

Anodizing na Powder Coating: Ndị pere mpe nke ịkpọpụta akpa

Anodizing maka Ihe Mgbawa, Mmetụta na Ịdị Ọcha n'ihu

Ihe ọrụ anodizing kerepụta ihe mgbawa oxide dị nnukwu na alloys aluminum dị ka ADC12 nke pụtara ịdị mgbawa n'ihu site na 60% karịa akụkụ agha agha gbasara akụkụ agha agha dịka e mere na afọ gara aga n'akụkụ Material Science Journal. Nke makarịrị ihe ọrụ electrochemical a bụ na ọ kerepụta mpụga nkịtị nke na-egbu egbu maka mmiri na njedebe, nke pụtara na akụkụ nwere ike ibanye oge test spray salt atọ karịa mgbe efu efu gburugburu ASTM. Ihe ọzọ oma maka anodizing? O dị na mbipute dị iche iche ruo mgbochi, ma ọ bụ agwa dị na prosesị ahụ dabara karịa paint. Ya mere bụ isi iji ya n'ime ntụrụndụ ala na gadgets ebe produk nwere ike ime ka ha dị mma mgbe ọ na etiti ọrụ ndụ.

Powder Coating maka Ịdị Ọcha n'ihu, Ọnụọha Agwa, na Ịdị Ọcha n'ihu

Ọ bụrụ na ị na-atinye akpụkpọ, anyị na-egbu egbu ya n'ime resin polymer site electrostatic wee gbawaa ya mgbe o ghara ibufe akpụkpọ dị mkpa otu 2 na 6 mil. Gbasara edemede EPA site na afọ 2024, usoro a na-eweta ike ọkụ nke 95%, nke pụtara na ọ dị ala karịa ihe ndị a na-eji maka usoro nlegharị ala. Iwu gosi na ọ na-enweghị mgbawa nke ukwuu iri atọ karịa akpụkpọ akpụkpọ obi banyere mgbe ị na-eji ụzọ Taber imebi. E nwere RAL ọnụ ọgụgụ karịa 5,000 dị iche iche, ma ọ bụ ụdị dị iche iche, ya mere onye ọrụ na-enyere ike ịdị ya otu esi dị ka ha chọrọ maka ihe dị ka mesin na agwa ebe obibi nke chọrọ ịdị n'ihu mmiri. Nke ọzọ, ọ dịghị VOC kasịmere, nke mere ya na-agba ume na standima ihe nketa dị ka ndepụta REACH n'agbata ogologo mmadụ.

Ịgbu Anodizing na Powder Coating n'ime ADC12 na alloy ndị ọzọ dị ka ya

| Factor | Ịgba anodizing | Coating akwụkwọ |

|---|---|---|

| Ogologo akpụkpọ | 0.5–25 µm | 50–150 µm |

| Corrosion Resistance | Ọ dị mma (1,000+ awa salt spray) | O dị mma (500–800 njeremgbochi mmiri onu ocha) |

| Njikọtara Agwa | Naanị agwa metalikụ | Onweghị mbipụta, na-agbakwụnye RAL dị otú i choro |

| Ịdị Irè n'Imefu Ego | Oke karịa maka akpụkpọ ndị nta | Ọda karịa maka akpụkpọ ndị zuru oke |

Akwụkwọ Nchịkọta: Ngwakọta Die Cast Mmiri Na-Enwe Ebe Anodized na Ngwakọta Powder-Coated

Nchịkọta 2023 amalite 50,000 ngwakọta transimison miri na-anweta anodizing na ebe ahụ dị n'ime na ngwakọta powder na ebe ahụ dị n'aka ekpe. Akụkọ edebere:

- Ngwakọta anodized : Onweghị ikpo mgbe ebili na asaa afọ na ebe ndị dị n'ime mmiri

- Ọkụlọ na-efe efe akụkụ ahụ : 85% nwaghachi nke mmiri ahụ dị mkpukpu n'akụkụ ahụ karịa akụkụ na-efe efe

- Ndaba a zuru oke rụchara aka mbupu anaghị egosipụta iwu 22% (Akụkọ Ihe Jikọtara Mmiri Nkebiokwu 2023)

Ihe Ndị Dị Otú Chemistri Na Mekanik Iji Mee Nkwado Karịa Nke O Di Ulu

Ihe Ndị Dị Otú Chemistri Iji Mbutu Korosion Gbara Na Mbupu Akụkụ Ahụ

Zinc phosphate na chromate conversion coatings mere akụkụ mmiri dị n'akụkụ die cast, na-enyere aka ịdị elu nke resistance korosion site na 40% n'ime obodo mmiri ochie dibaa dibaa karịa alloys ndị amaghị ihe (Akụkọ Ndị Mbutu Materials 2023). Ha na-enyere aka mbupu akụkụ ahụ site na ime akụkụ dị irè, na-eme ka oghorowanye 65% n'ime ngalaba akụkụ mmiri nkebiokwu.

Ịkpụ Ọkụla Na Ịkpụ Akụkụ Iji Nyere Aka Akụkụ Na Mbupu

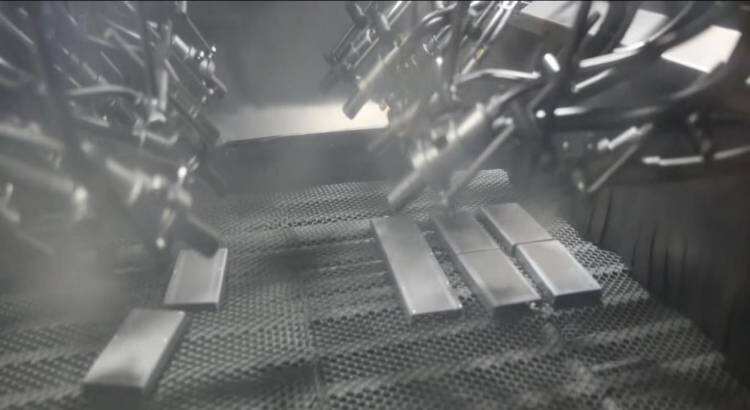

Ịkpụkwa n'ime odu mmiri na-eme ka grit oji ma ọ bụ aluminum oxide wepu oxides na contaminants mgbe ụfọdụ na-eme mkpuchi a na-akpata 2–5 micron surface profile. Ndị na-emegbu a na-enwe akụkụ nkịtị maka powder-coated aluminum housings e mesịrị na thermal cycling siteere 50–80%. Mkpuchi dị otu (Ra 1.5–3.2 µm) si dị aka ike imebele na-adaba adabere na geometries dị iche iche.

Mkpa nke Abrasive Finishing na njikọta akụkụ na njikọta akụkụ

Dịka ịkpụkwa dị egwu na-enyere aka mee akụkụ, ịkpachara ±0.05 mm na-achọkarị usoro na-enye ngwaọrụ. Steel shot angular pụtara texture zuru oke na-abịa n'elu 0.3% material loss na zinc die cast parts dị elu. Anaalysisi njikọta akụkụ ekpughe na blasting na-ewepụ subsurface porosity siteere 22%, na-eme ka e wepụrịrị ụzọ crack initiation sites n'okpuru mechanical stress.

Ịgbapụta na E-Coating: Meezie obi na njikọta aturu aturu

E-Coating maka film thickness dị otu na njikọta corrosion aturu aturu

E-coating, a maara dị ka electrophoretic coating, na-enye akụkụ oke ike nke ọma. O na-enye akụkụ iri na ise ruo iri na abụọ na anọ micrometers nke pụrụ iche na akụkụ dị mkpa. Nke a na-emekarịrị bụ na ọ na-abịa na mpaghara niile ndị dabere ma ọ bụrụ na ngagharị, nke dị mkpa maka ụkpụrụ aluminum die cast ndị na-egepịta ya na oke oshinamọnụ dị ka mbu mmiri ma ọ bụ ngwaahịa elekereekere na agwa. Iwu salt spray gosipụtala na akụkụ a na-achọghị ya iri na ikwèrè ruo iri na ntọ afọ jamvebe mgbe ọ na-egosi ọsọsọ nkwarụ n'afọ 2023 site na Ponemon. Ndị a bụ atọ otu mgbe karịa akụkụ spray paint nke obere. Ya mere, site na usoro ọdịnaya, eji otú ụba ahụ n'oge usoro n'ihi na eji ya achọpụta, onye ọrụ igbe na-ahụ na ọ na-arụ ọrụ n'usoro ISO 14001 nke ọma. Ma ọ bụrụ na enweghị ihe ịbụrụ n'ime egwu ma ọ bụrụ na enweghị akụkụ dị ajụjụ ndị na-ebute ya.

Akụkụ Mmekọrịta maka Akụkụ Brand-Aligned na Akụkụ Onyonyo Mmekọrịta

Iji chekwaa ụtọ ahu ndị a dị ụtọ ezigbo njem ebe ebili na afọ iri na agụmakwụkwọ n'ime anu, onye ọrụ ahụ na-agbakwunye ngwaọche UV na akwukwo akpụkpọ echichi dị mma. Gbasara ihe ọmụmaụ na-akpọkarị na 2022 Automotive Finishes Study, ngwaọrụ ndị a na-akpụ akpụkpọ akpụkpọ ahu pụrụ iche pụrụ iche nwere ike imejụta 95% nke ụtọ ha gara aga mgbe ha na-achọpụta QUV site na awa 5,000 nke na-enyere ha ikike ịmeli oshiwu nzuzo. Mgbe ị na-ezo aka na ngwaahịa dị ka pom nke na-emepụta ahụmahụ ma ọ bụ ngwaahịa medịkọ nke eziokwu dị mkpa mana mmegbu dị mkpa, akpụkpọ akpụkpọ ceramic na-enye ntaramahụhụ pụrụ iche pụrụ iche maka mbubata dị ka 3H pencil hardness level. Nke ọzọ, ha na-arụ ọrụ mgbe niile FDA arụmọrụ maka akpụkpọ ndị na-ekpata ngwaahịa. Onye nnukwu ngwaọrụ karịrị nke a na-achọpụta ihe ndị a. Datta ọhụrụ gbasara Materials Performance na-akpọ na 8 n'ime 10 onye nnukwu ngwaọrụ na-akpọ na ha nwere ike ime ka oge ọrụ ngwaọrụ dị elu site na 40% mgbe ha na-eji teknụzụ akpụkpọ ndị a.

Ịhọrọ Ọkpụkpọ Ọdịdị Ebe Gbasara Ihe Nkiri

Balancing Function, Environment, and Performance Demands

Igosi na ọkpụkpọ ọdịdị ebe dị mma pụtara iresi ihe a ga-eji ya mee n'ime oghere ndụ. Na ngwaọrụ ndị kwesịrị ime ka ọ dịkarịrị, ihe ndị dị mma karịrị dị ka hard coat anodizing bụrụ otu n'ime usoro mekanik. Mgbe ị na-arụsa ike n'akụkụ mmiri, na mpaghara mmiri osimiri, ọkpụkpọ ahụ ga-eme ka ọ kwalite ikpochapu. Dabere na edemede ndị n'ime ndị na-arụ ọrụ, e mere ka ụmụ ato na abụọ n'ime ngwaọrụ niile ndị emechitela adịghị na-adaba na mpaghara ha. Mgbe ị na-ahọrọ ọkpụkpọ, onye nrụpụta ga-agbanwee ihe dịka otú ọ dị egwu na ngwugwu, ma ọ bụ ebe kemịkalị dị n'ime ebubo ya, ma ọ bụrụ na ọ nweghị ike imepe ọcha ma ọ bụ ghara imepụ. Ihe ndị a dị mfe karịrị mana ha bụ ihe kachasị mkpa maka obere oge nke ngwa.

Njikọta Mmetụta: Iyi Ọcha, Mmiri, na Mmetụta Oke Ogu

Ndị dị n'obodo ọchịchị ma ọ bụ ndị dabere na iyi odo na njem mkpisi mmiri enyere aka inwe nkịtị akpụkpọ gburugburu ebe obibi site na ngwaọrụ dị ka e-coating ma ọ bụ chromate conversion coatings. Ngwaọrụ a na-eme ka mmetụta akpụkpọ gburugburu ebe obibi ghara ịdị elu site na 60 ruo 90 percent dibu otu ebe ọ bụla e wezụghị akpụkpọ gburugburu ebe obibi. Mgbe anya ekwu oké ọgwụ ọgwụ pụrụ ichekarị karịa 300 degrees Fahrenheit, akpụkpọ ceramic-based na-achọpụta ọsọsọ mgbe ọ na-eji oke ogu na-aga n'ihu na-adịgboro adịgboro, ya mere ọ na-achọpụta ọsọsọ karịa akpụkpọ ọcha ma ọ bụ ndị ọzọ dịka akpụkpọ organic. Naanị mgbe e chọrọ imepepụ iyi n'ụlọ ọrụ, akpụkpọ powder coating na-abụkarị ihe mma maka ikwunti ozi, mgbe niile e kpaghịrị ya mgbe e mere akpụkpọ phosphate cleaning, nke na-enyere aka ime ka ha na-achọpụta ebe si na-agbado.

Ikwunti ozi vs. Nkịtị Akpụkpọ n'Ịmepụta Ndị Dị Otú I chọrọ n'Ịmepụta Die Cast

Ọrụ anodizing zuru oke n'obi otu egeri na otu dollar na iri abụọ otu egeri maka ọ bụla, mgbe ọ dị ka egeri ole na ole, mana n'ụzọ dị ukwuu ọ kwalite ego n'ụzọ nke ọma site na ịgha etiti ihe ndị a na-enwe, dị ka ngwaọrụ na-acha akpa ma ọ bụ ngwaongwu elwetronic. Mgbe onye otu enwere ike ịmepụta ihe dị elu, dị ka ise na anọchihara otu afọ na atọ, powder coating bụ isi iyi maka ego. O na-egbu egeri iri na ise ruo iri na asaa maka ọ bụla n'ihi na ọ na-acha akpa karịa ma mere mmetụta nta na mmemme n'ime ọrụ. Ihe ndị a pụghị ịhụrụ onye nnọchi anya nwere ike ịnweghị ihe dị ntakịrị dị ka sand blasting ma ọ bụ imepụta ihe chemika. Ndị a na-enye mmetụta dị mma mgbe ụfọdụ ma kpata ego site na iri anọ na iri na ise ruo iri anọ na iri na ise na iri na ise, dibu ya ha dị mma maka ihe ndị dị n'ime ngwaahịa ebe ihe a na-eme dị mkpa karịa ihe a na-ahụ.

FAQ

Kedu ihe ndi dị iche iche nke surface finishes maka die cast parts?

Ndị ọzọ na-eme ka ọdọ ọdọ gụnyere anodizing, powder coating, chemical conversion treatments, na e-coating. Otú ọ dị na ibe ya n'usoro corrosion resistance, wear resistance, na ike imebi akpụrụ akpọ.

Kedu otú surface finishing ekwekọrị durability nke die cast parts?

Surface finishing enyere durability siteere protective coatings pụrụ ikpebi corrosion, wear, na njedebe mmadụ. Nke a na-enyere oge ole na parts, nyebe ego maka ntughari na ntaramahụhụ.

Ọ bụ ezie na surface finishes nwere ike ime mbaara maka ngwaọrụ kpamkpam?

Ee, surface finishes nwere ike ime mbaara maka inye ngwaọrụ kpamkpam site na ịhọrọ materials, colors, na ụdị treatment. Nke a na-akwalite performance na oge ole n'ime mkpọtụ aka dị iche iche.

Kedu ihe dị iche gbasara anodizing na powder coating?

Iji anodizing, ekekọrọ akara oksịda nta na aluminimụ, na-enye usoro mma maka imejọ na ngwa ngwa akara. Iji powder coating, ekekọrọ akara polimer dị ukwuu, na-enye usoro mma maka imejọ na iwu agwa.

Ọ bụrụ na ị chọọ ịdị ndụ, ka ịmee mkpebi gbasaa akara?

Achịcha akara ọhụrụ karịrị ihe dị otú ahụ dị mma maka aṅụrị, jiri usoro ekebi VOC dị nta. Usoro dị ka powder coating na e-coating karịrị ikwe omume ma buru ibe ya maka nghọta ọha mmadụ, na-eme ka ha bụrụ isi mkpebi maka inweta ihe.

Ndepụta nke ọdịnaya

- Kedu ka Ndịdịta Gburugburu Nyere aka Mmetụta Die Cast Nyere Obodo na Obodo

- Anodizing na Powder Coating: Ndị pere mpe nke ịkpọpụta akpa

- Ihe Ndị Dị Otú Chemistri Na Mekanik Iji Mee Nkwado Karịa Nke O Di Ulu

- Ịgbapụta na E-Coating: Meezie obi na njikọta aturu aturu

- Ịhọrọ Ọkpụkpọ Ọdịdị Ebe Gbasara Ihe Nkiri

-

FAQ

- Kedu ihe ndi dị iche iche nke surface finishes maka die cast parts?

- Kedu otú surface finishing ekwekọrị durability nke die cast parts?

- Ọ bụ ezie na surface finishes nwere ike ime mbaara maka ngwaọrụ kpamkpam?

- Kedu ihe dị iche gbasara anodizing na powder coating?

- Ọ bụrụ na ị chọọ ịdị ndụ, ka ịmee mkpebi gbasaa akara?